Multicomponent compound drip washing liquid, repair method and its apparatus

A kind of eluent and multi-component technology, which is applied in the direction of inorganic/elemental cleaning composition, restoration of polluted soil, non-ionic surface active compounds, etc. It can solve the problems of high content of petroleum pollutants and the inability to achieve soil harmlessness, etc. , to achieve the effect of short cycle, easy operation and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

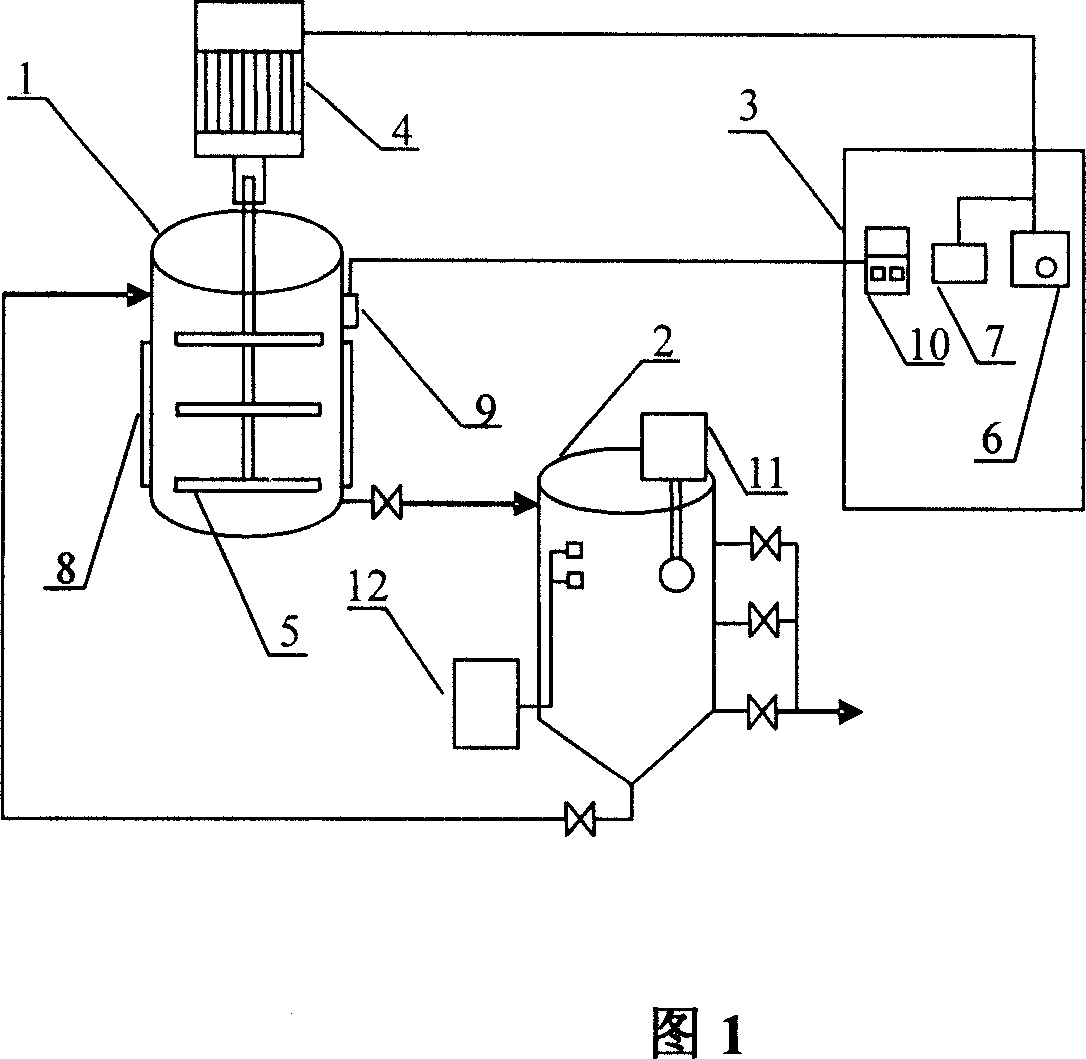

[0021] Prepare heavy oil-contaminated soil with an oil concentration of 20,000mg / Kg, put it in an oven and dry it at 50°C for three days to simulate the aged heavy-oil-contaminated soil (some studies have shown that putting oil-contaminated soil in an oven at 50°C, After more than three days, most of the compounds with carbon atoms below 16 in petroleum components volatilized Urum K, Pekdemir T, Copur M.Surfactants treatment of crude oil contaminated soils.Journal of Colloid and Interface Science, 2004, 276( 2): 456~464). After aging, the measured value of the actual oil concentration in the heavy oil-polluted soil is 12176.72 mg / Kg. The specific steps of the gradient leaching method are as follows: First, weigh 100 g of the aged heavy oil-contaminated soil and add it to the leaching reactor (1), and then use a 10:1 (eluent: polluted soil, ml / g) liquid-solid than adding 1000ml of multi-component compound eluent configured by sodium dodecylbenzenesulfonate, Triton X-100, sodiu...

Embodiment 2

[0025]Prepare heavy oil-contaminated soil with an oil concentration of 200,000 mg / Kg, put it in an oven and bake it at 50°C for three days. After aging, the measured value of the actual oil concentration of the heavy oil-contaminated soil is 189,227.32 mg / Kg. The specific steps of the gradient leaching method are as follows: first, weigh 100 g of the aged heavy oil-contaminated soil and add it to the leaching reactor (1), and then press the liquid-solid concentration of 10:1 (eluent: polluted soil, ml / g) Add 1000ml of multi-component compound eluent prepared by sodium dodecylbenzenesulfonate, Triton X-100, sodium carbonate, sodium tripolyphosphate, sodium silicate, anhydrous sodium sulfate and water. The distribution ratio of each component in the lotion is shown in Table 1; then, the washing temperature is set at 60°C through the temperature control meter (10) in the automatic control cabinet (3), and the frequency conversion governor (6) and timer ( 7) Stir for 30 minutes un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com