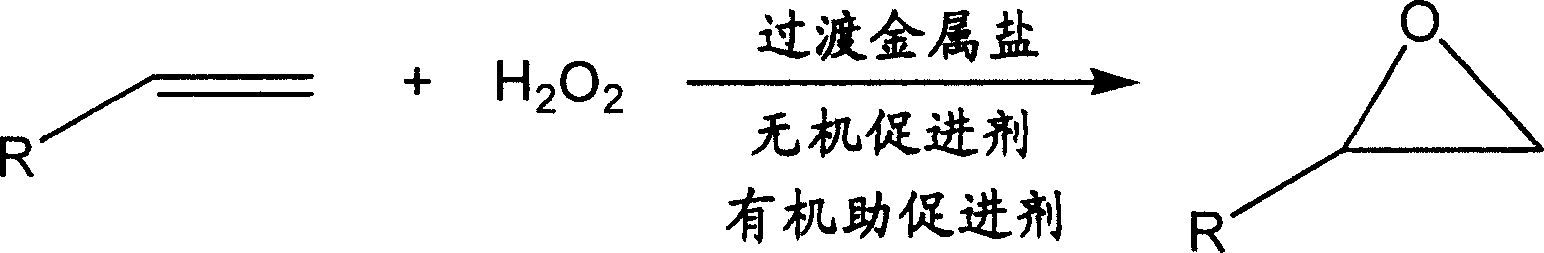

Improved catalytic process for the preparation of epoxides from alkenes

A technology for epoxides and alkenes, applied in organic chemistry and other directions, which can solve the problems of poor utilization efficiency of oxygen atoms, difficult possibilities, and low value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] To styrene (0.1mol), dodecane (0.01mol), urea (2.08mol), sodium bicarbonate (0.03mol) and magnesium sulfate (0.0001mol) in a mechanically stirred solution of 50.0ml of water at 20 ° C 30% aqueous hydrogen peroxide (0.22 mol) was added dropwise over a period of 4 h. After 4.5 h the organic layer of the reaction mixture was separated by a separatory funnel. The aqueous layer was extracted with 4 x 20 mL ether. The combined organic layers were distilled to give styrene oxide. The conversion to epoxide was 99% and the selectivity was 94%.

Embodiment 2

[0044]To a mechanically stirred solution of styrene (0.1mol), dodecane (0.01mol), urea (2.08mol), sodium bicarbonate (0.03mol) in 50.0ml of water was added dropwise 30% of Aqueous hydrogen peroxide (0.22 mol). After 5 h the organic layer of the reaction mixture was separated by a separatory funnel. The aqueous layer was extracted with 4 x 20 mL ether. The combined organic layers were distilled to give styrene oxide. The conversion to epoxide was 99% with a selectivity of 95%.

Embodiment 3

[0046] To styrene (1.0mol), dodecane (0.1mol), urea (20.8mol), sodium bicarbonate (0.3mol) and magnesium sulfate (0.001mol) in a mechanically stirred solution of 500ml of water at 20 ° C for 5h 50% aqueous hydrogen peroxide (2.2 mol) was added dropwise over time. After 5 h the organic layer of the reaction mixture was separated by a separatory funnel. The aqueous layer was extracted with 4 x 20 mL ether. The combined organic layers were distilled to give styrene oxide. The conversion to epoxide was 99% with a selectivity of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com