Hydraulic gripper for gas extraction, drainage and discharge driller

A hydraulic clamping and drilling rig technology, which is applied in the direction of gas discharge, drill pipe, drill pipe, etc., can solve the problems of unreliable clamping, inconsistent drill pipe center, increased drilling rig vibration, etc. Adjustable, clamping and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

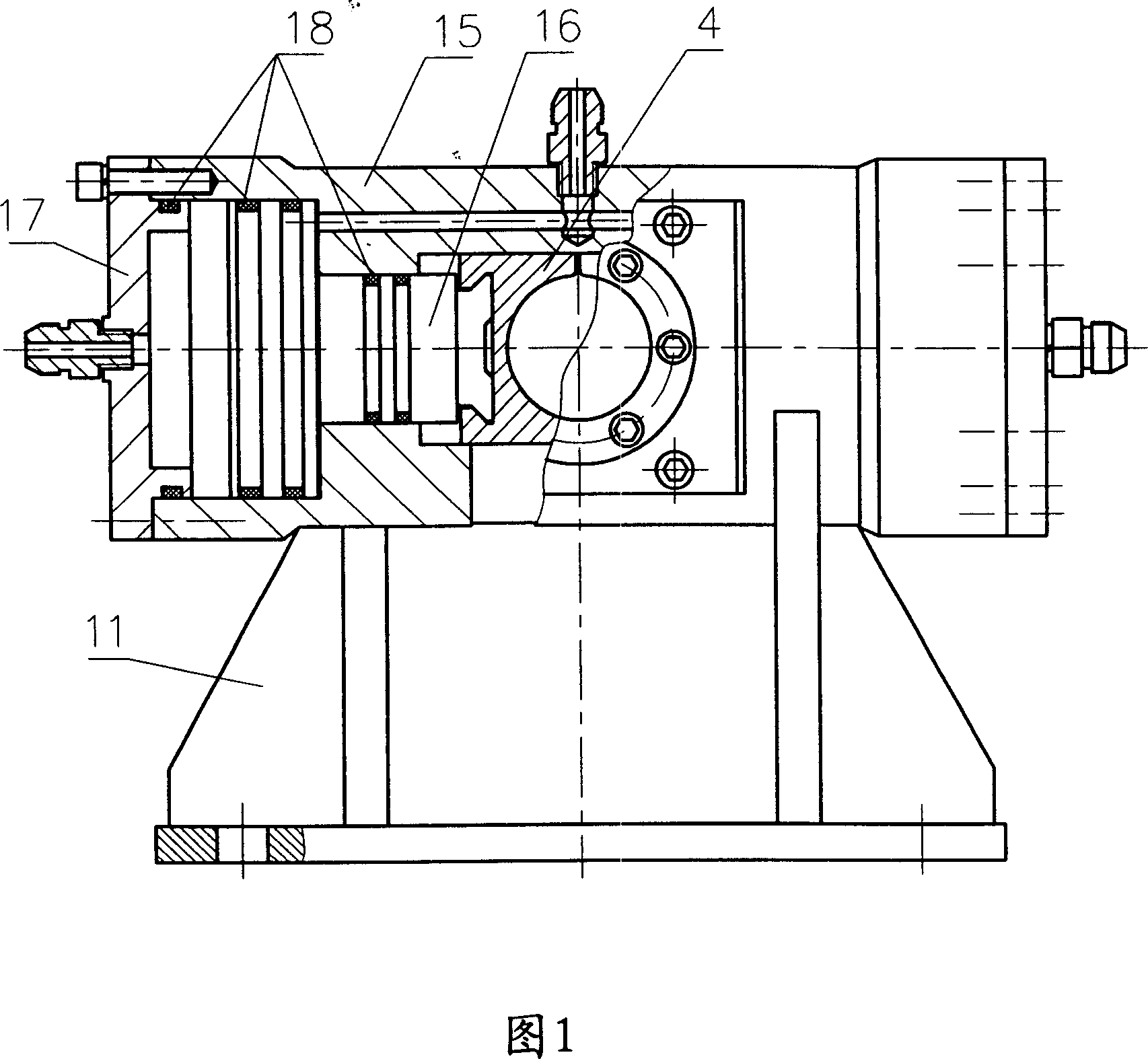

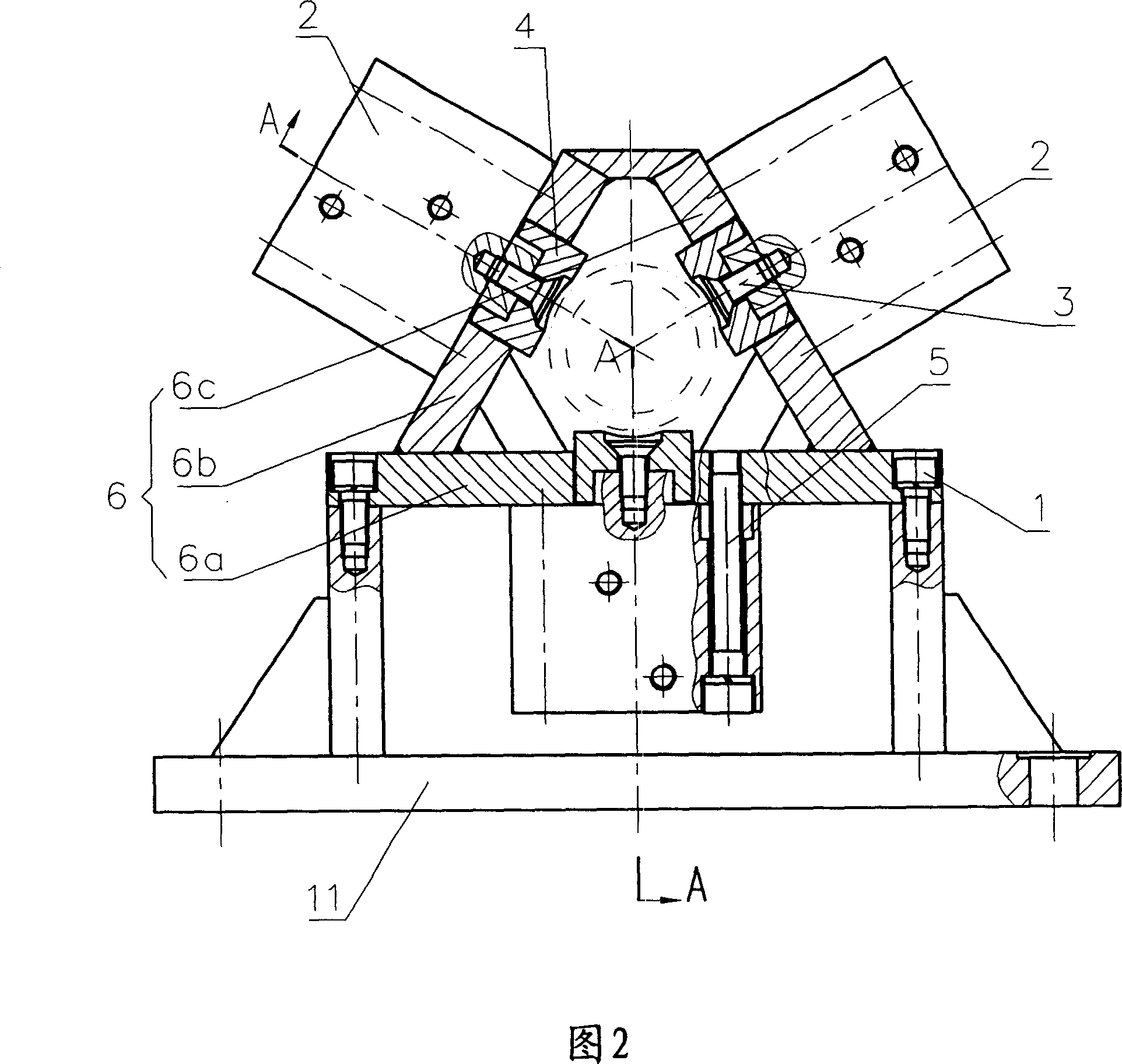

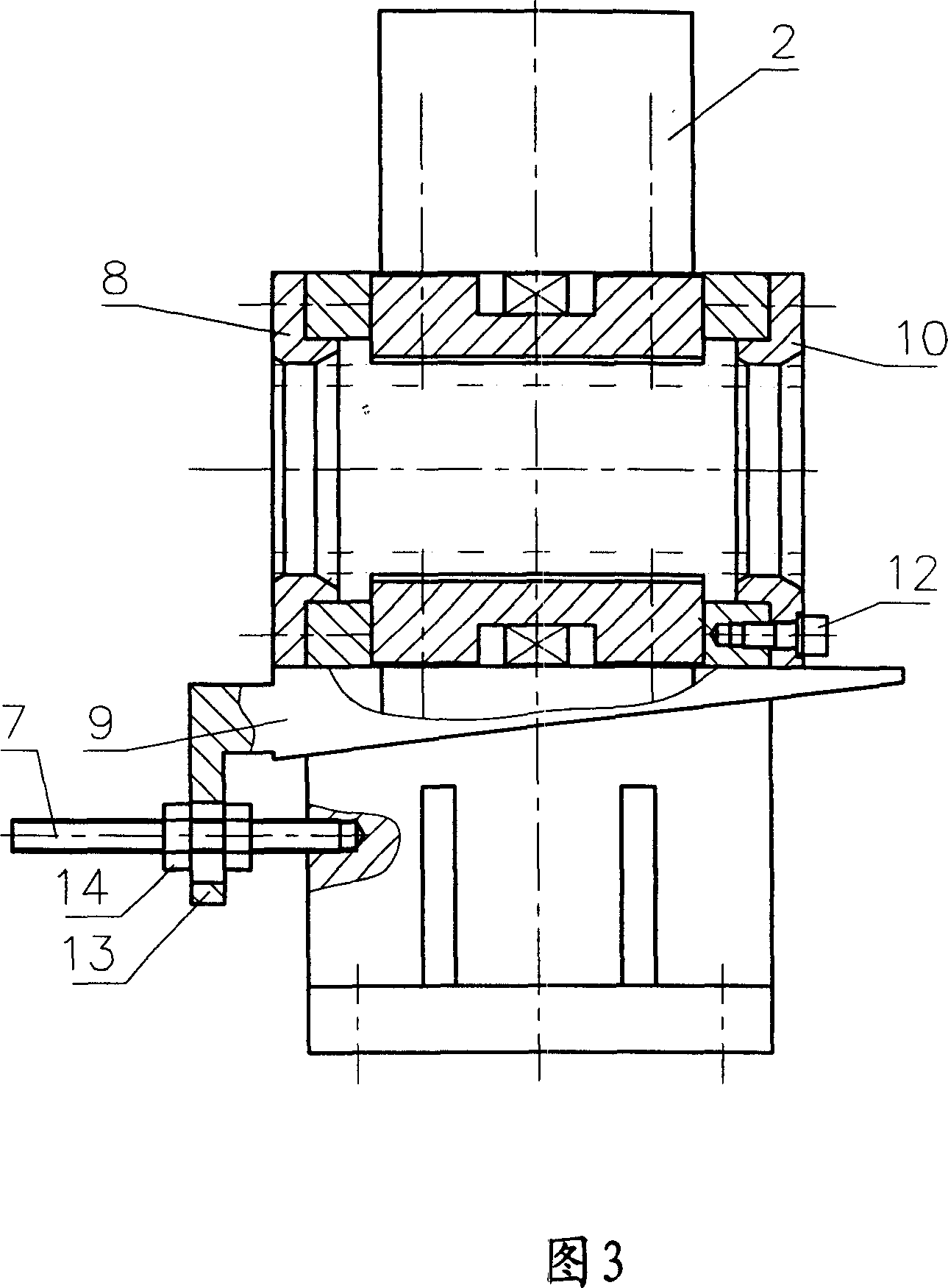

[0015] Such as figure 2 , image 3 As shown, the hydraulic clamper for the gas pumping and discharging drilling rig of the present invention is composed of a base 11, a support 6, slips 4 and a hydraulic cylinder 2. The support 6 has a bottom plate 6a and two side plates 6b, 6c, and the two side plates 6b and 6c are welded and fixed on the bottom plate 6a with the same inclination angle, the cross section of the bracket 6 is generally an equilateral triangle, the bottom plate 6a of the bracket 6 is installed on the base 11 through the bolt 1, the bottom plate 6a and the two side plates 6b, 6c are respectively A hydraulic cylinder 2 is installed with a bolt 5, and the piston rod of each hydraulic cylinder 2 is correspondingly connected with a slip 4, and the three slips 4 are evenly distributed around the circumference, and the geometric centers of the clamping parts of the three slips 4 coincide.

[0016] image 3 Show that between the base 11 and the support 6, a wedge blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com