Method of treating red mud by extracting Bayer method mother liquid

A Bayer process red mud and Bayer process technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of reducing environmental hazards, improving dissolution efficiency and solution yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

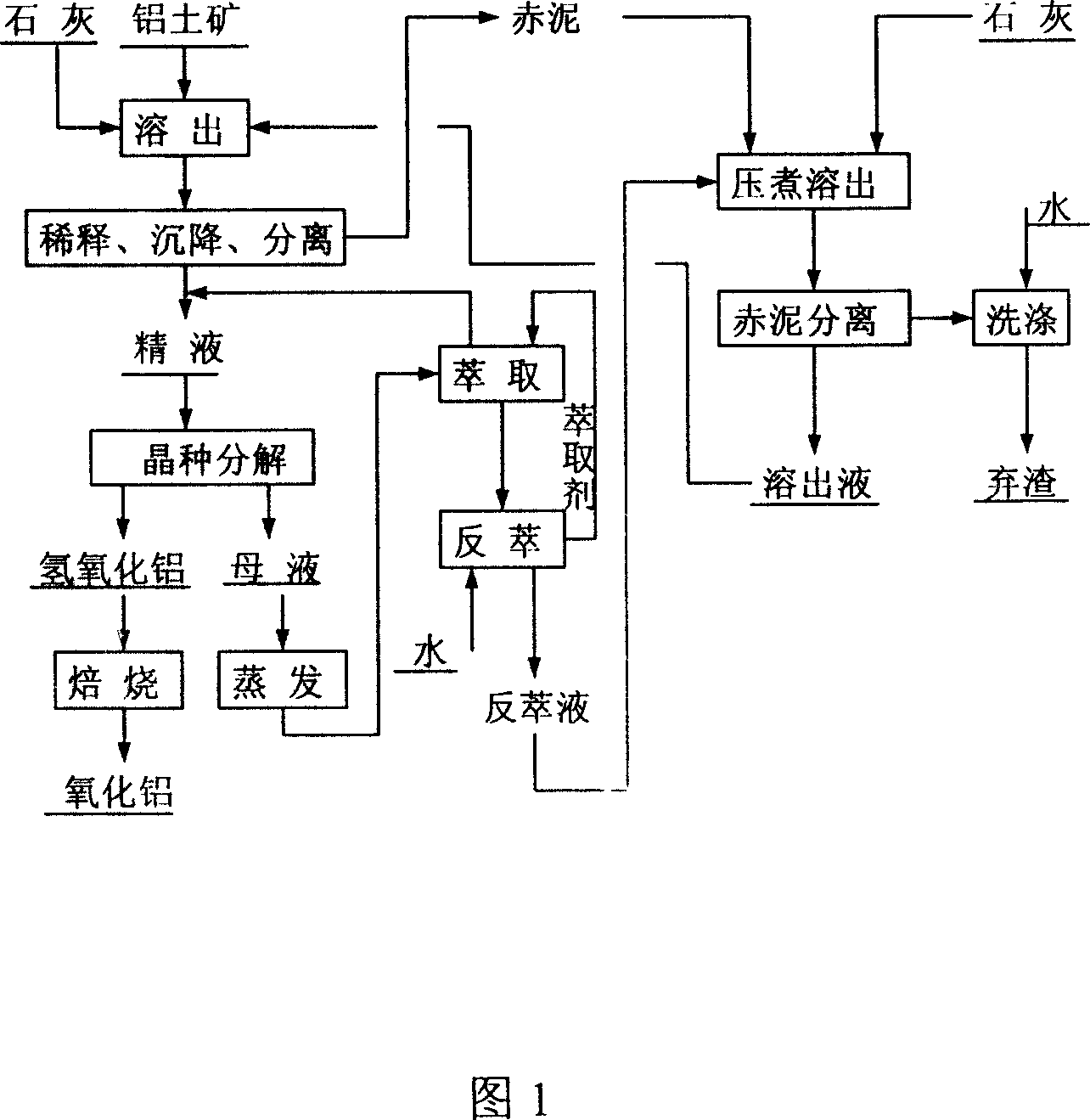

Image

Examples

Embodiment 1

[0023] Extraction and stripping. Use fatty alcohol with a carbon chain length of 8-10 as the extraction agent to extract the concentration N K Be the evaporated mother liquor of 320g / L, back-extract with water, extraction temperature is 90 ℃, back-extraction temperature is 85 ℃; Extraction ratio (oil: water volume ratio) is 1: 1, back-extraction ratio (oil: water) is 2:1; the number of extraction stages is 40, and the reaction time of each stage is 3 minutes; the number of stripping stages is 7 stages, and the reaction time of each stage is 5 minutes. Stripping liquid N after stripping K 240g / L, caustic ratio α K It is 43 (the small part of aluminum contained is caused by incomplete extraction and separation).

Embodiment 2

[0025] Extraction and stripping. Use fatty alcohol with a carbon chain length of 8-10 as the extraction agent to extract the concentration N K Be the evaporated mother liquor of 320g / L, back-extract with water, extraction temperature is 85 ℃, back-extraction temperature is 80 ℃; Extraction ratio (oil: water volume ratio) is 1: 1, back-extraction ratio (oil: water) is 3:1; the number of extraction stages is 35, the reaction time of each stage is 5 minutes, the number of stripping stages is 6 stages, and the reaction time of each stage is 10 minutes. Stripping liquid N after stripping K 255g / L, caustic ratio α K It is 44.2 (the small amount of aluminum contained is caused by incomplete extraction and separation).

Embodiment 3

[0027] Extraction and stripping. Use n-octanol as extractant to extract concentration N K Be the evaporated mother liquor of 320g / L, back-extract with water, extraction temperature is 75 ℃, back-extraction temperature is 70 ℃; Extraction ratio (oil: water volume ratio) is 2.5: 1, back-extraction ratio (oil: water) is 3:1; the number of extraction stages is 20, and the reaction time of each stage is 12 minutes; the number of stripping stages is 8, and the reaction time of each stage is 12 minutes. Stripping liquid N after stripping K 244g / L, caustic ratio α K It is 41.3 (the small amount of aluminum contained is caused by incomplete extraction and separation).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com