Headlamp for vehicle

一种前照灯、车辆的技术,应用在车辆照明系统、车头灯、道路车辆等方向,能够解决恶化、易变为高温等问题,达到缩短前后长度、实现结构紧凑化、增加利用光束的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Embodiments of the present invention will be described in detail below using the drawings.

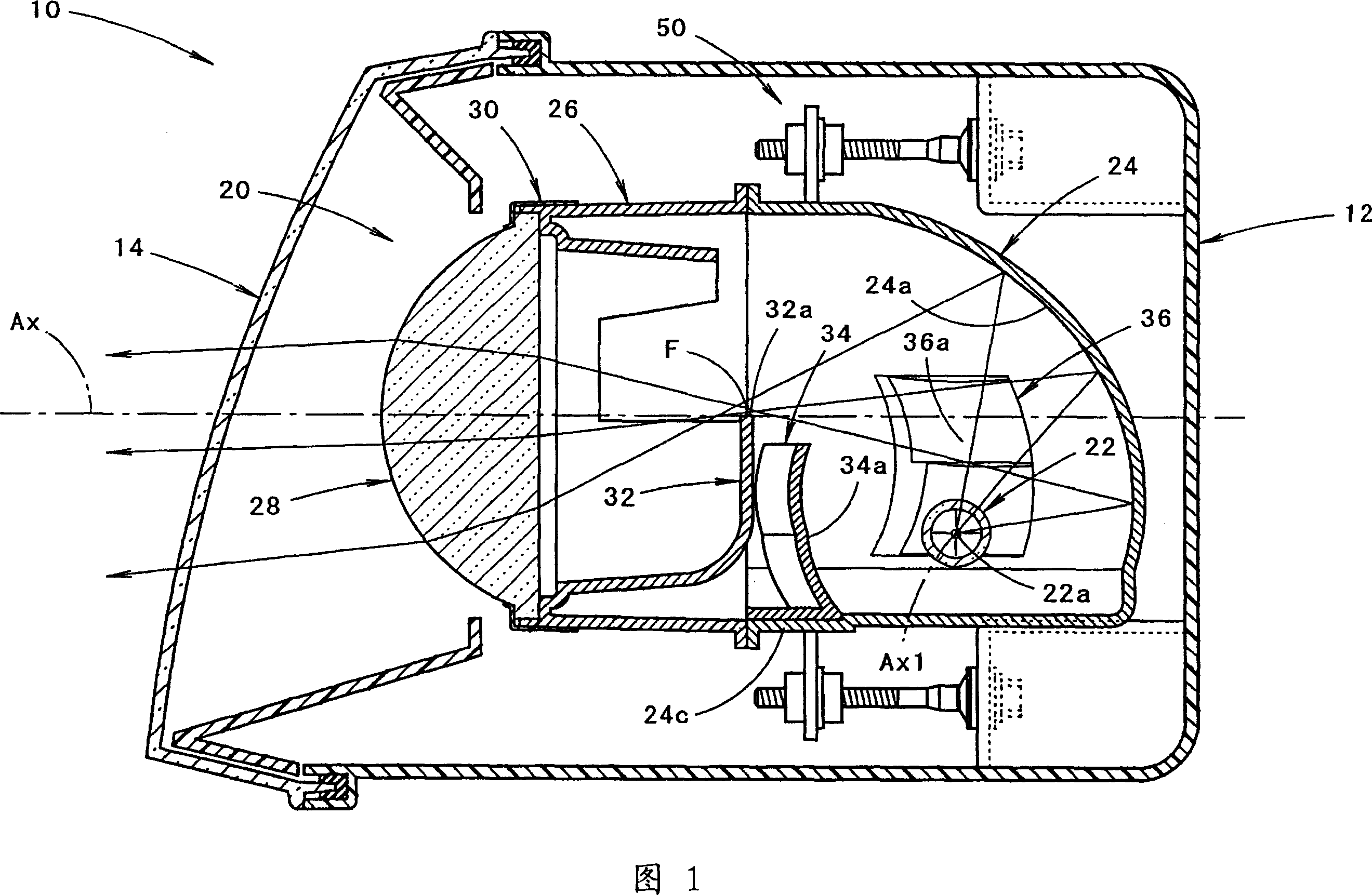

[0079] FIG. 1 is a side sectional view showing a vehicle headlamp 10 according to an embodiment of the present invention.

