Circulating fluidized bed reactor

A fluidized bed reactor and fluidized bed technology, applied in fluidized bed heat exchangers, fluidized bed combustion equipment, chemical instruments and methods, etc., can solve the problem that the residence time of solid material flow is no longer sufficient and the cooling efficiency is reduced. and other problems, to achieve the effect of low cost, reduced free space height, and compact structure height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

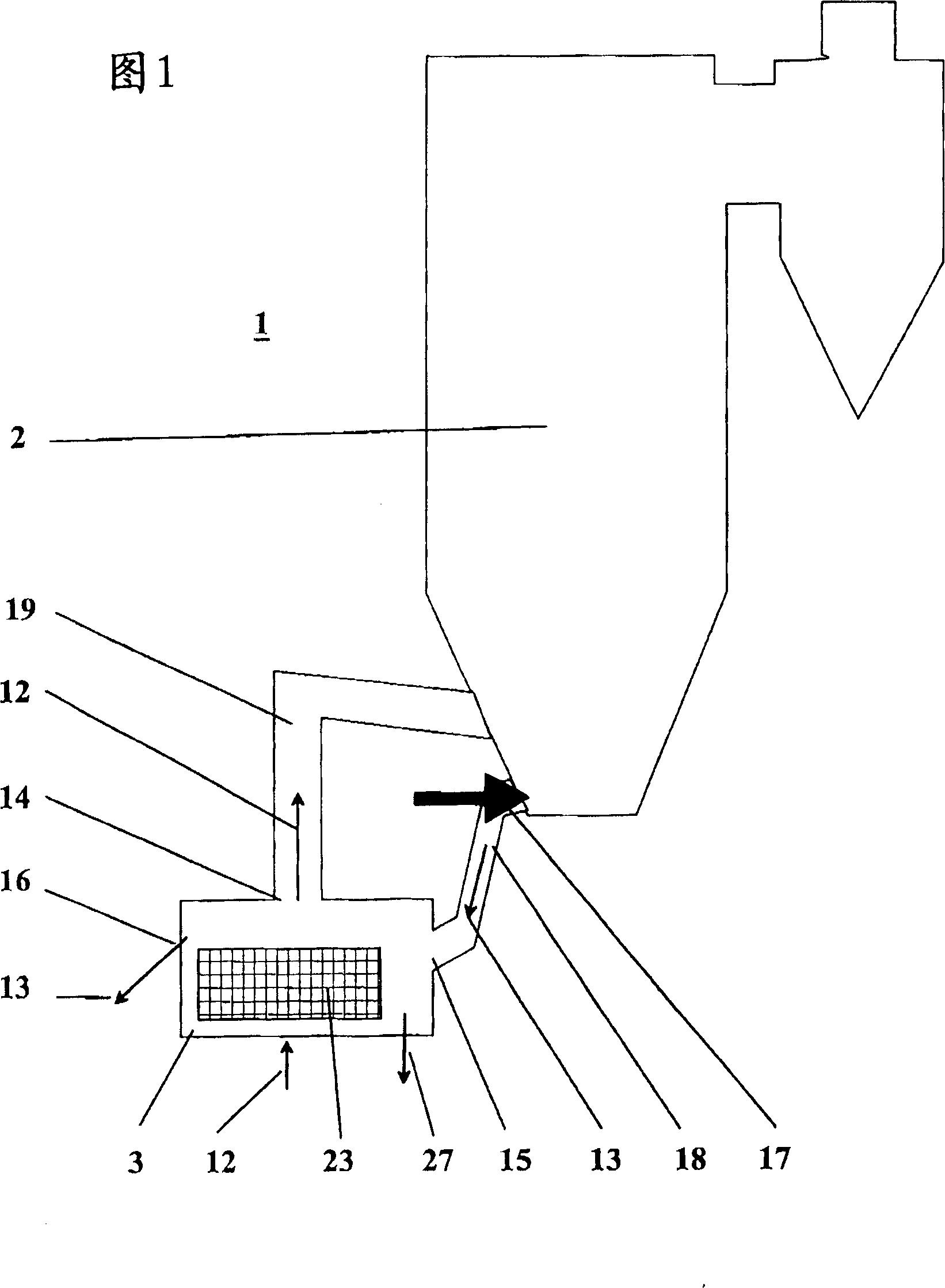

[0034] Figure 1 schematically shows a circulating fluidized bed reactor 1 having a reactor chamber or combustion chamber 2 in which solid lump fuels, such as coal, waste, biomass, etc., are combusted in the fluidized bed, and having A fluidized bed cooler or solid matter cooler 3 connected to the combustion chamber 2 . The ash 13 produced during the combustion accumulates for the most part on the bottom of the combustion chamber 2 and the remainder of the ash flows out of the combustion chamber 2 and is removed via the fluidized bed cooler 3 . The ash 18 flows out of the combustion chamber 2 via a cooler filling line 18 , which connects the combustion chamber 2 via a solids inlet 15 to the cooler 3 . An ash regulating fitting 17 is arranged at the outlet of the combustion chamber 2 to regulate the flow 13 of solid matter flowing out into the cooler 3 .

