Liquid-cooled radiating system

A heat dissipation system and liquid cooling technology, applied in the field of heat transfer, can solve the problems of reducing heat dissipation efficiency, large thermal resistance, and small thermal conductivity of pure liquid, and achieve the effect of improving heat transfer coefficient, heat dissipation efficiency, and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

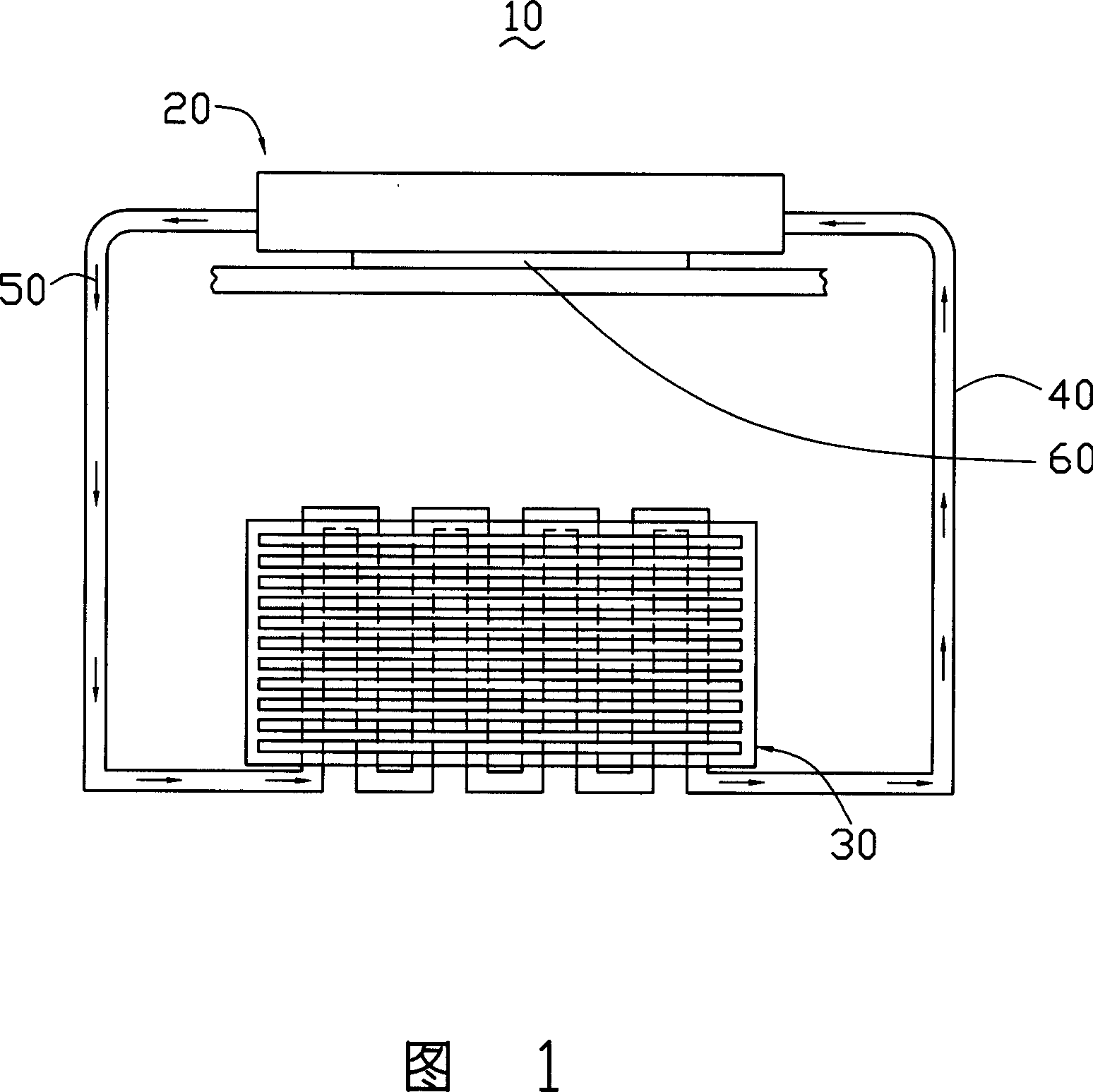

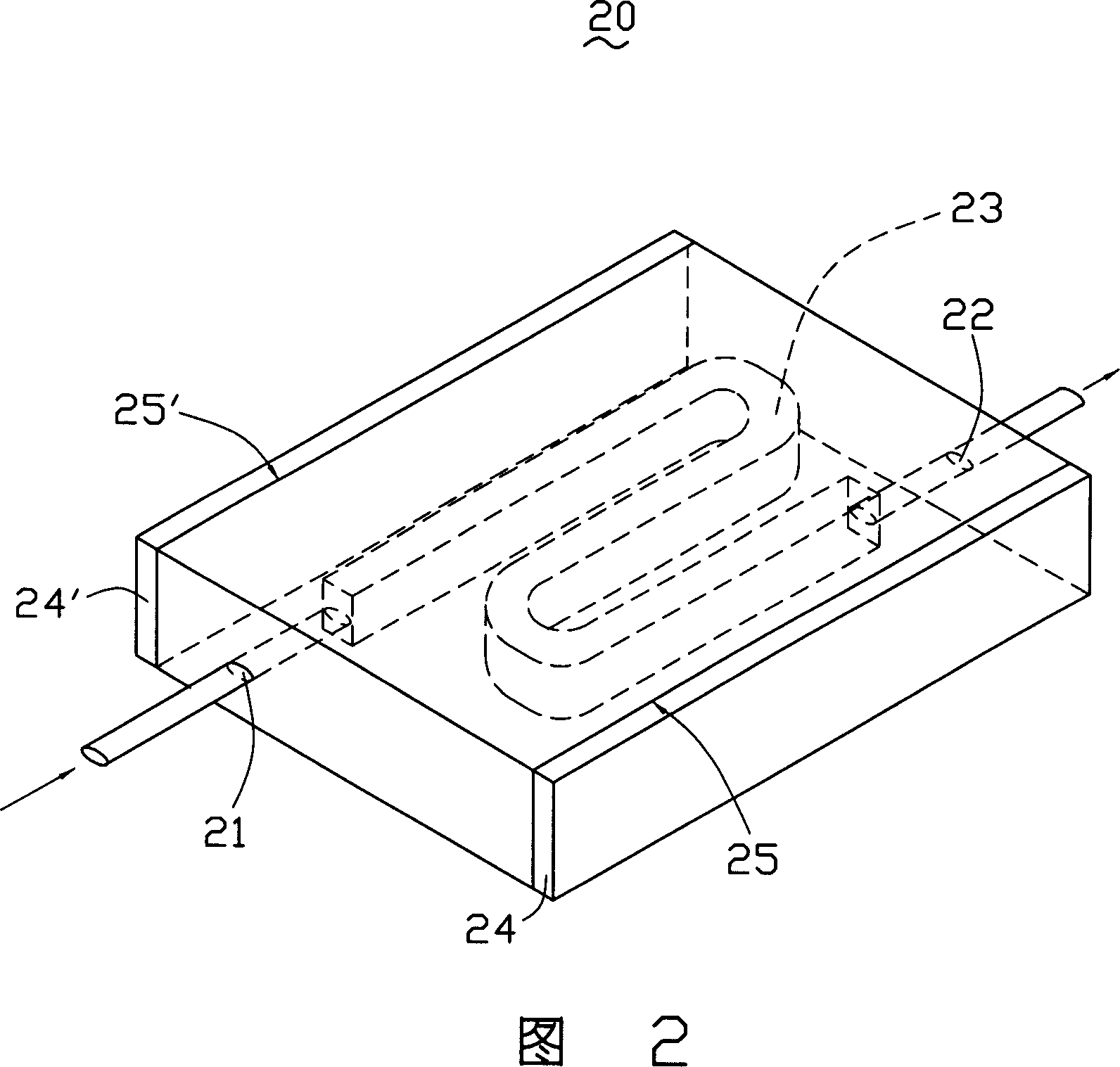

