Polarized light converter, method for fabrication and backlight component

A technology of backlight module and manufacturing method, which is applied to optics, instruments, optical components, etc., can solve problems such as time-consuming, difficult material selection, cumbersome assembly, etc., and achieve the effect of simple manufacturing method, easy material selection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

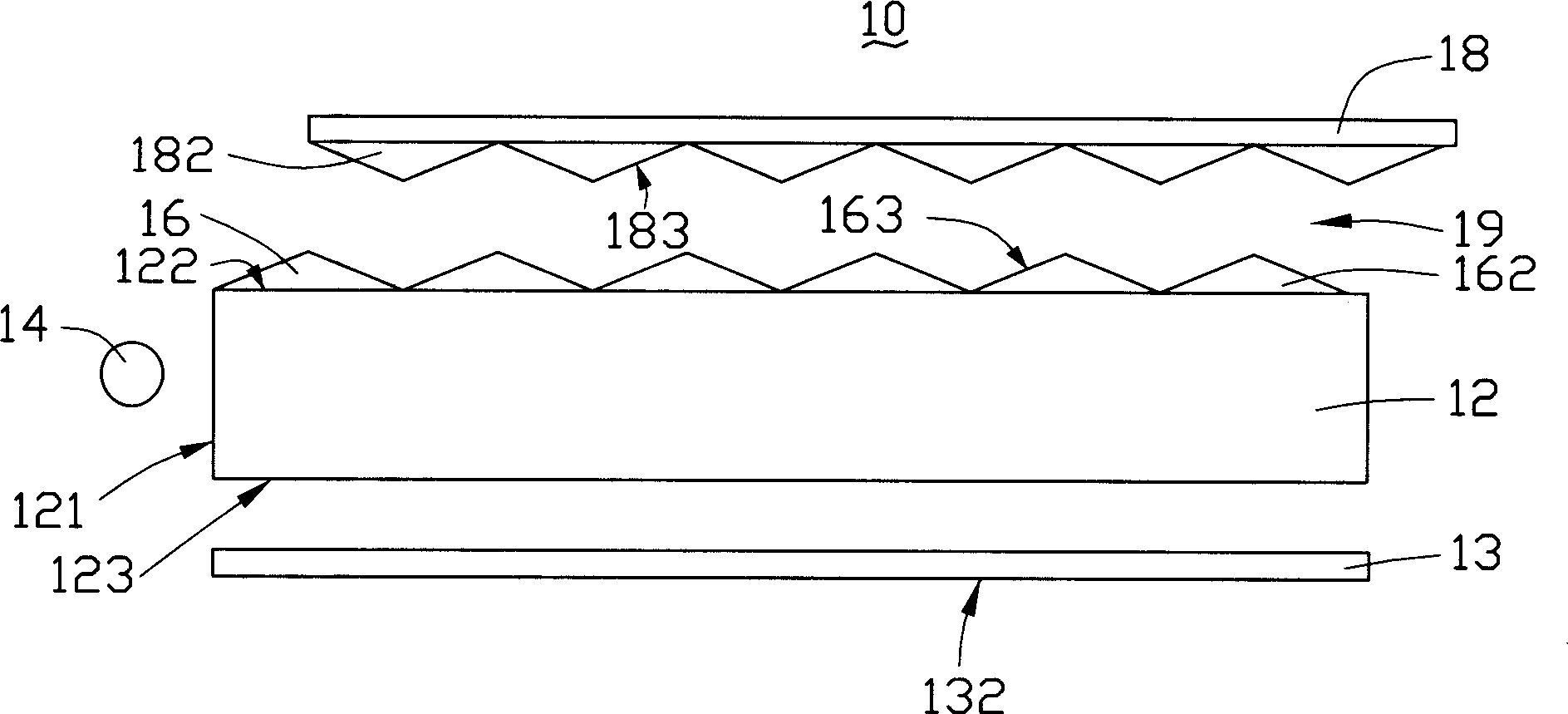

[0017] The polarized light converter, the manufacturing method of the polarized light converter and the backlight module using the polarized light converter of the present invention will be further described in detail below with reference to the accompanying drawings.

