Image-forming apparatus, process cartridge and image-forming method

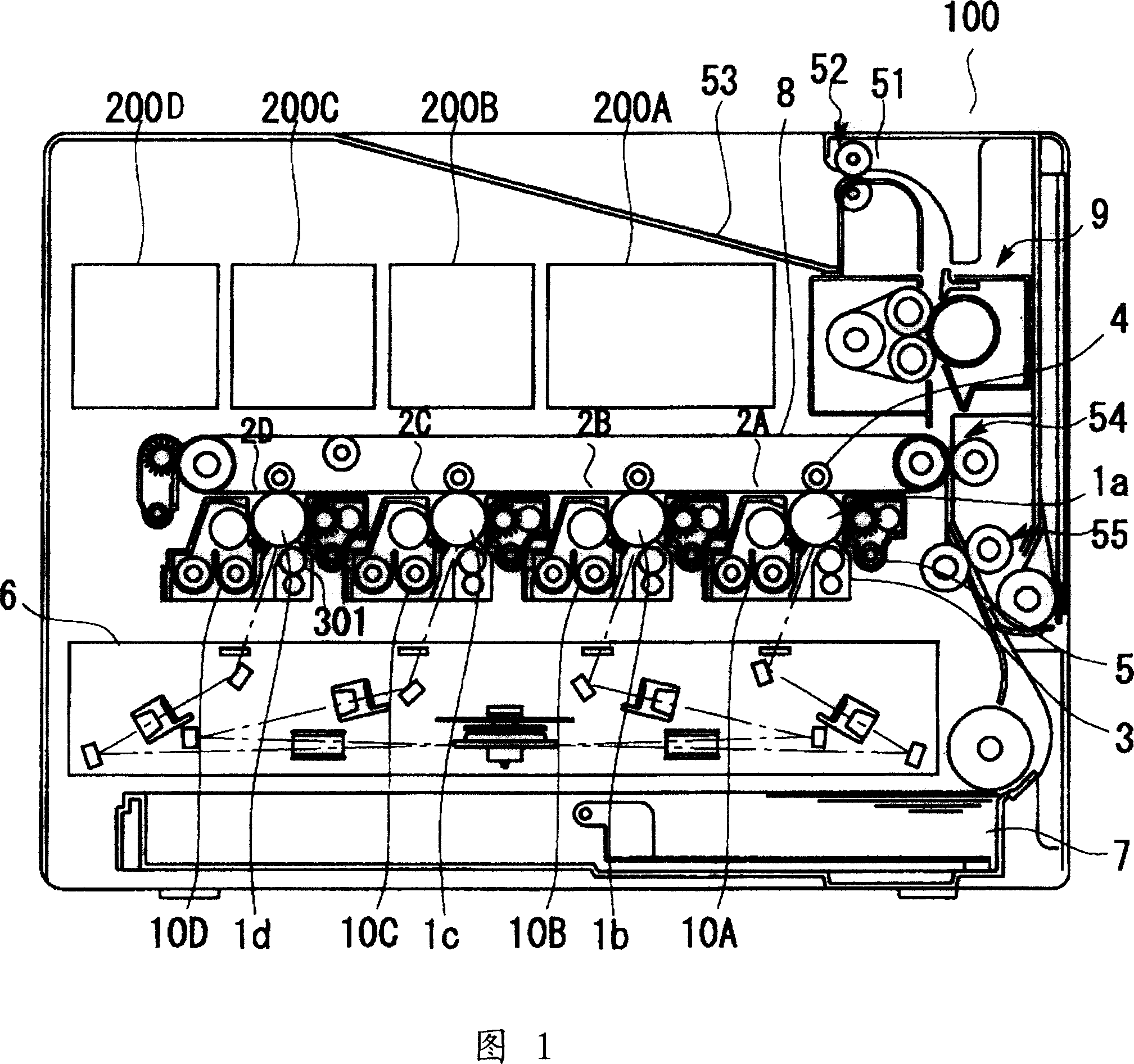

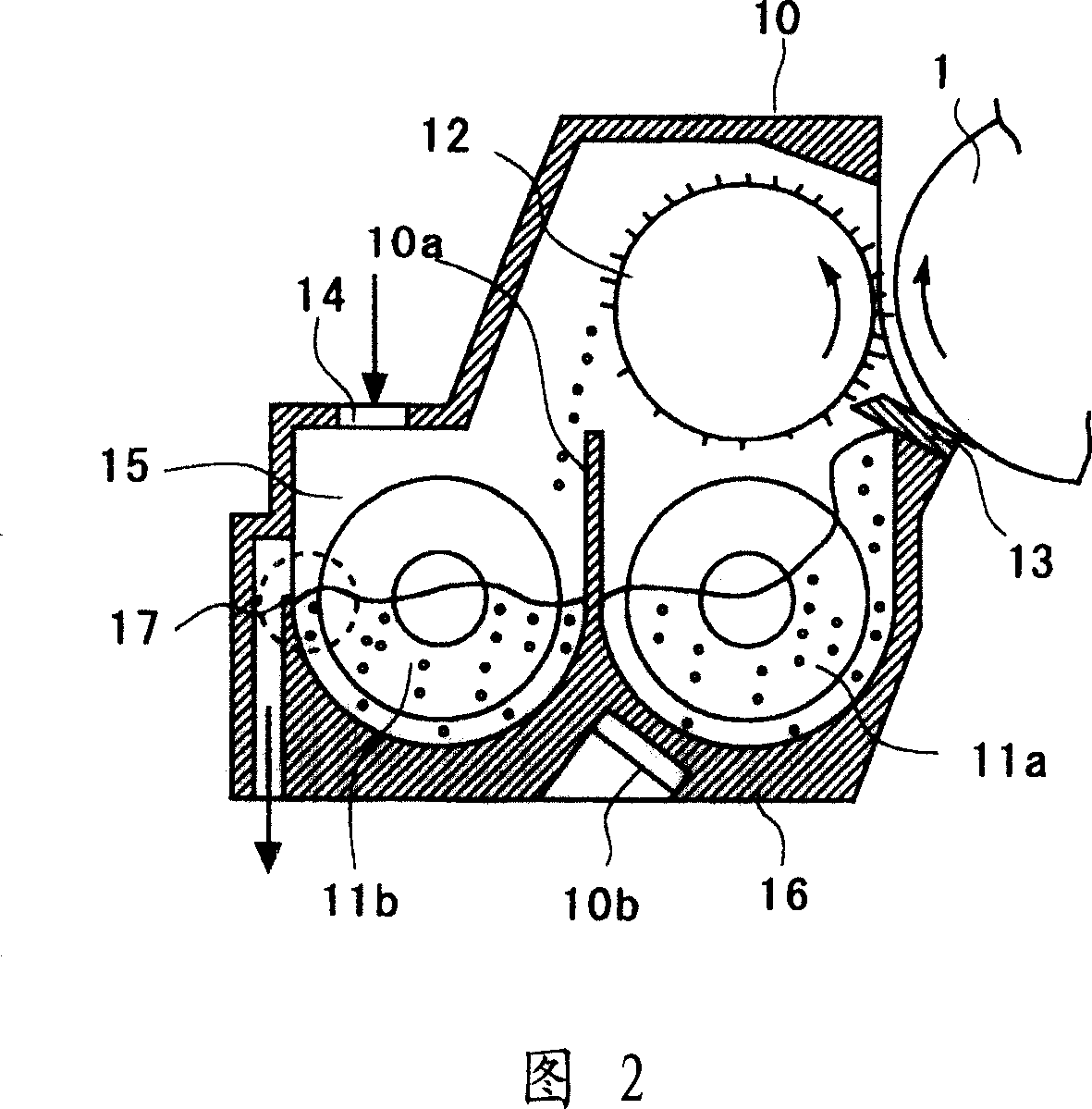

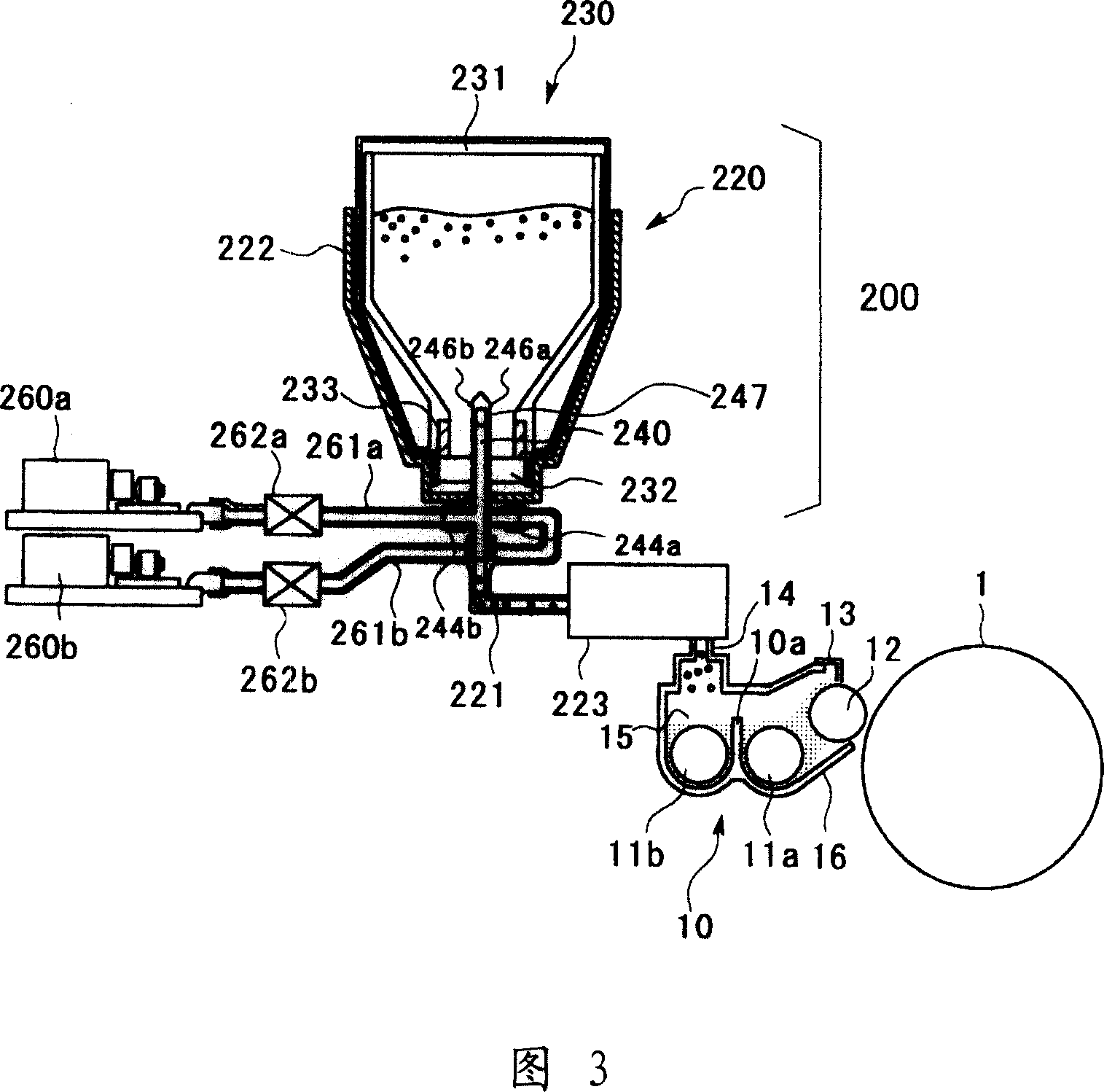

一种成像装置、图像的技术,应用在成像领域,能够解决不能获得调色剂稳定带电量、控制复杂、供应性能差异大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0274] The present invention is further described in detail with reference to the following examples, which are not intended to limit the scope of the present invention. All parts and percentages (%) are by mass unless otherwise indicated.

[0275] In Examples and Comparative Examples, "percentage of voids of toner", "degree of fluidity of developer", "mass average particle diameter and number average particle diameter of toner", "toner The average circularity", "charged amount", "mass average particle size of the carrier", and "thickness of the carrier coating film".

[0276]

[0277] (1) The measurement method of the true density of the toner:

[0278] Prepare a stainless steel cylinder with an inner diameter of 10 mm and a length of about 5 cm, a disc (A) that can be inserted into the stainless steel cylinder in close contact with an outer diameter of about 10 mm and a height of 5 mm, and a disc (A) with an outer diameter of about 10 mm. mm and a height of about 8 cm fo...