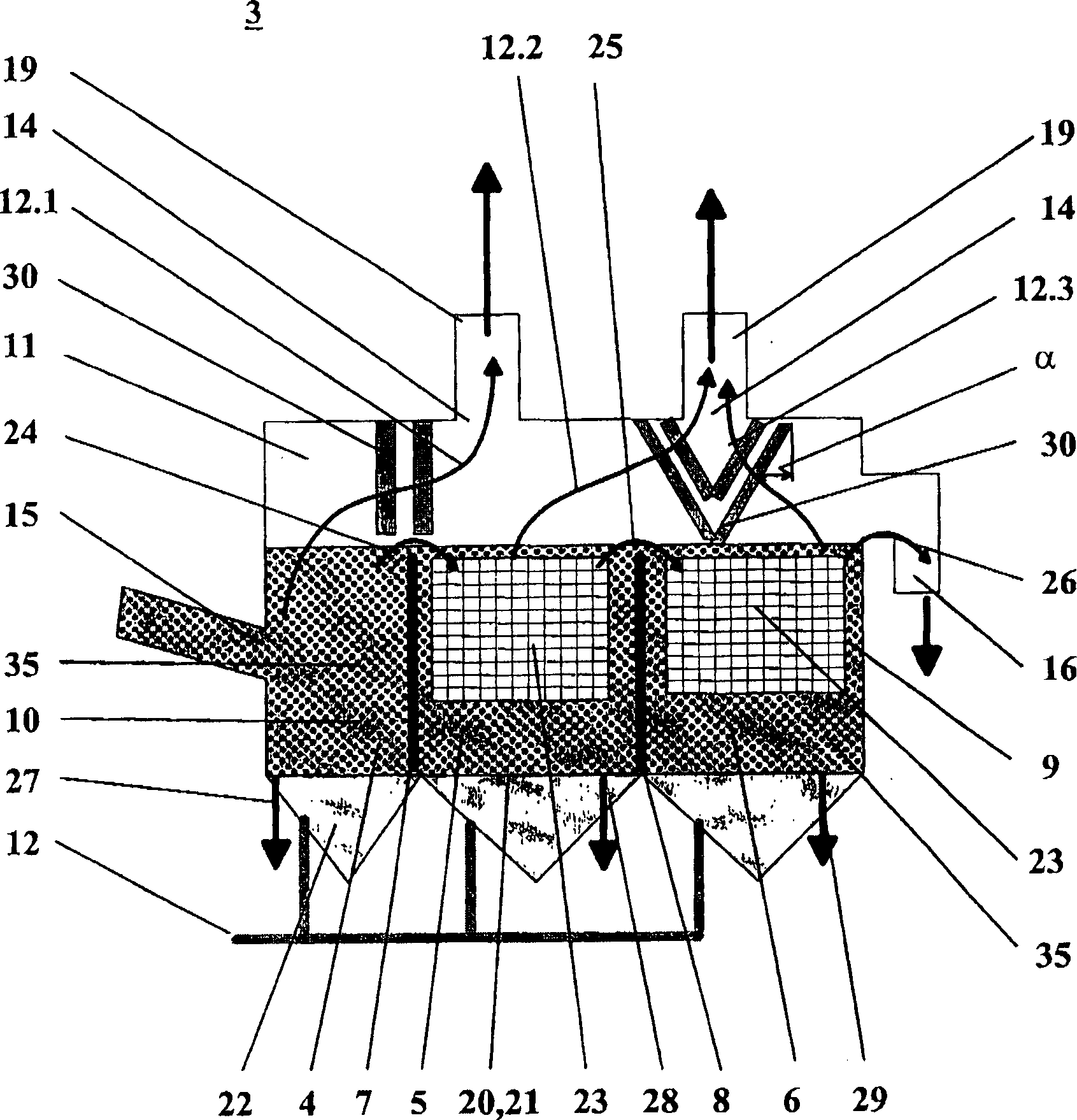

[0035] In order to cool the ash or solid matter 13, the fluidized bed cooler 3 is provided with one or more swirl chambers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com