Magnetic rheopectic solution fan clutch

A magneto-rheological fluid and clutch technology, which is applied in fluid clutches, clutches, machines/engines, etc., can solve the problems that cannot be applied to small and small spaces, large spaces, etc., and achieve compact structure, promote heat exchange, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

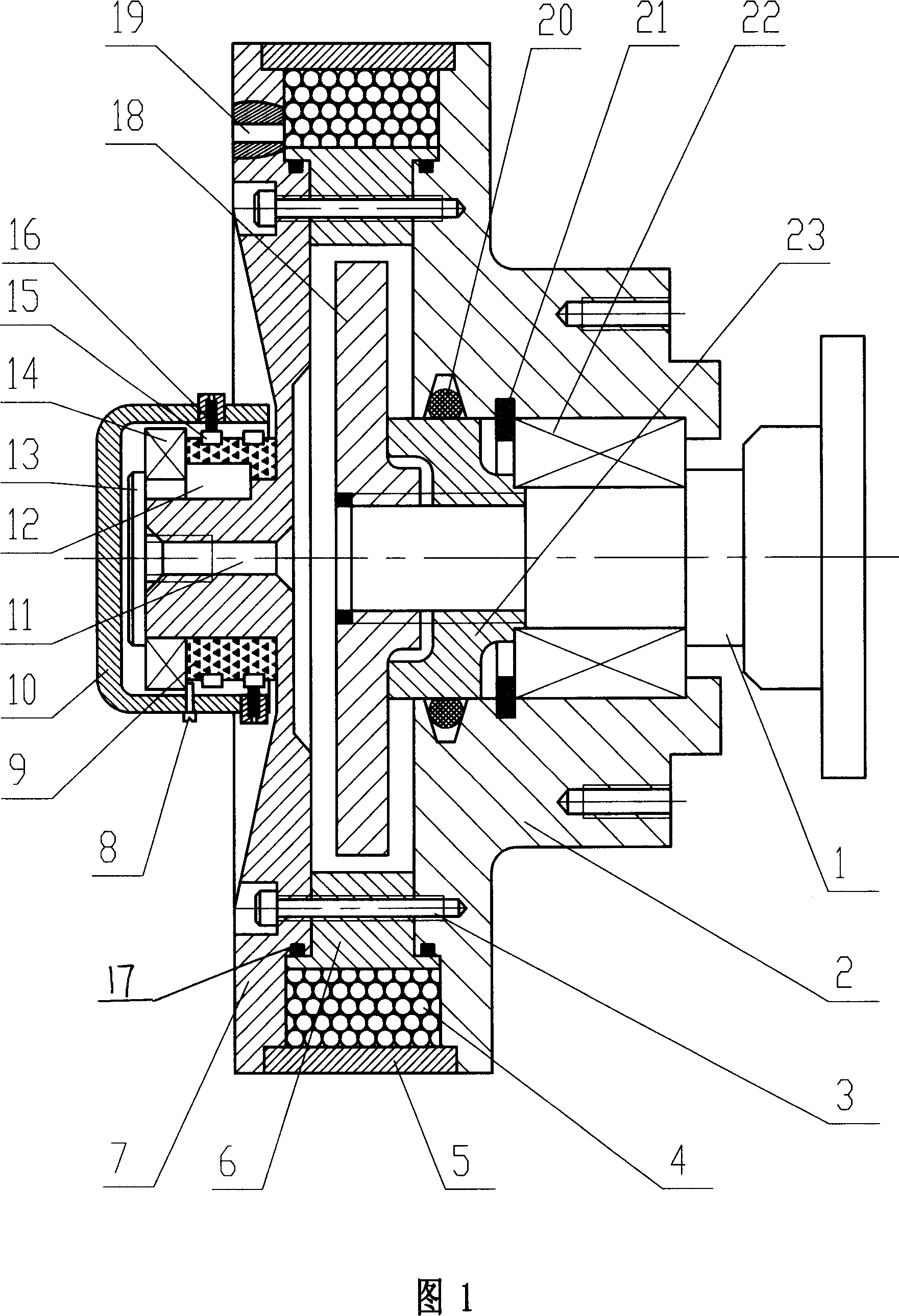

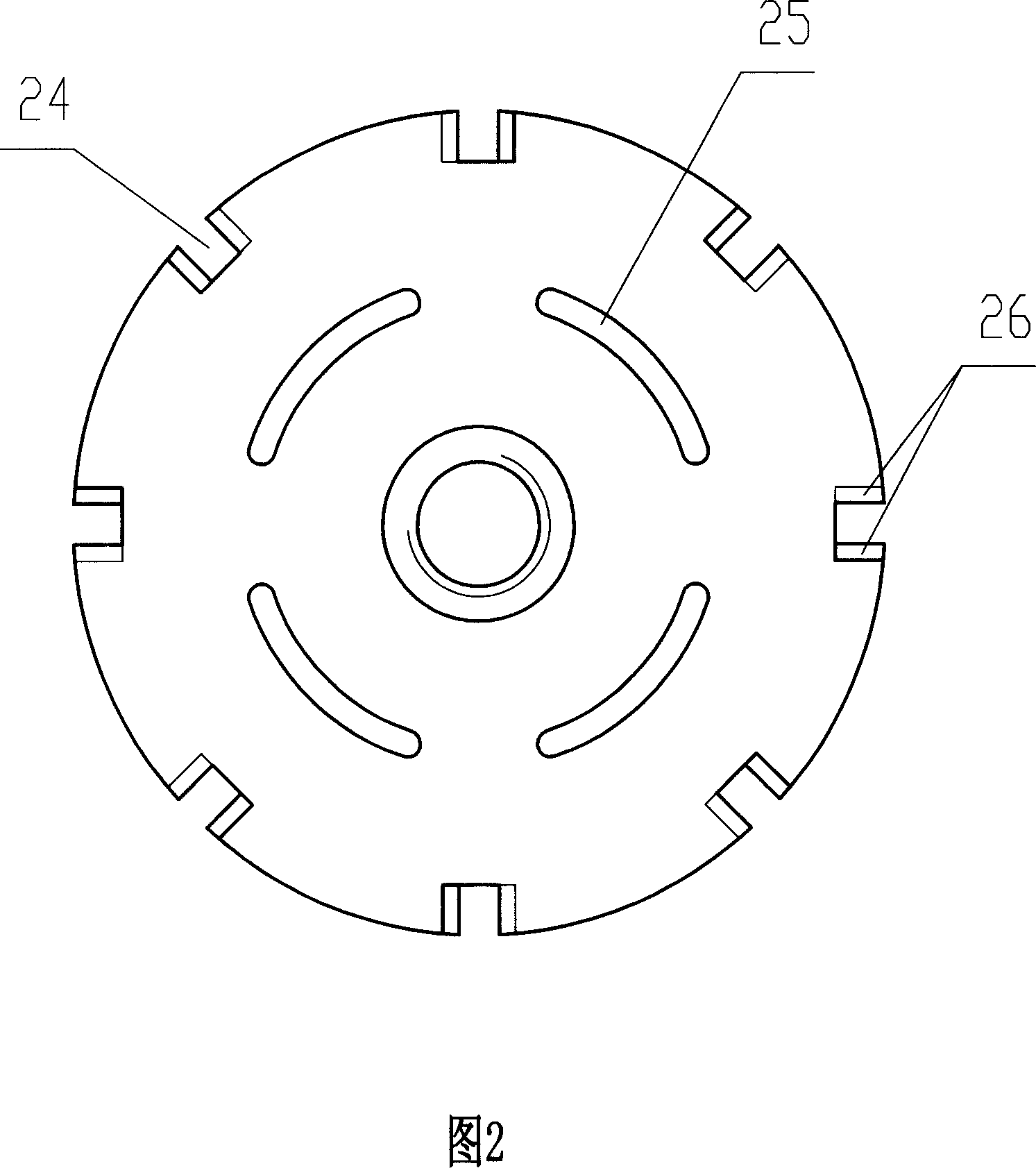

[0024] As can be seen from Fig. 1 and Fig. 2, the present invention has following structure:

[0025] On the power transmission shaft 1 of the present invention, bearing 22, bearing retaining ring 21, axle sleeve 23 and active piece 18 are installed successively, wherein axle sleeve 23 and active piece 18 are to be connected on the transmission shaft 1 by screw thread, and the rotation direction of its screw thread and The rotation direction of the driving shaft 1 is opposite; a clutch housing is installed outside the bearing 22, and the clutch housing as a whole is used as a passive part, and its housing is divided into a front housing 7 and a rear housing 2, and the rear housing 2 is installed on the bearing 22 , an O-ring seal 20 is arranged on the outside of the shaft sleeve 23, and the O-ring seal 20 is embedded in the clutch rear housing 2; the clutch front housing 7 is fixedly connected with the clutch rear housing 2 through the connecting bolt 3 as a whole. Between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com