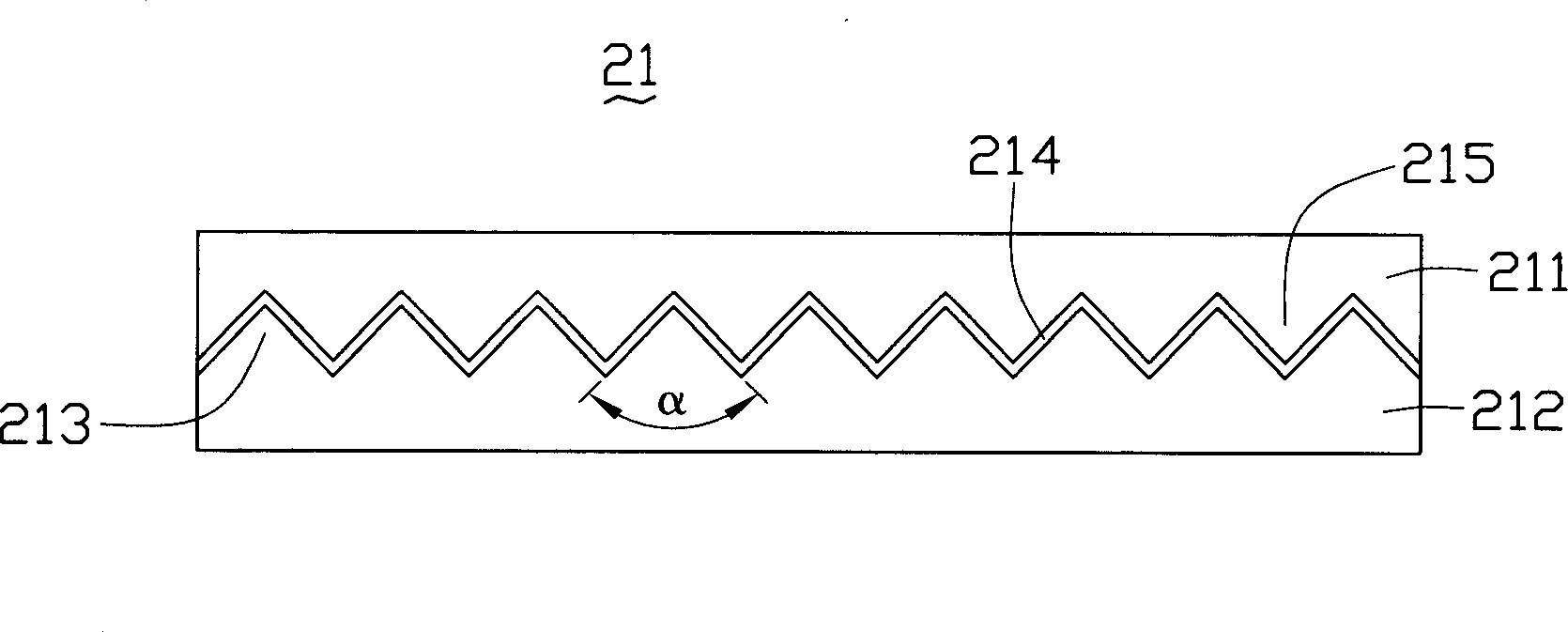

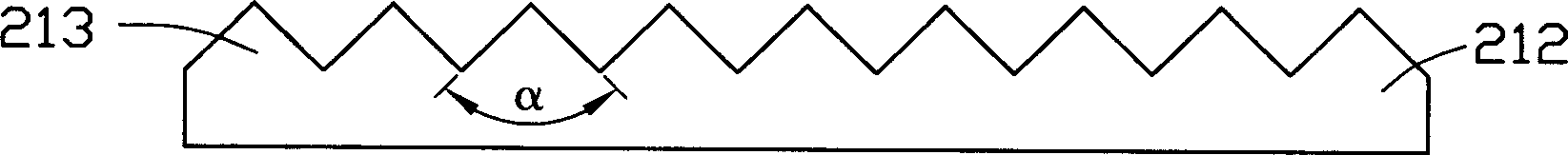

[0018] see figure 2 The polarized light converter 21 of the present invention includes an upper prism plate 211 with several microprisms 215 , a lower prism plate 212 with several microprisms 213 and a polarization splitting film 214 . Some microprisms 213 vertex angle α of lower prism plate 212 are 90 degree, and this upper and lower prism plate 211,212 materials are identical, can be glass or plastic translucent material, and this polarized light splitting film 214 material is magnesium difluoride ( MgF 2 ), silicon dioxide (SiO 2 ), tantalum pentoxide (Ta 2 o 5 )Wait. The upper and lower prism plates 211, 212 sandwich the polarizing beam splitting film 214 therebetween and combine to form an integrated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com