Method for combination preparation of CuO/CeO2/gamma-Al2O by use of ultrasound-plasma

A plasma and combined preparation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of easy agglomeration of catalysts, affecting catalyst activity and strength, Carrier skeleton is easy to break and other problems, to achieve the effect of increased dispersion, reduced cost, and improved activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

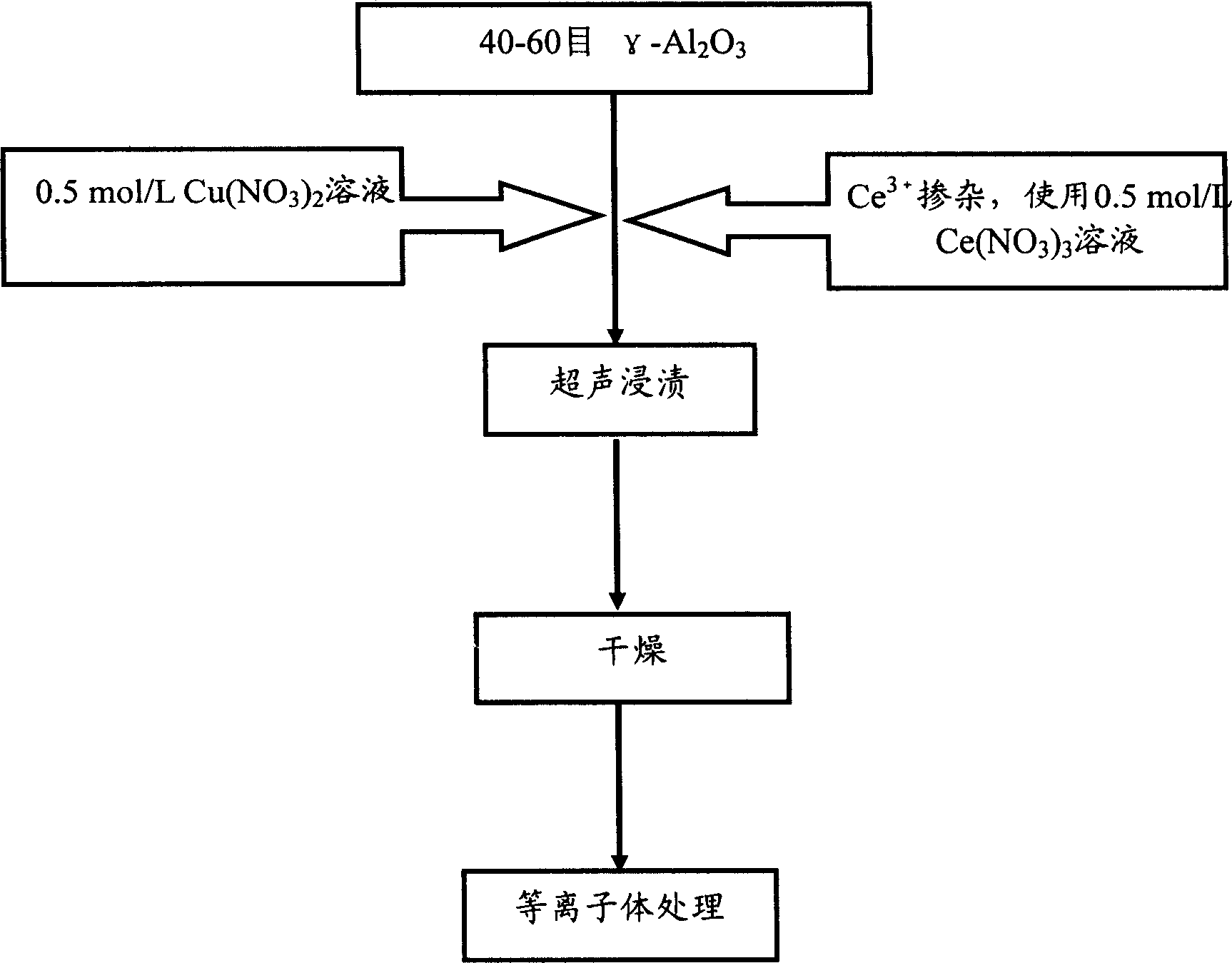

[0030] The particle size is 40-60 mesh γ-Al 2 o 3 5 grams of particles were added to Cu(NO 3 ) 2 and 0.5mol / l Ce(NO 3 ) 3 According to the mixed solution of 23ml and 5ml, put it into an ultrasonic cleaner, and carry out ultrasonic impregnation at 30°C, the ultrasonic radiation frequency is 25kHz, the ultrasonic power is 240W, and the ultrasonic action time is 20min; then the sample is removed from the ultrasonic cleaner Take it out, filter, dry at 120°C for 2 hours, then put the dried particles in a radio frequency TCP plasma treatment device, and perform plasma treatment for 20min at a power of 200W to obtain CuO / CeO of the present invention 2 / γ-Al 2 o 3 Catalyst (labeled CuCeO-Us-Plas).

Embodiment 2

[0032] The particle size is 40-60 mesh γ-Al 2 o 3 5 grams of particles were added to Cu(NO 3 ) 2 and 0.5mol / l Ce(NO 3 ) 3 According to the mixed solution of 23ml and 5ml, put it into an ultrasonic cleaner, and carry out ultrasonic impregnation at 5°C, the ultrasonic radiation frequency is 10kHz, the ultrasonic power is 40W, and the ultrasonic action time is 1min; Take it out, filter, and dry at 140°C for 3 hours, then put the dried particles in a radio frequency TCP plasma treatment device, and perform plasma treatment at 1W for 1min to prepare CuO / CeO 2 / γ-Al 2 o 3 Catalyst (labeled CuCeO-Us-Plas).

