Testing mark for detecting projection object lens image errors, mask and detection method

A difference detection and marking technology, which is applied in the field of lithography machine projection object image quality detection, to achieve the effect of increasing the speed, improving the measurement accuracy of coma aberration, and improving the detection accuracy of aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The test mark, mask and aberration detection method of the present invention will be further described in detail below.

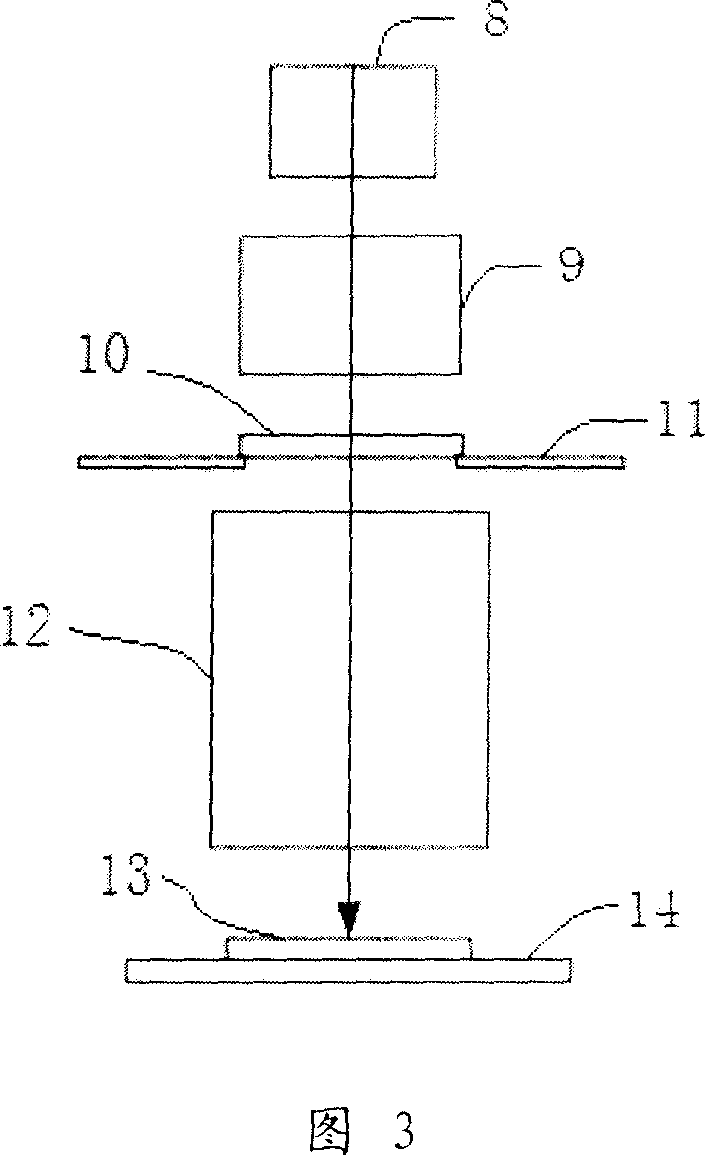

[0040] The present invention mainly utilizes the relative imaging position offset caused by the aberration under the interference condition of 0th order and +1st order or 0th order and -1st order diffracted light, and solves the third-order coma, fifth-order coma, Seventh-order coma, three-wave aberration, spherical aberration and astigmatism.

