Cutting tool clamp and cutting tool

A technology for cutting blades and cutting tools, which is applied in the direction of manufacturing tools, tool holder accessories, milling cutters, etc., can solve the problems of prolonging working hours and increasing working costs, and achieve the effect of reducing weight, reducing weight and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

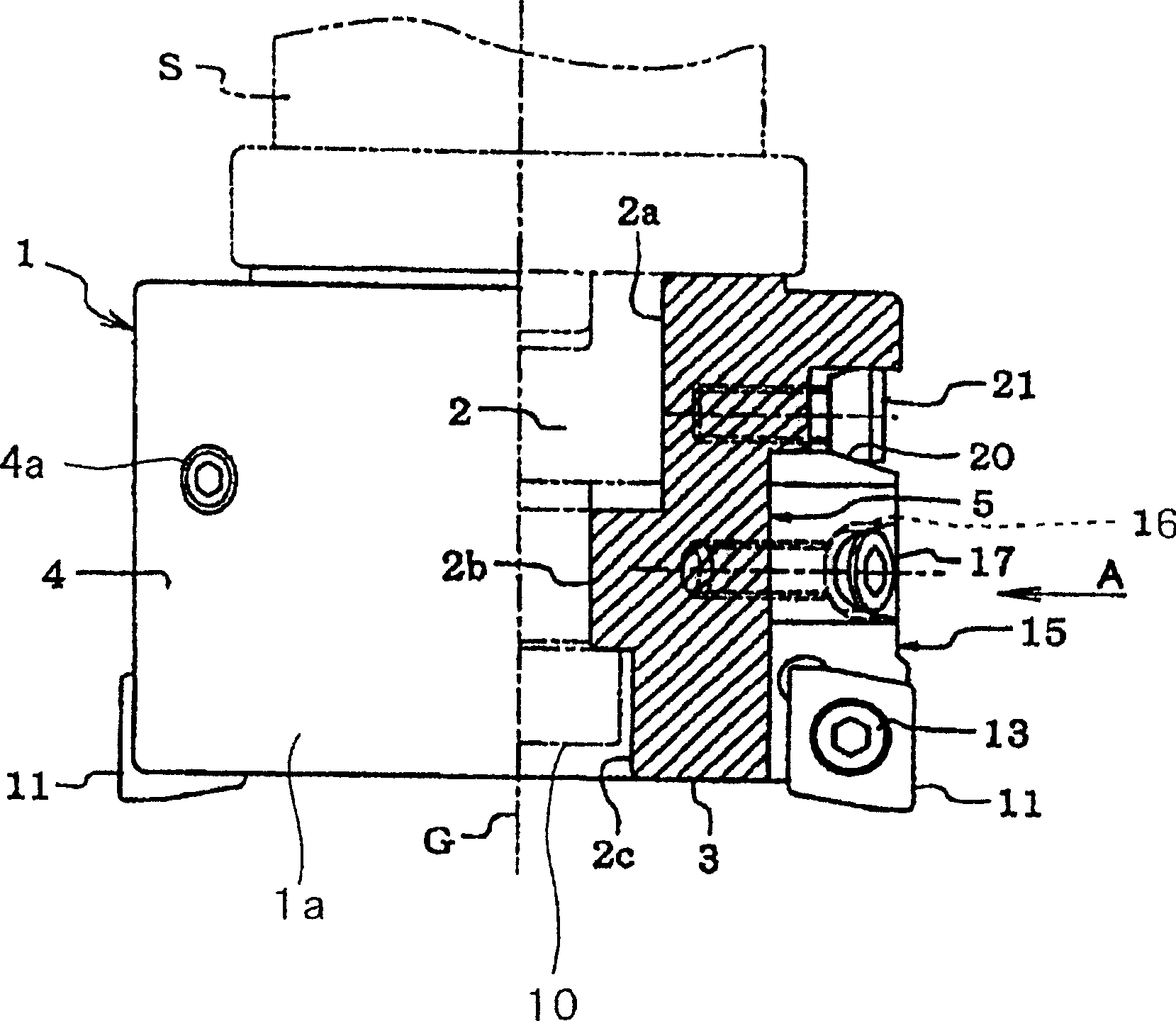

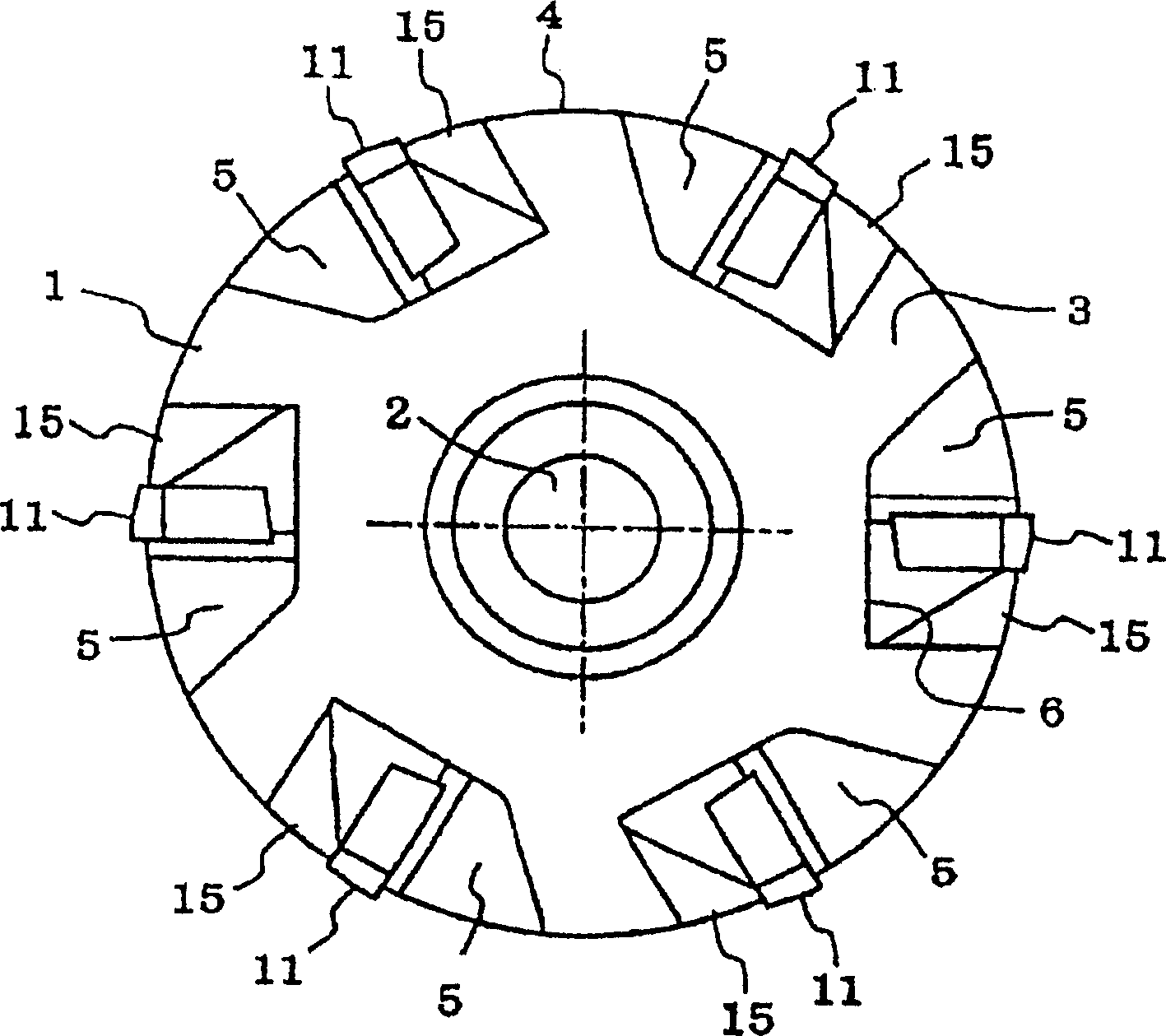

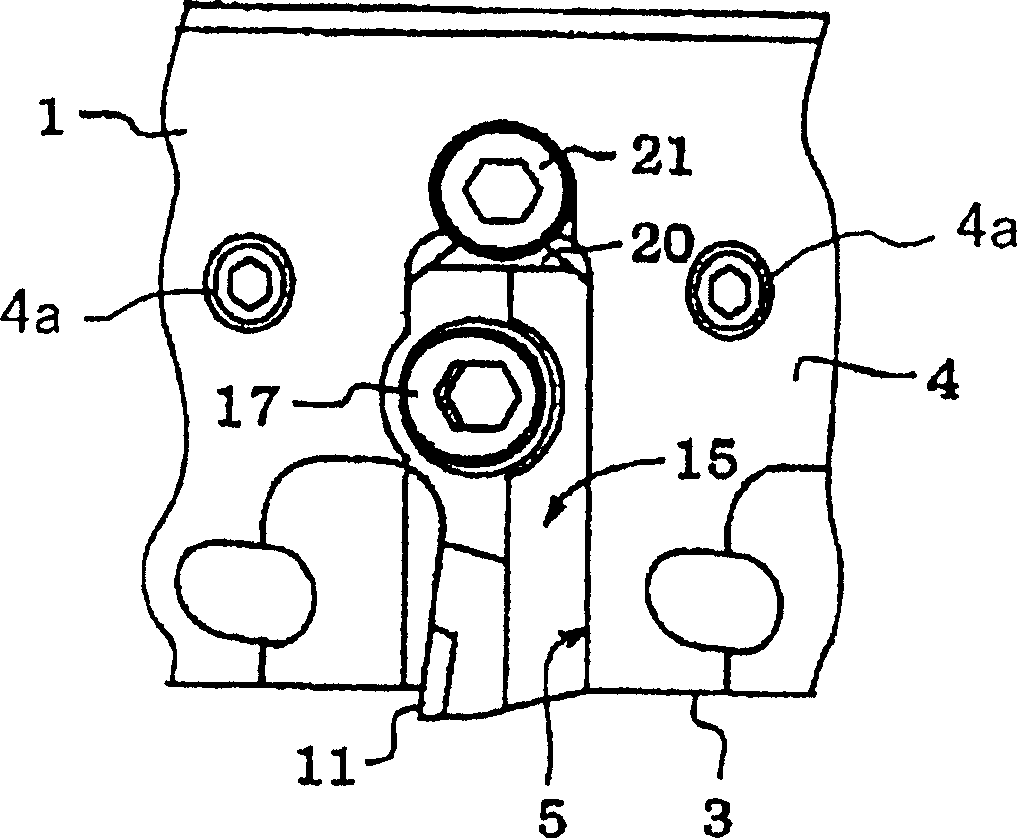

[0160] We will detail one of the best embodiments of the cutting insert holder and cutting tool and use as an example a rotating cutting tool which is a face milling cutter such as Figure 1-4 shown.

[0161] figure 1 is a partial cutaway front view of a rotary cutting tool. figure 2 yes figure 1 Bottom plan view of the rotary cutting tool in . image 3 is when viewed in the direction of arrow A figure 1 Partial side view of the tool in . Figure 4 is an enlarged view showing an internally threaded member, which is a threaded coil, such as HELI-SERT(R) or Heli-Coil(R) in this example, fixedly embedded in the cutting insert holder.

[0162] In the drawings, reference numeral 1 denotes a plastic rotary cutting blade holder. The types of plastics and the method of producing the cutting insert holder 1 will be described later in this embodiment.

[0163] as by figure 1 with 2 As can be seen in , the cutting insert holder 1 has a cylindrical base 1a. In the central part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com