Polyacrylic acid super absorbent resin containing illite and fly ash and preparation method

A technology of superabsorbent resin and polyacrylic acid, which is applied in the field of superabsorbent composite materials and its preparation, can solve the problems of low water absorption, poor salt resistance, environmental impact, etc., and achieve the effects of improving fertility, facilitating release, and improving soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

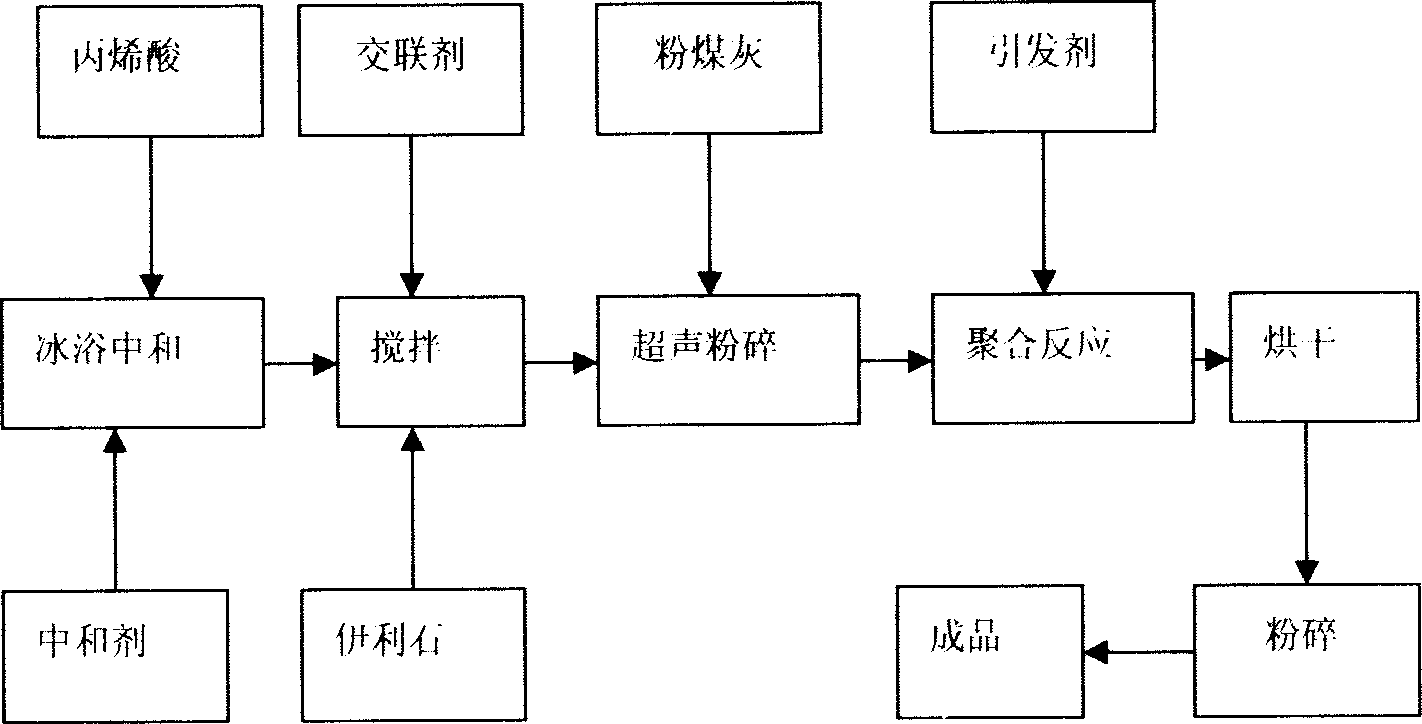

[0042] Such as figure 1 Process, take 4g of acrylic acid monomer and dissolve it in a beaker, under the condition of ice bath, 8.441 grams of NaOH solution with a mass percentage of 25% is added dropwise to acrylic acid by a neutralization degree of 95% (mol percentage), and continuously Then add 0.0032 grams of N, N-methylenebisacrylamide to the resulting solution and stir for a few minutes until the crosslinking agent is completely dissolved; then add 0.6 grams of illite, stir until the illite is evenly dispersed, and then add pulverized coal 0.6 gram of ash, stir until the fly ash is uniformly dispersed to obtain a mixed solution; the gained mixed solution is ultrasonically dispersed (the power of the ultrasonic generator is 200-4000 watts, the frequency of the ultrasonic wave is 100 kilohertz-300 megahertz, and the ultrasonic time is 2 -15 minutes), take out and stir, and circulate ultrasonic pulverization and stirring to obtain a mixture with considerable viscosity; add 0...

Embodiment 2

[0044] Weigh 4g of acrylic acid monomer and dissolve it in a beaker. Under the condition of ice bath, 8.441 grams of NaOH solution with a mass percentage of 25% is added dropwise to acrylic acid with a neutralization degree of 95% (mol percentage), and continuously stirred ; Add 0.0044 g of N, N-methylenebisacrylamide to the resulting solution and stir for several minutes until the crosslinking agent is completely dissolved; then add 0.8 g of illite, stir until the illite is evenly dispersed, and then add 0.8 gram of fly ash gram, stir until the fly ash is uniformly dispersed to obtain a mixed solution; the gained mixed solution is dispersed through ultrasonic (the power of the ultrasonic generator is 200-4000 watts, the frequency of the ultrasonic wave is 100 kilohertz-300 megahertz, and the ultrasonic time is 2-15 Minutes), take out and stir, circulate ultrasonic pulverization and stirring to obtain a mixture with considerable viscosity; add 0.0160 g of ammonium persulfate in...

Embodiment 3

[0046] Weigh 4g of acrylic acid monomer and dissolve it in a beaker, and add 8.886 grams of 25% NaOH solution to the acrylic acid drop by drop according to the neutralization degree of 100% (mol percentage) under the condition of ice bath, and constantly stir Add 0.0044 g of N, N-methylenebisacrylamide to the resulting solution and stir for a few minutes until the crosslinking agent is completely dissolved; then add 0.4 g of illite, stir until the illite is evenly dispersed, and then add 0.4 gram of fly ash gram, stir until the fly ash is uniformly dispersed to obtain a mixed solution; the gained mixed solution is dispersed through ultrasonic (the power of the ultrasonic generator is 200-4000 watts, the frequency of the ultrasonic wave is 100 kilohertz-300 megahertz, and the ultrasonic time is 2-15 Minutes), take out and stir, and circulate ultrasonic pulverization and stirring to obtain a mixture with considerable viscosity; add 0.0180 g of ammonium persulfate into the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com