preparation Embodiment 1

[0302] ~Synthesis of Organic Particle Emulsion~

[0303] In a reaction vessel equipped with a stirrer and a thermometer, 683 parts of water, 11 parts of sodium salt of methacrylate ethylene oxide adduct sulfate (ELEMINOL RS-30 manufactured by Sanyo Chemical Industries, Ltd.), 166 parts of methacrylic acid, 110 parts of butyl acrylate, and 1 part of ammonium persulfate were stirred at 3,800 rpm for 30 minutes to obtain a white emulsion. The emulsion was heated until the system temperature reached 75°C, and reacted for 3 hours. Furthermore, 30 parts of a 1% ammonium persulfate aqueous solution was added, and the mixture was aged at 75° C. for 5 hours to obtain a vinyl resin (methacrylic acid-butyl acrylate-methacrylic acid ethylene oxide adduct Copolymer of sodium salt of sulfuric acid ester), "fine particle dispersion 1". The volume average particle diameter of "fine particle dispersion 1" was measured by LA-920, and found to be 75 nm. A part of "fine particle dispersion 1" ...

preparation Embodiment 2

[0333] ~Preparation of "Low Molecular Polyester 2"~

[0334] 460g of polyoxypropylene (2.2)-2,2-bis(4-hydroxyphenyl)propane, 72g of ethylene glycol, 306g of terephthalic acid, 90g of 1,2,4-trimelellitic anhydride (trimellitic anhydride), and 1.2g of dibutyltin oxide was placed in a 2-liter four-necked glass flask equipped with a thermometer, a stainless steel stirrer, a falling film (falling-film) condenser and a nitrogen introduction tube, and passed through a mantle heater in a nitrogen atmosphere. The reaction was carried out by stirring at 190°C for 4 hours in a stream and then at 220°C.

[0335] The reaction was terminated when the glass transition point reached 130°C. The obtained resin had a number average molecular weight of 4,800, a weight average molecular weight of 17,700, a glass transition temperature (Tg) of 63° C., and an acid value of 5 mgKOH / g.

[0336] (Toner composition raw materials)

[0337] Binder resin: "low molecular weight polyester 1" 50 parts

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com