Embodiment 3

[0034] The particle size is 40-60 mesh γ-Al 2 o 3 5 grams of particles were added to Cu(NO 3 ) 2 and 0.5mol / l Ce(NO 3 ) 3 According to the mixed solution of 23ml and 5ml, put it into an ultrasonic cleaner, carry out ultrasonic impregnation at 50°C, the ultrasonic radiation frequency is 100kHz, the ultrasonic power is 1000W, and the ultrasonic action time is 120min; then the sample is removed from the ultrasonic cleaner Take it out, filter, dry at 120°C for 2 hours, put the dried particles in a radio frequency TCP plasma treatment device, and perform plasma treatment for 120min at a power of 1200W to obtain CuO / CeO of the present invention 2 / γ-Al 2 o 3 Catalyst (labeled CuCeO-Us-Plas).

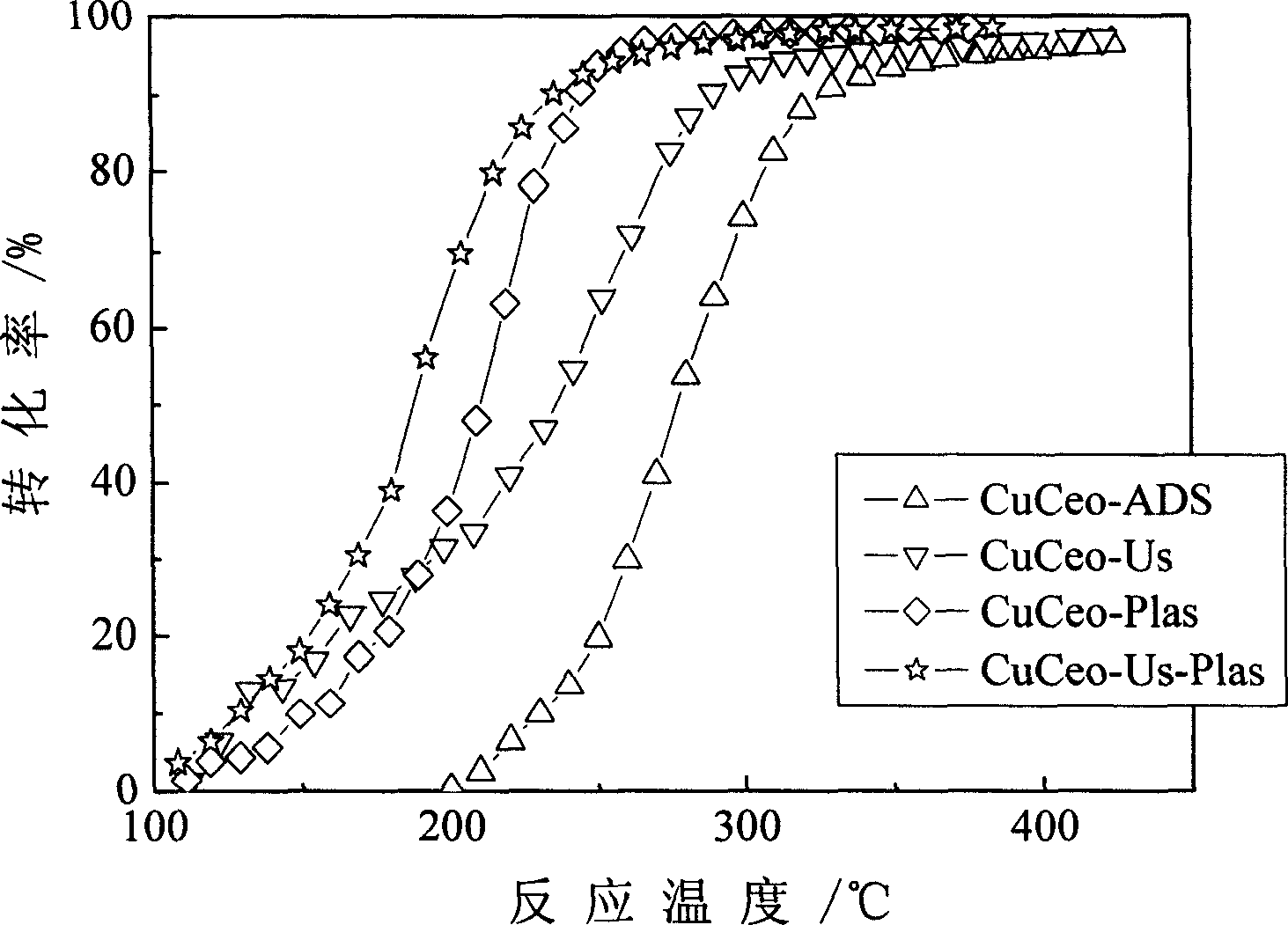

[0035] The catalyst CuO / CeO prepared by the above-mentioned embodiment of the present invention and the prior art common impregnation method are prepared below 2 / γ-Al 2 o 3 (marked as CuCeO-ADS) catalytic activity compares; Simultaneously for further illustrating the effect of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com