[0080] As shown in FIG. 1 , the vehicle headlight 10 is a vehicle headlight installed on the right front end of the vehicle, and the lamp unit 20 having an optical axis Ax extending in the front-rear direction of the vehicle can be moved up and down by an alignment mechanism 50 . It is accommodated in a lamp chamber formed by a lamp body 12 and a transparent light-transmitting cover 14 mounted on the front end opening thereof so as to be tilted in the direction and left and right directions.

[0081] At a stage after the alignment adjustment by the alignment mechanism 50 is completed, the optical axis Ax of the lamp unit 20 extends in a downward direction of about 0.5-0.6° with respect to the vehicle front-rear direction.

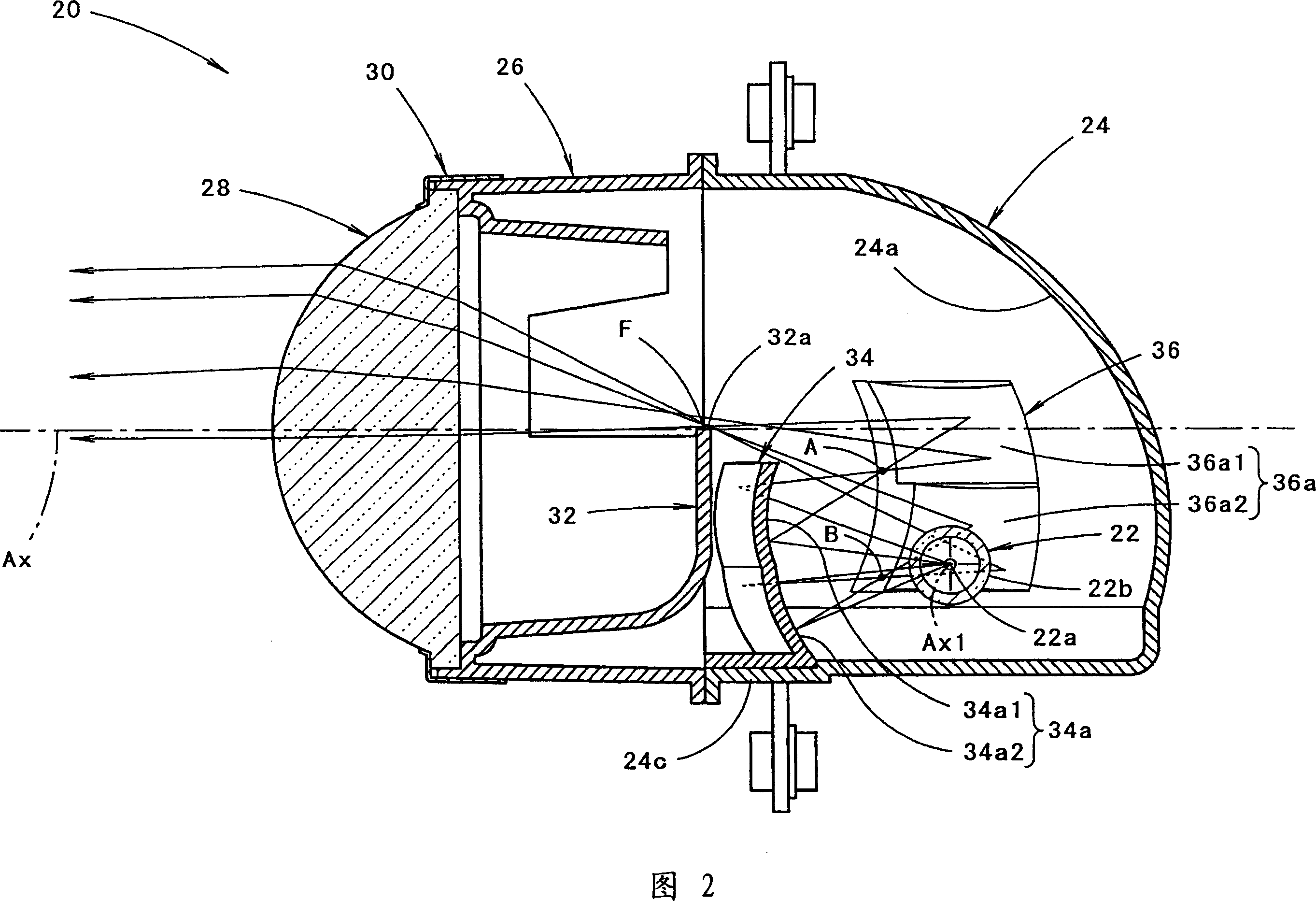

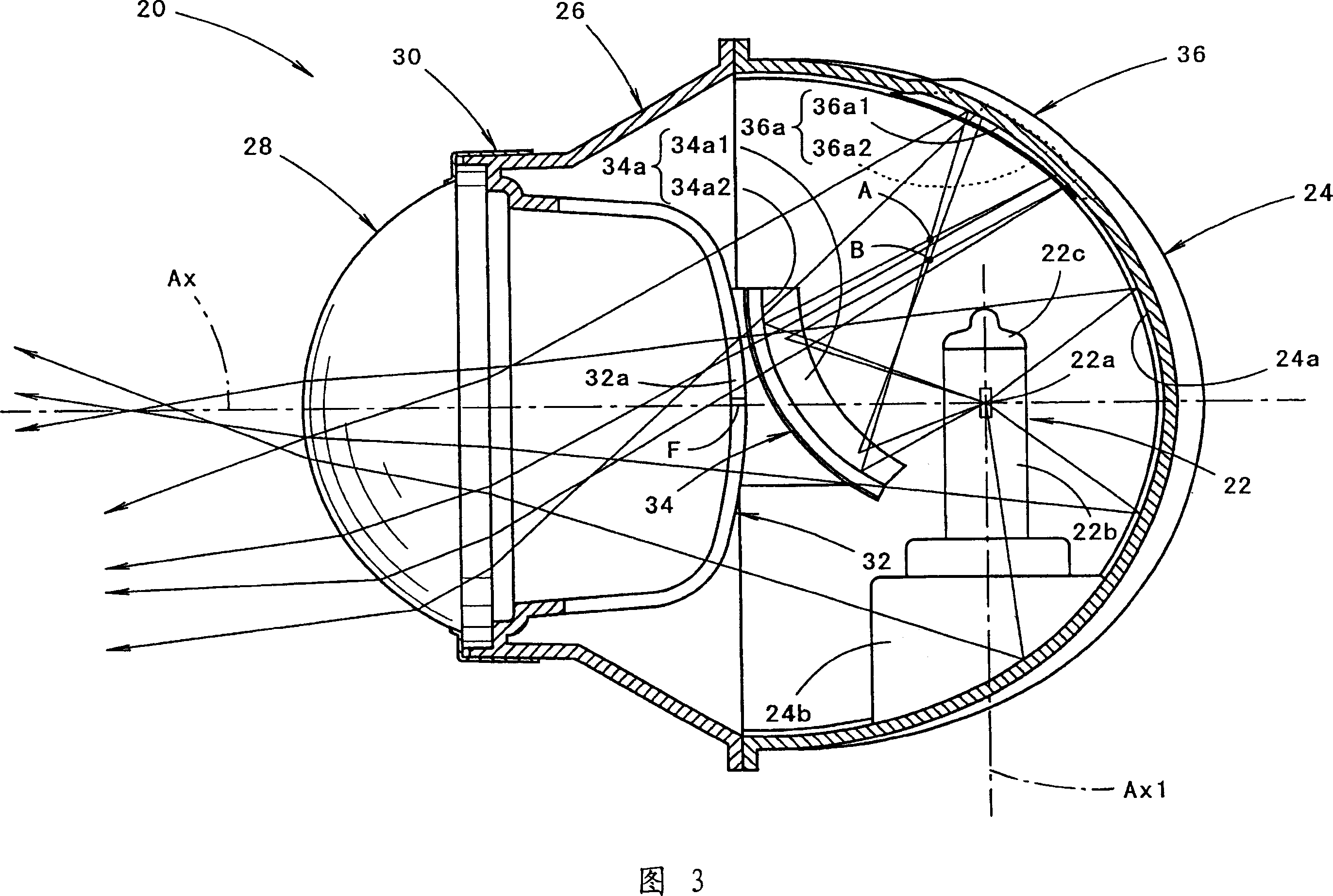

[0082] 2 and 3 are side sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com