System for supplying very low voltage electrical energy for an electrical traction vehicle comprising an onboard store of energy

A power supply, ultra-low voltage technology, applied in the field of ultra-low voltage power supply system, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

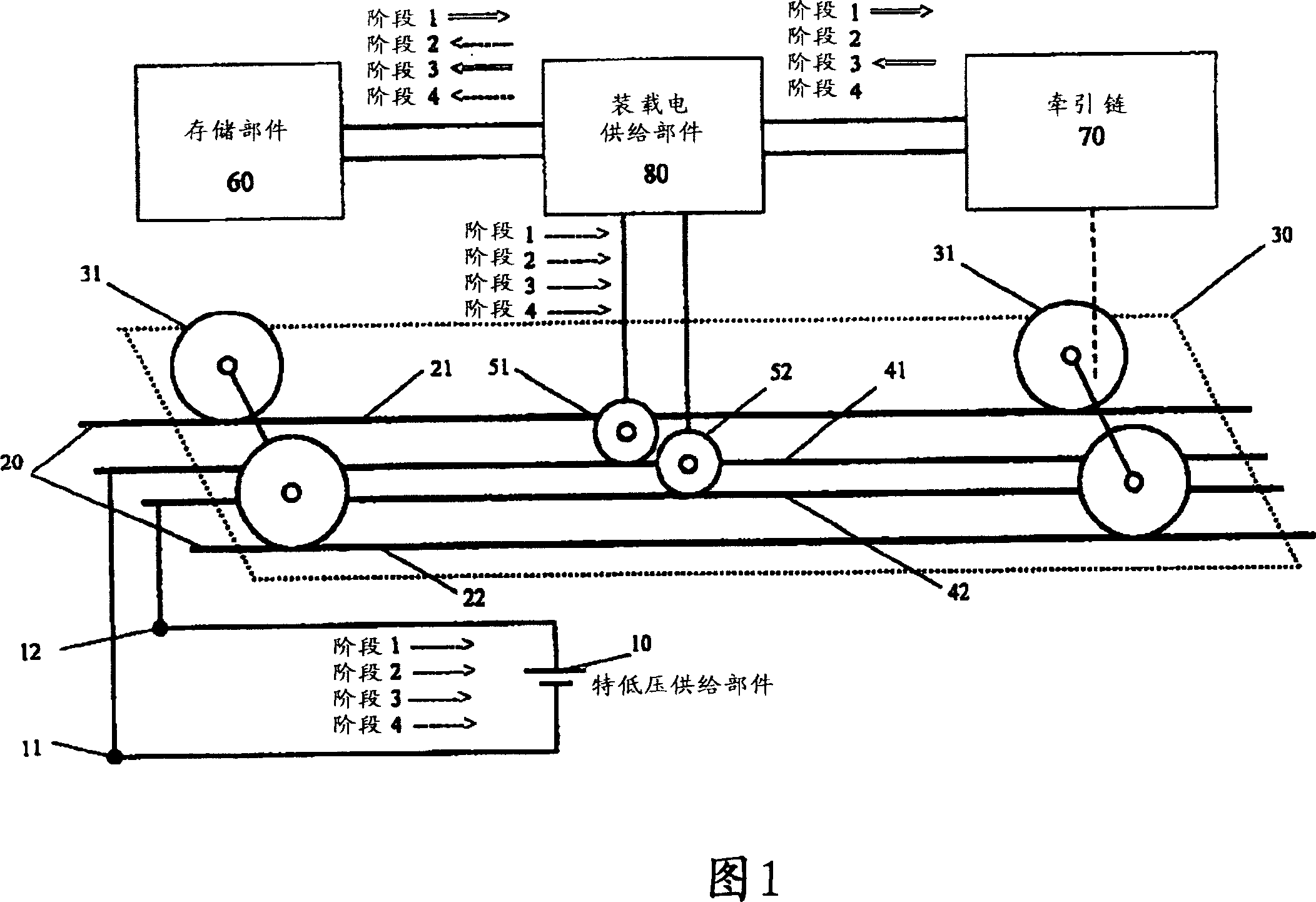

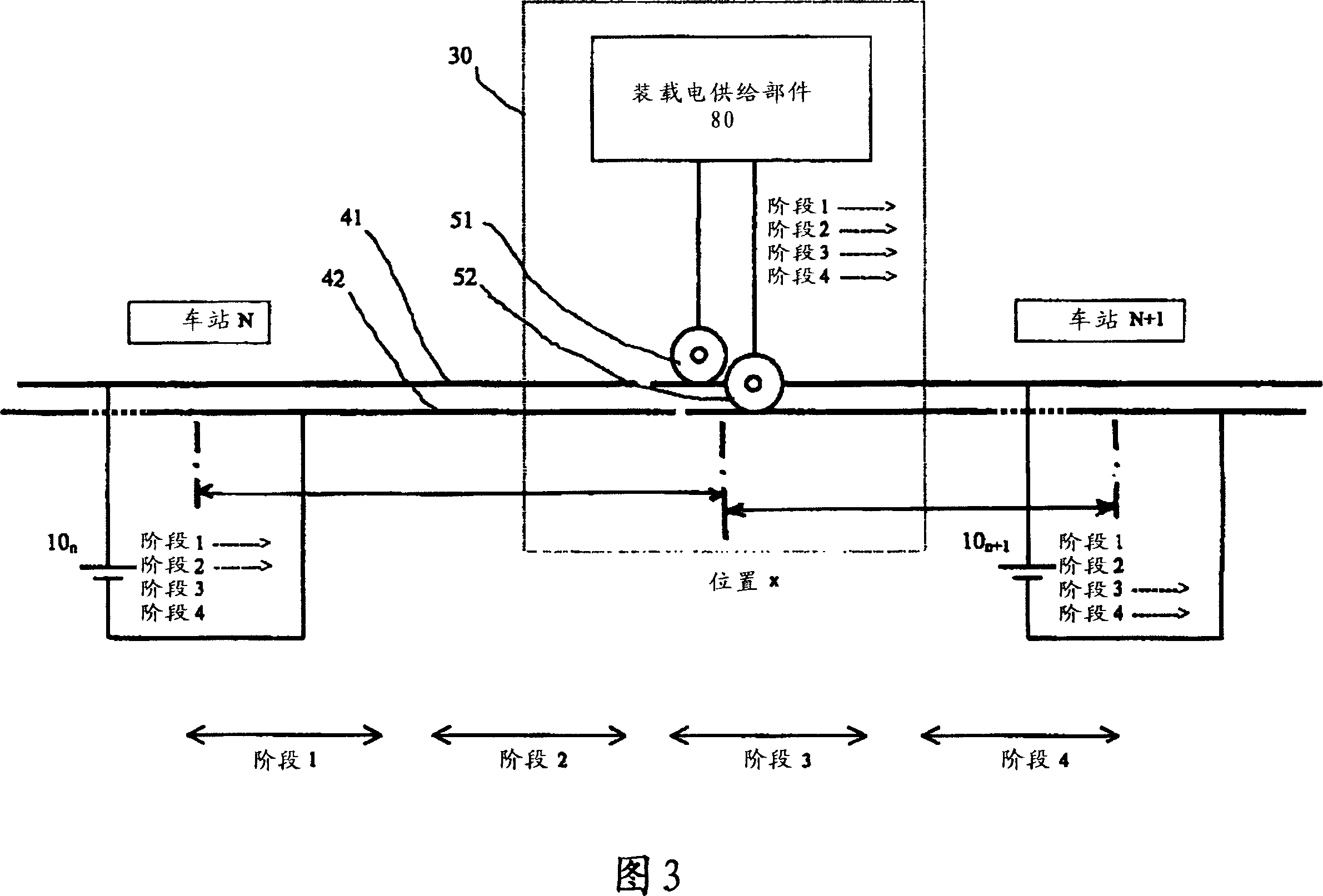

[0055] [55] Figure 1 shows a configuration of the supply system according to the invention, called a four-track configuration, for a railway vehicle of the tram type. The system comprises an extra-low voltage power supply part 10 installed next to at least one railroad track 20 having two running rails 21, 22 on which the vehicles move.

[0056] [56] Between the running rails, there are two power supply rails 41, 42, which are parallel to each other and parallel to the running rails, wherein the first power supply rail 41 is connected to a connection of the power supply part. The second power supply rail 42 is connected to the other terminal 12 of the power supply component.

[0057] [57] A railway vehicle 30 is run on the railway track, the railway vehicle includes four runners 31 connected to the vehicle. A first electric energy collecting part 51 and a second electric energy collecting part 52 are installed in the railway vehicle, and these collecting parts are placed in m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com