Method and device for measuring initial and final set time for non-damage type concrete

A technology of final setting time and concrete, applied in the direction of material inspection products, etc., can solve the problems of inaccurate penetration force, inability to test online for a long time, large experimental workload, etc., to eliminate artificial reading errors, suitable for on-site performance testing, and environmental requirements. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

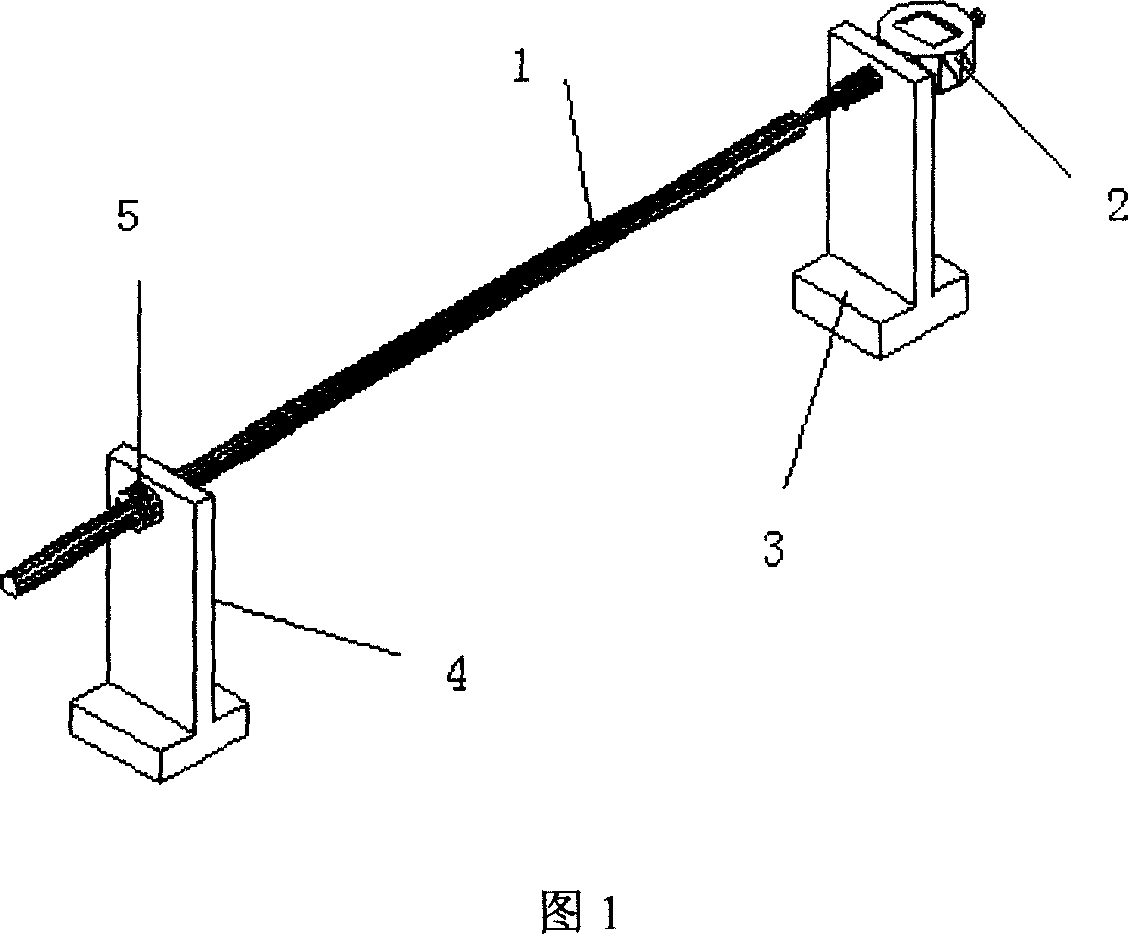

[0032] As shown in Figure 1, the device for testing the initial and final setting time of non-destructive concrete of the present invention includes a transfer rod 1, a left partition 4, a right partition 3, a dial indicator 2 and a clamping screw 5, and the transmission One end of the rod 1 passes through the left partition 4 and is fixed by the clamping screw 5, and the other end is in contact with the tapered end of the dial indicator passing through the right partition 3.

[0033] In the non-destructive device for testing the initial and final setting time of concrete according to the present invention, the base of each partition is used to support the entire partition and ensure the stability of the entire device during pouring. The transfer rod is made of high carbon steel with a thermal expansion coefficient similar to that of the concrete material, and is cylindrical in shape with a diameter of 8mm.

[0034] In the non-destructive device for testing the initial and fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com