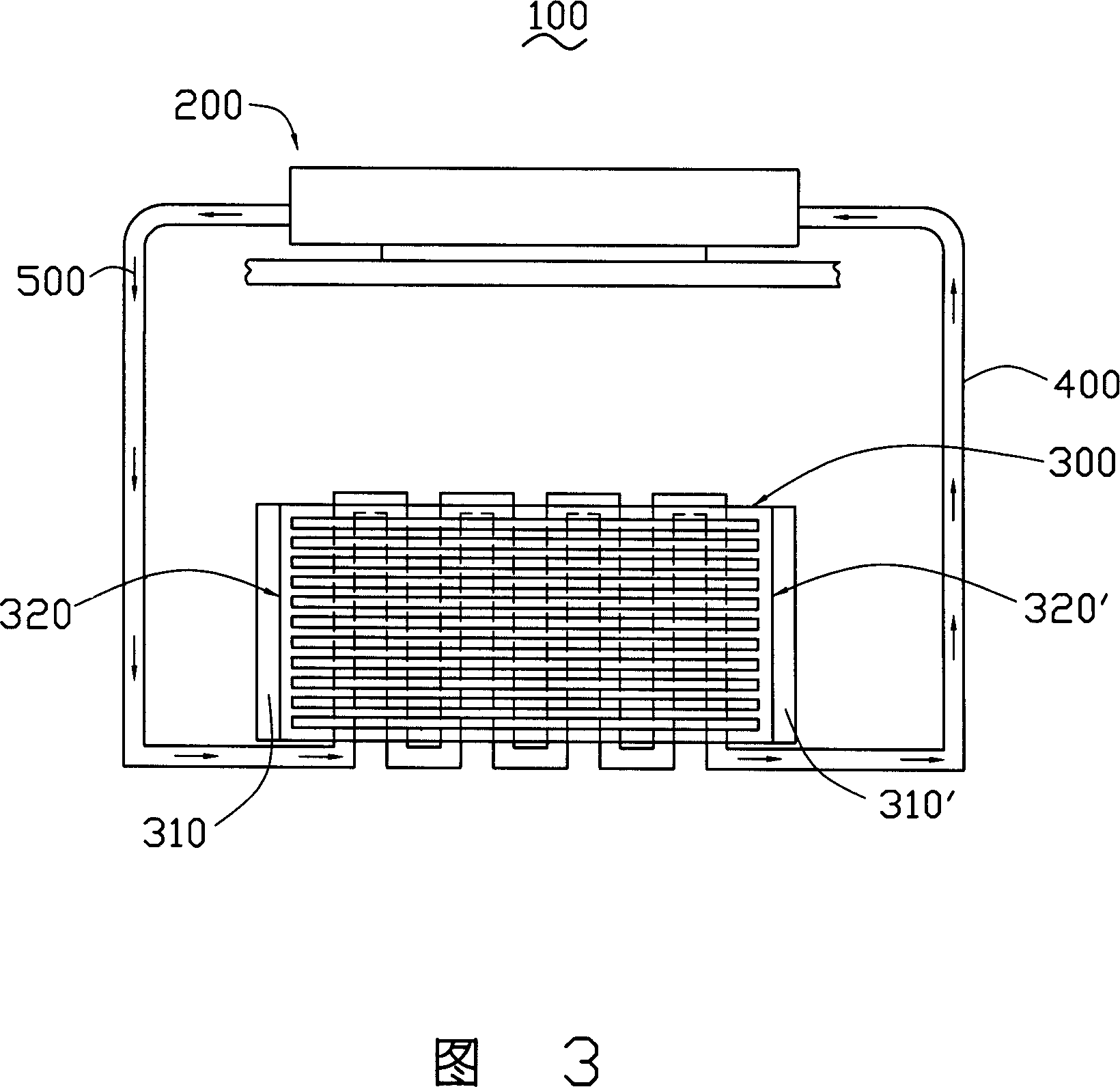

[0013] Referring to FIG. 1 , the liquid-cooled heat dissipation system 10 provided in the first embodiment of the present invention includes: a heat absorption unit 20 ; a heat dissipation unit 30 ; a connecting conduit connecting the heat absorption unit 20 and the heat dissipation unit 30 40; and the working fluid 50 flowing in the heat absorption unit 20 and the connecting conduit 40, wherein the working fluid 50 includes a liquid medium and magnetic powder dispersed in the liquid medium, and the connecting conduit 40 passes through In the heat dissipation unit 30 .

[0014] The liquid medium in the working fluid 50 includes one or more of water, alcohols and ketones, and the alcohols can be methanol, ethanol, propanol, n-butanol, n-pentanol, n-hexanol, A mixture of one or more of n-heptanol, n-octanol and ethylene glycol, the ketones can be acetone, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com