Automatic metering device for oil, water and gas three-phase flow

An automatic metering and three-phase flow technology, which is applied in volume flow measuring devices, measuring devices, volume metering, etc., can solve the problems of reduced measurement accuracy and achieve the effects of high measurement accuracy, wide viscosity range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with accompanying drawing:

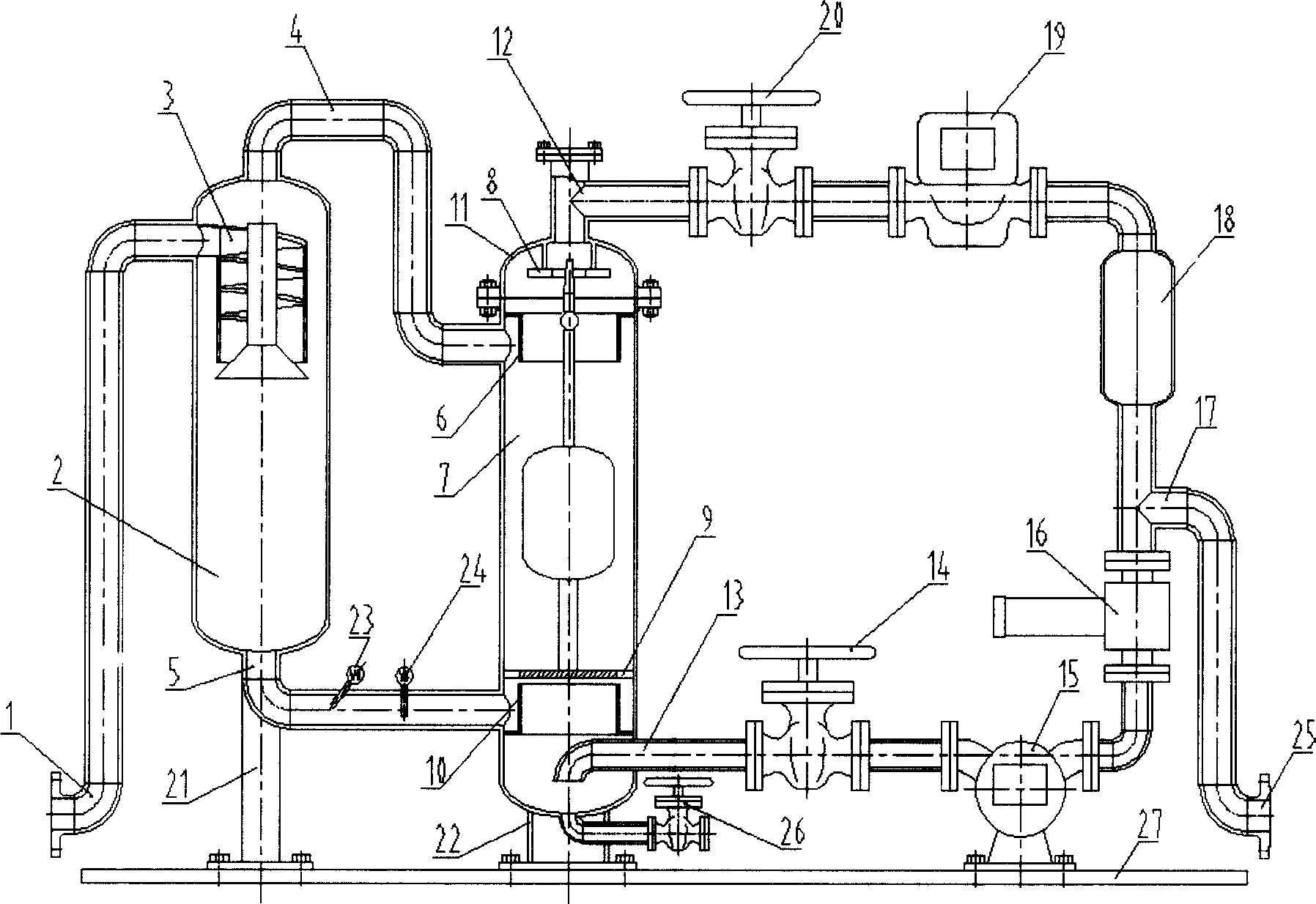

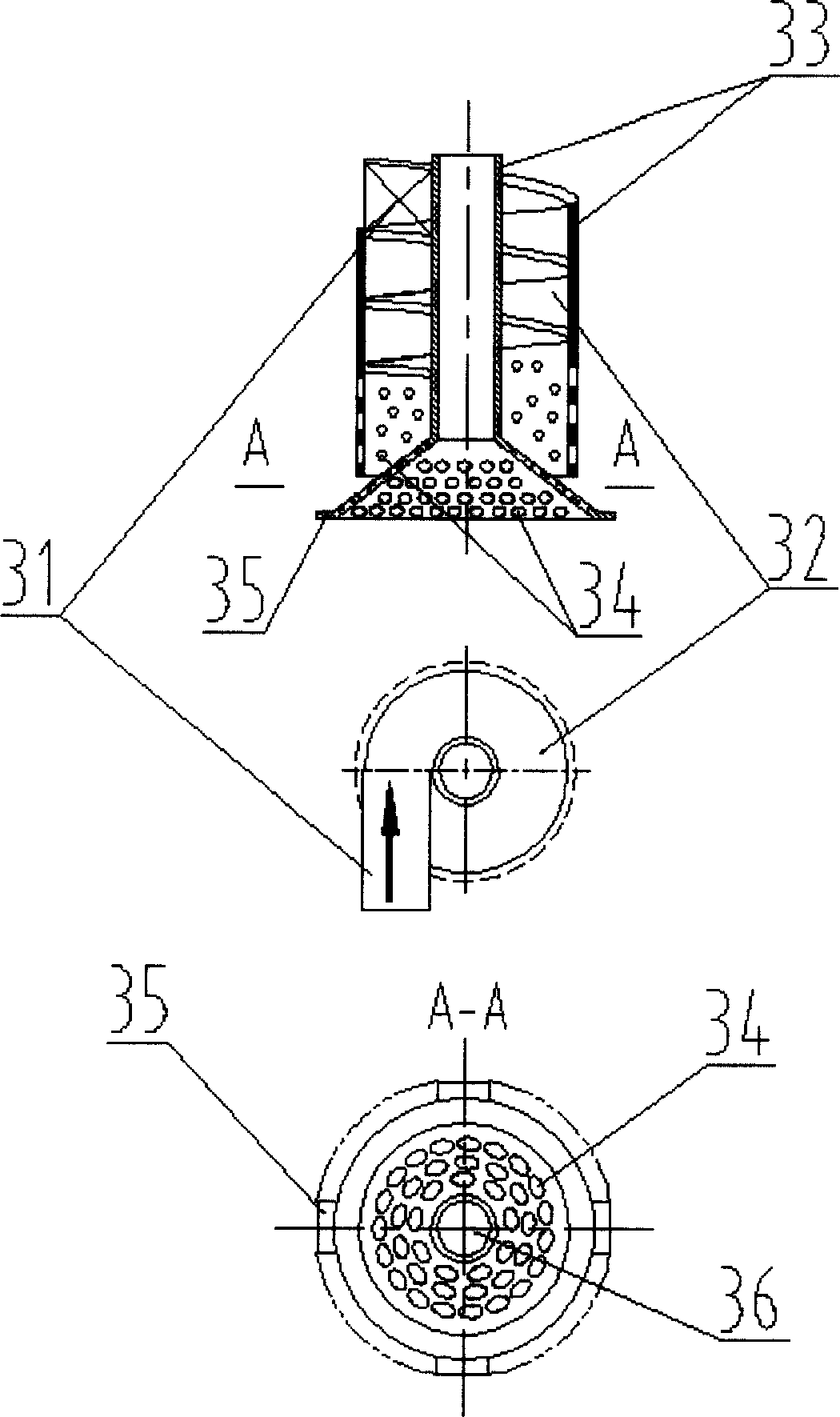

[0045] Such as figure 1 As shown, the gas-liquid mixture enters the cyclone centrifugal separator 3 placed in the gas-liquid separation tank 2 from the gas-liquid inlet pipe 1 through the cyclone separator inlet 31, and the gas-liquid separation is initially realized through the separation of the cyclone centrifugal separator 3 The gas-containing liquid separated by the cyclone centrifuge tube 32 continues to be centrifuged along the guide separation sleeve 33 under the action of inertia—gravity and centrifugal force, and falls down to the gas-liquid separation screen placed at the lower end of the guide separation sleeve 33 35, the liquid sieved by the gas-liquid separation sieve 35 flows down the inner wall of the gas-liquid separation tank 2, and the gas flows up to the gas discharge pipe 4 at the top of the gas-liquid separation tank 2, and thus passes through the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com