Laser cutting method and apparatus

A technology of cutting device and cutting method, which is applied in the direction of welding equipment, laser welding equipment, metal processing equipment, etc., can solve problems such as inappropriateness, and achieve the effects of saving man-hours, improving production efficiency, and saving return time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

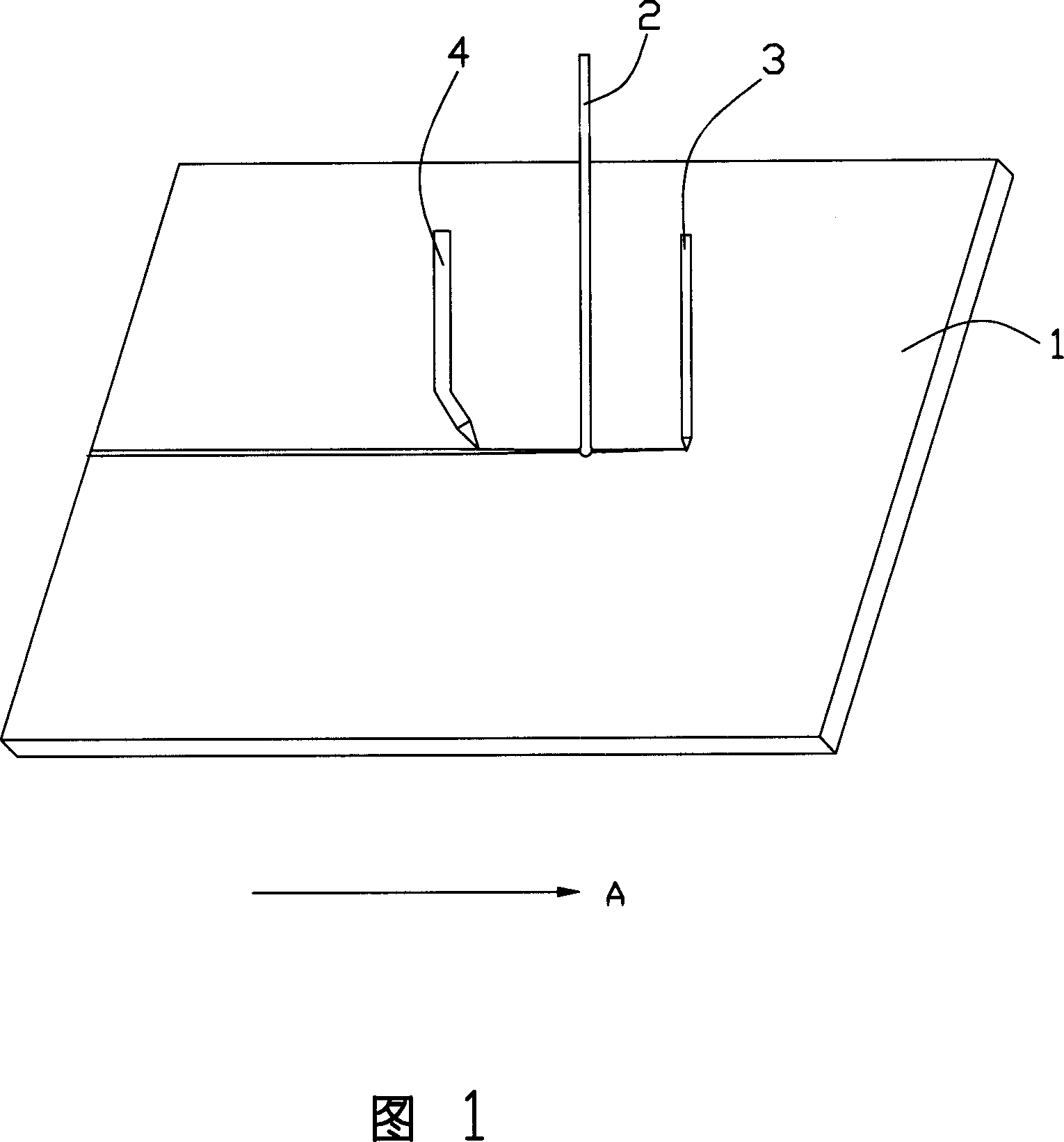

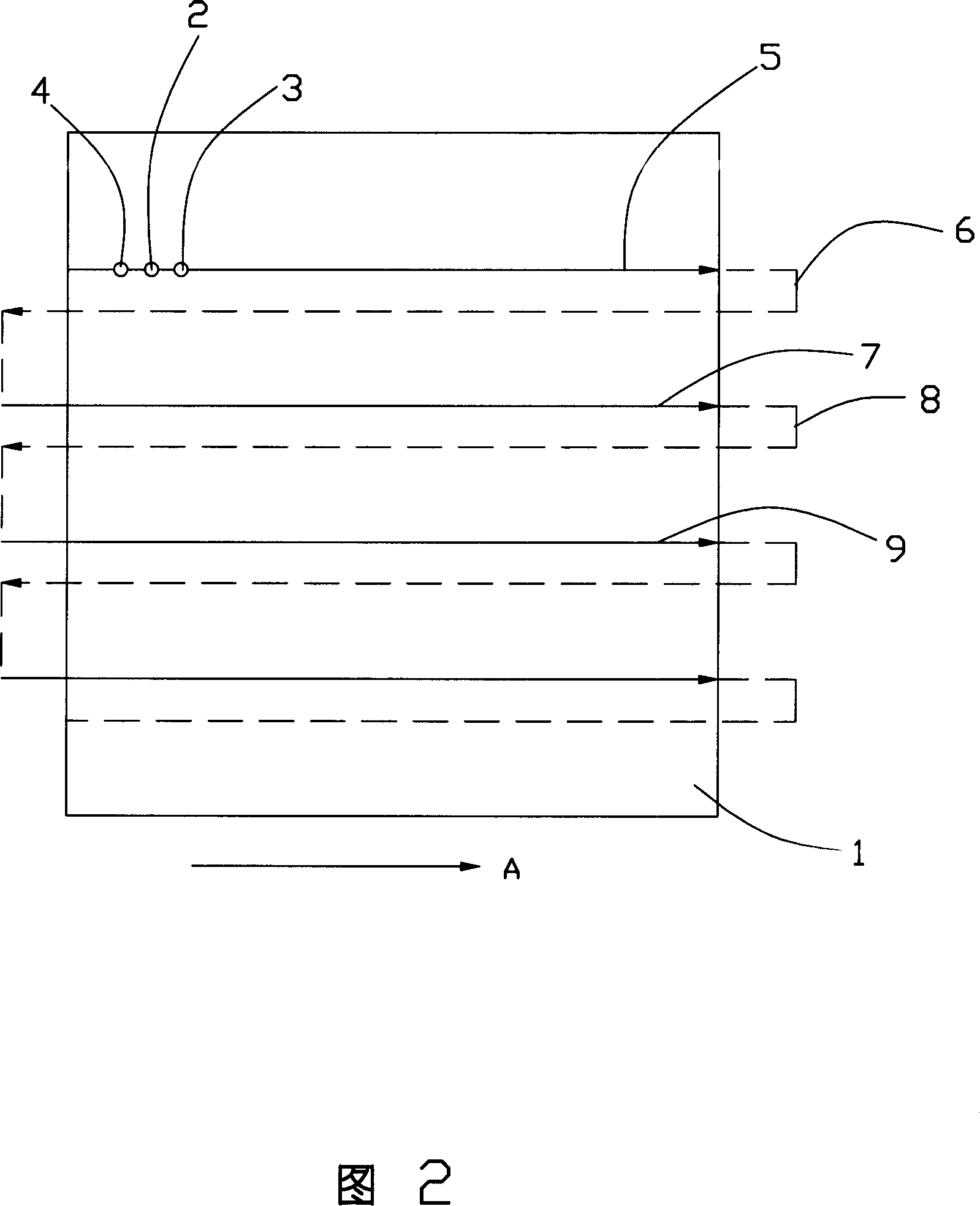

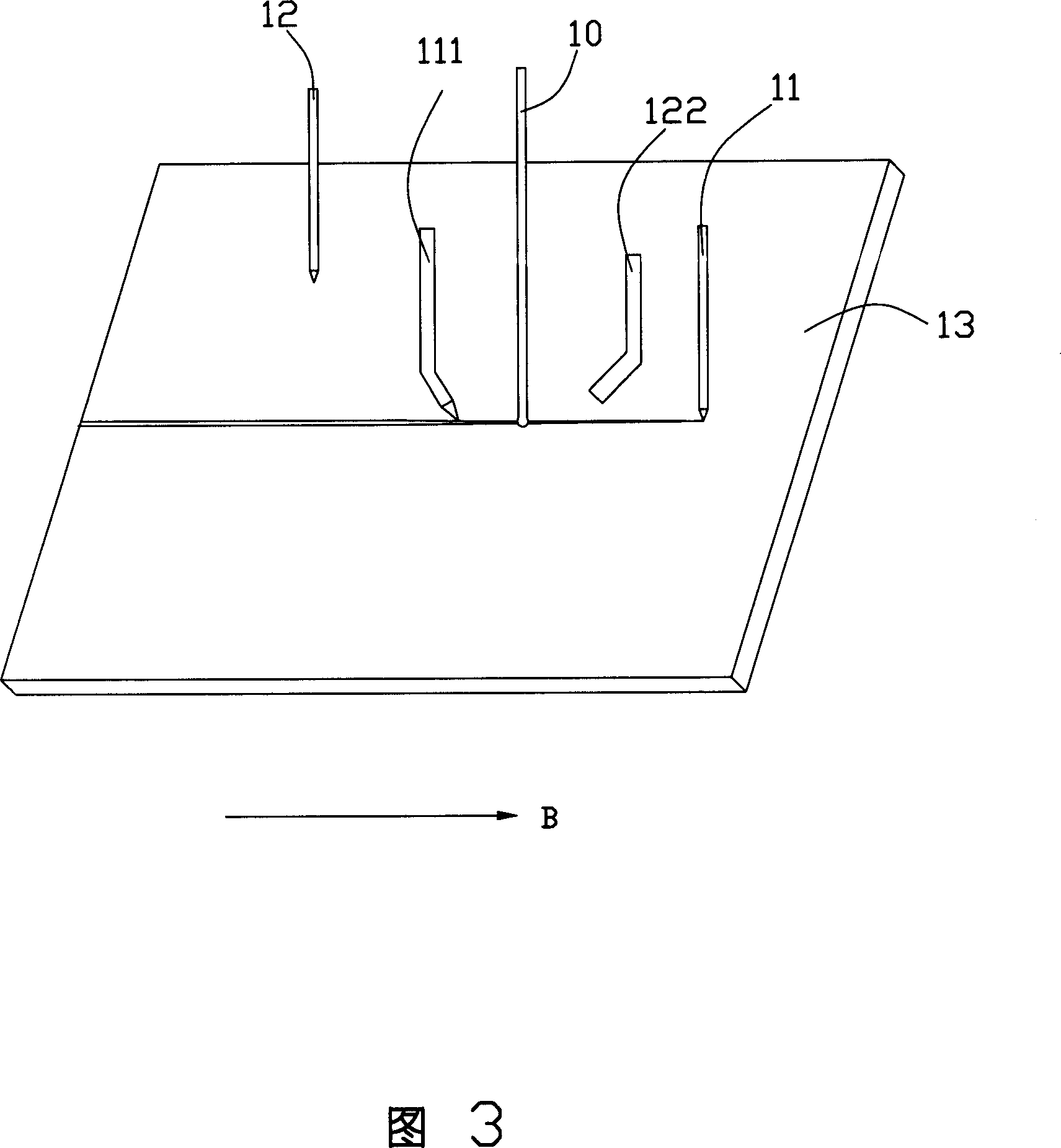

[0020] Referring to FIGS. 3 to 5, the laser cutting unit for cutting glass substrate 13 of the present invention includes a laser system 10, a first marking tool 11, a first cooling system 111, a second marking tool 12 and a second marking tool 12. cooling system 122 .

[0021] In the laser cutting unit of the present invention, the first scribing tool 11 and the second scribing tool 12 can be any tools that can generate predetermined cracks on the surface of the glass substrate, such as laser beams, diamond knives, and cutter wheels. The first cooling system 111 and the second cooling system 122 can be a single liquid, a mixture of a single gas and a single liquid, or a mixture of more than one gas and liquid, such as pure water, cooling oil, liquid nitrogen or liquid helium.

[0022] Compared with the existing laser cutting technology, the laser system 10 of the laser cutting unit of the present invention, the marking tool 11,12 and the cooling system 111,122 do not involve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com