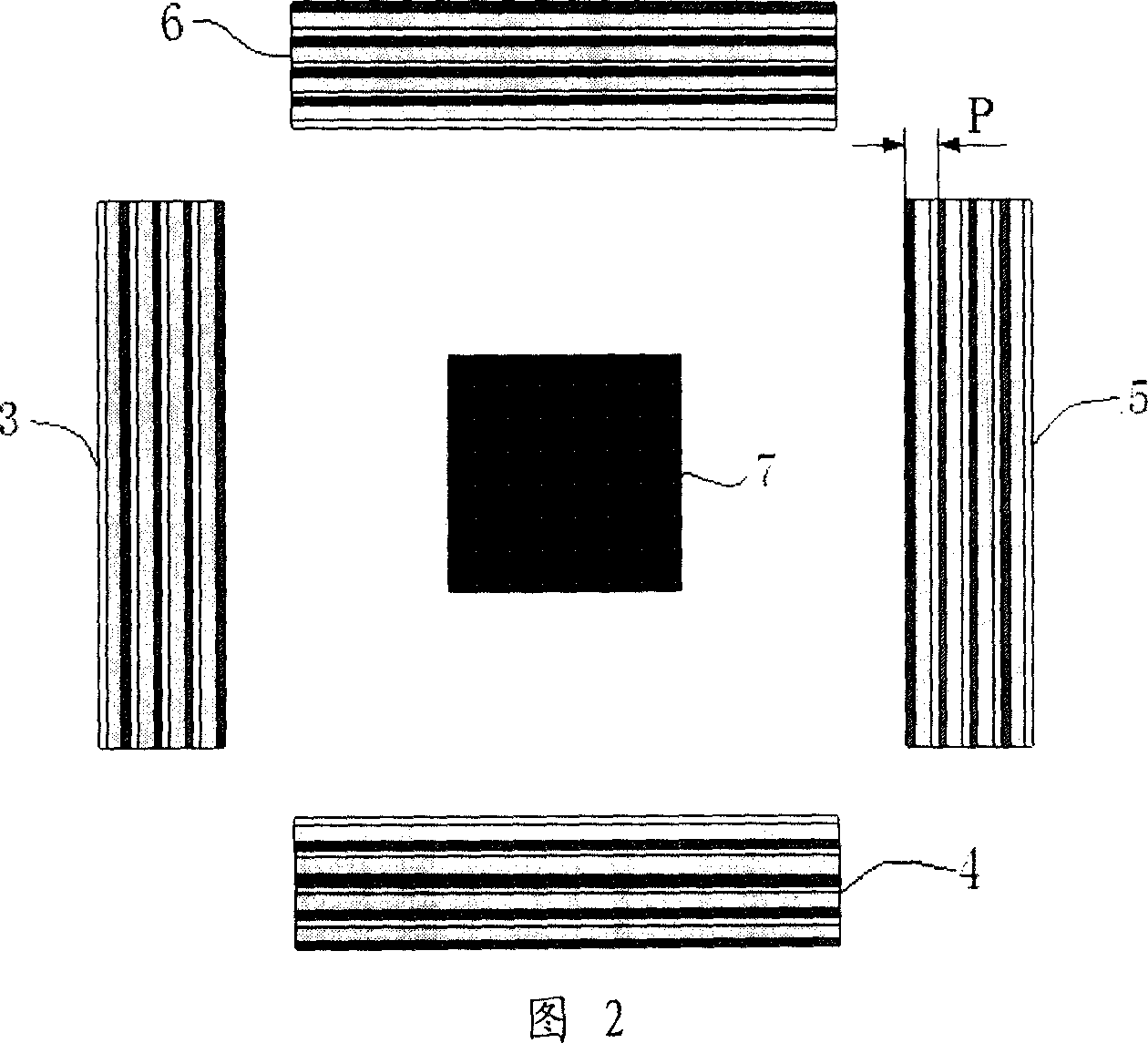

[0041] As shown in FIG. 2 , the test marks used in the present invention include a square inner mark 7 and four sets of outer marks 3 , 4 , 5 , 6 . The periods of the four groups of external marks 3, 4, 5, and 6 are the same, and the difference between two adjacent groups of external marks is 90°. In the figure, external mark 4 can be obtained by rotating external mark 3 clockwise by 90°; external mark 5 can be obtained by rotating external mark 4 clockwise by 90°; external mark 6 can be obtained by rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com