Automatic control device for gas pressure

An automatic control device and gas pressure technology, which is applied in the direction of fluid pressure control, electric fluid pressure control, non-electric variable control, etc., can solve the problem of excessive raw gas that is difficult to dredge and collect, smoke and dust pollution, smoke and fire from the top of the furnace, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

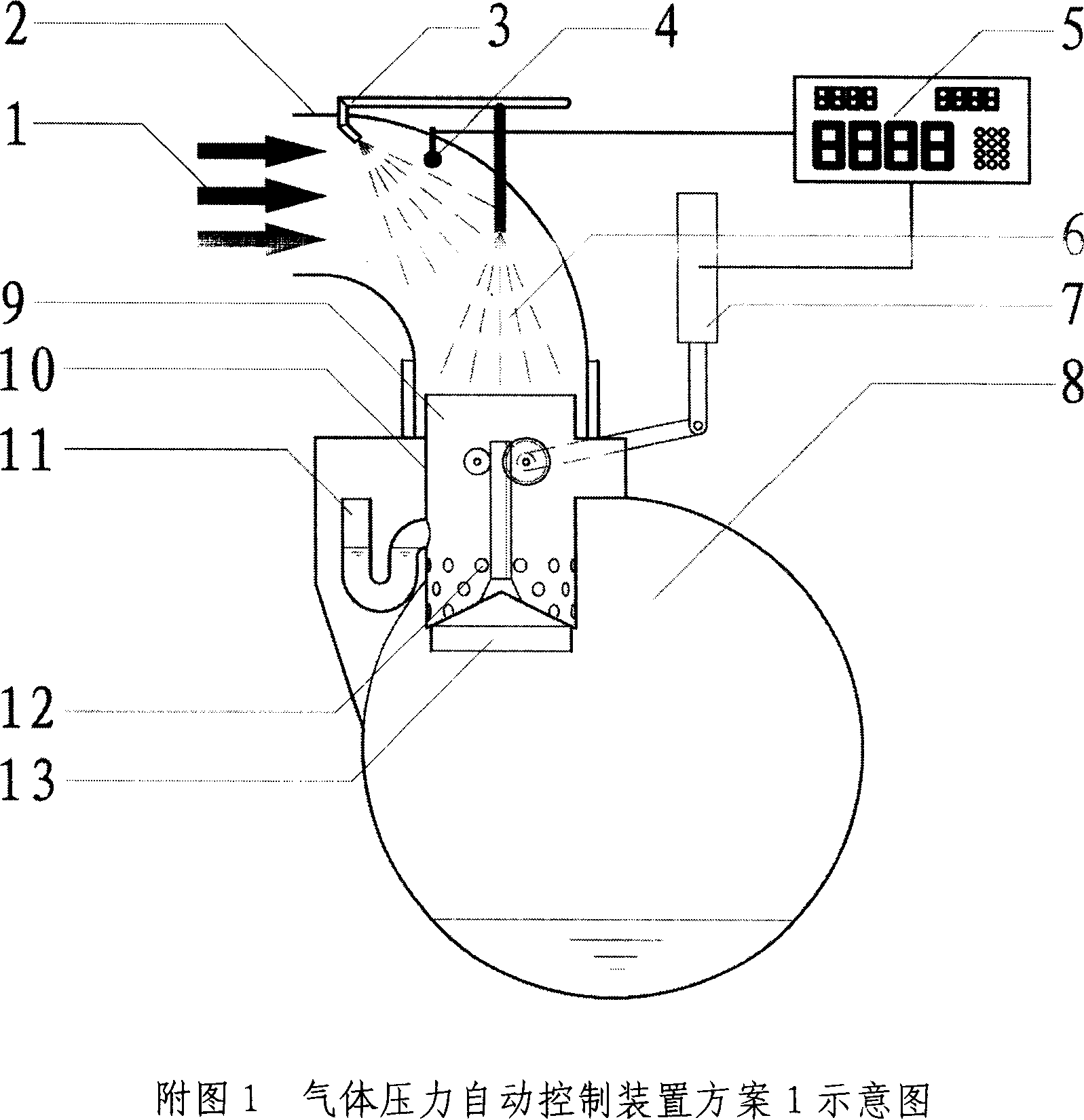

[0014] plan 1:

[0015] With reference to accompanying drawing 1, scheme 1 is made of pressure sensor 4, automatic controller 5, operating device 7, gas flow regulator 9. The gas 1 enters the gas flow regulator 9 through the intake pipe 2 , and enters the exhaust pipe 8 through the air guide hole 12 on the casing 10 of the gas flow regulator 9 . The liquid 6 enters the casing 10 of the gas flow regulator 9 from the pipeline 3 and flows out through the air guide hole 12 on the casing 10 or the bypass liquid-sealed pipe 11 on the casing 10 . The pressure sensor 4 collects the pressure data in the intake pipe 2 online and transmits the data to the automatic controller 5. After the automatic controller 5 processes the pressure data, it issues an action command to the action device 7, and the action device 7 drives the valve core 13 up and down. The action adjusts the position of the spool 13 in the casing 10 . As the position of the spool 13 changes, the number and area of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com