Centrifugal switch driver for single-phase inductive motor

A single-phase induction motor and centrifugal switch technology, applied in the direction of electric switches, circuits, electrical components, etc., can solve the problems of centrifugal weight noise, spring breakage, longer assembly time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

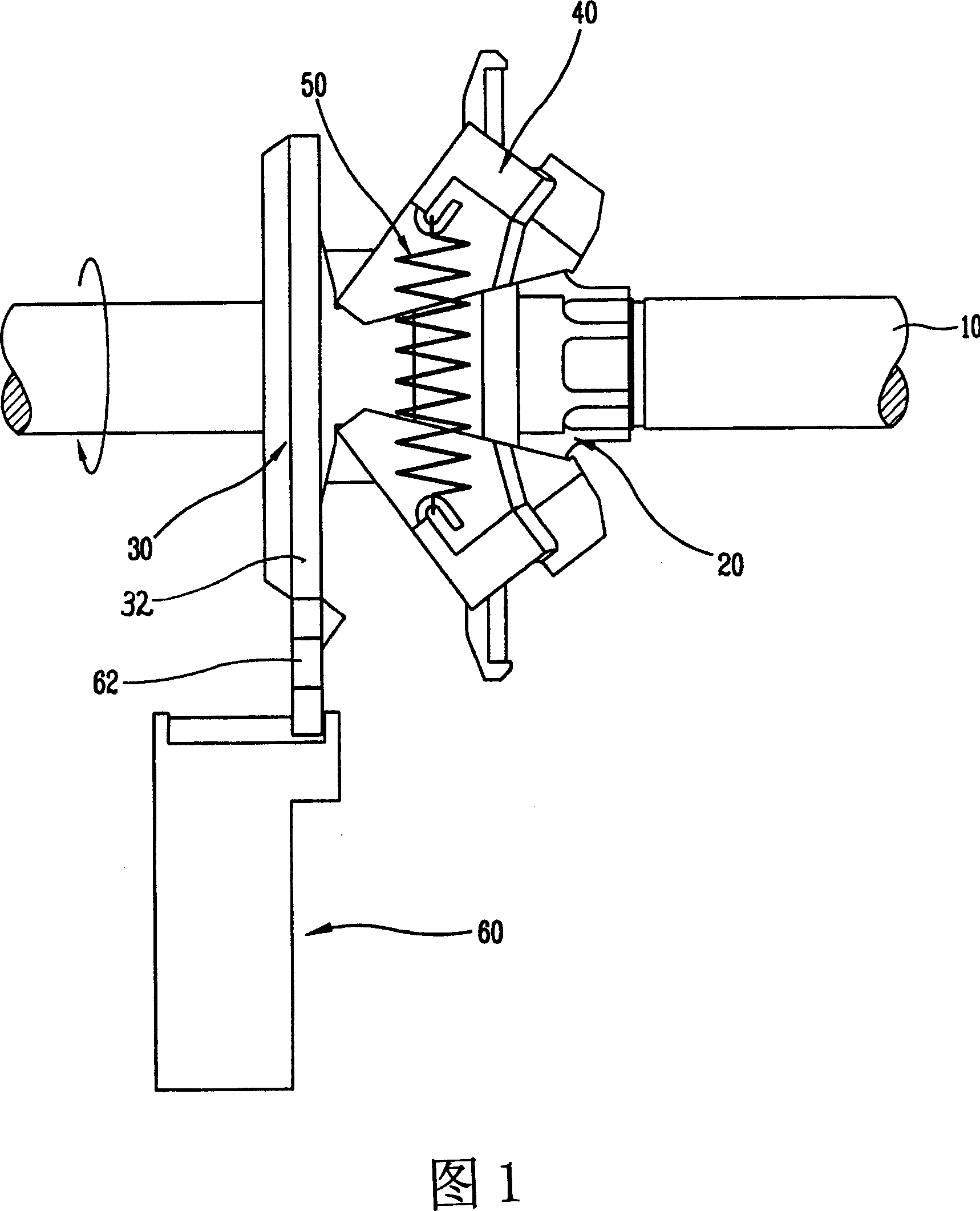

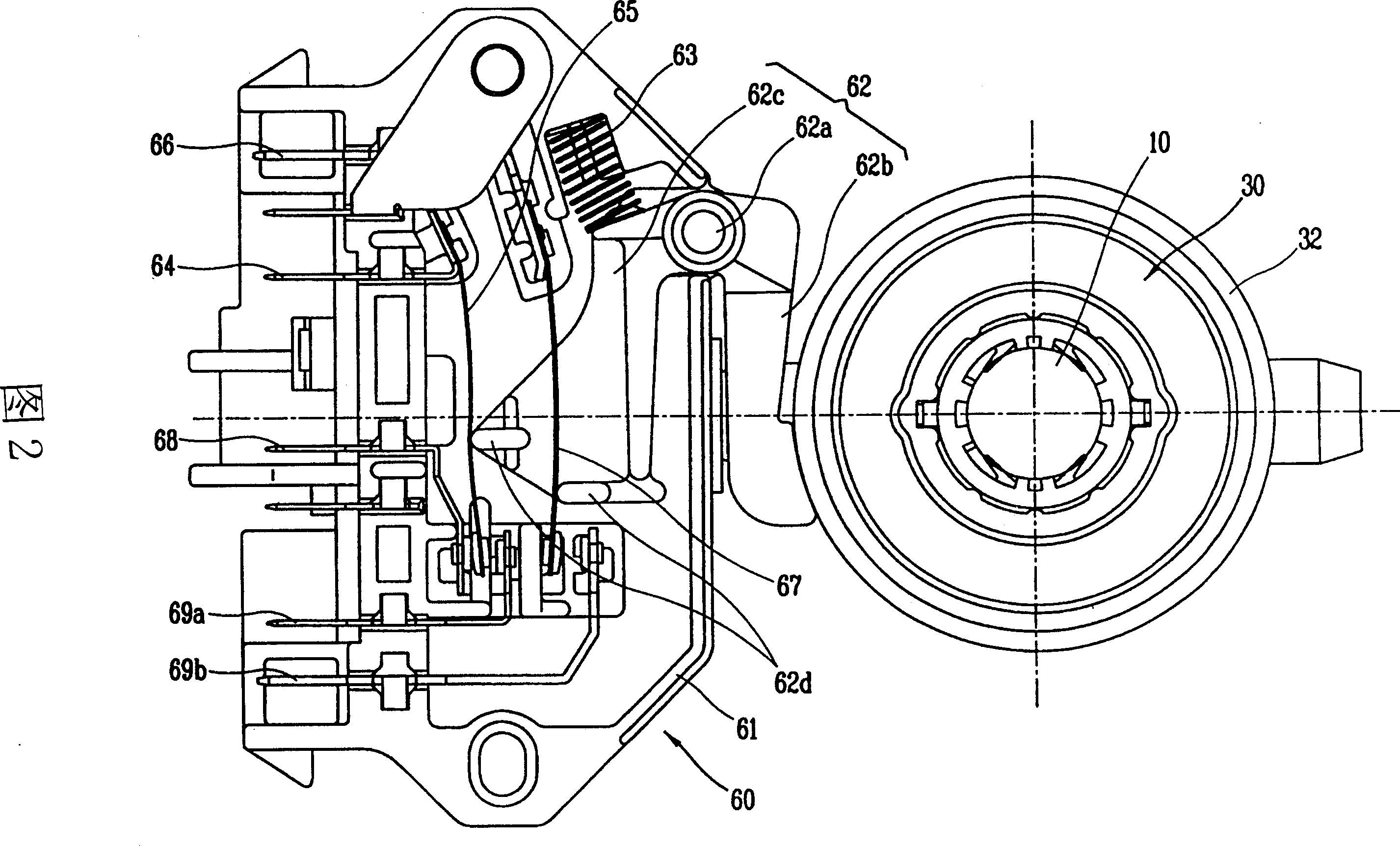

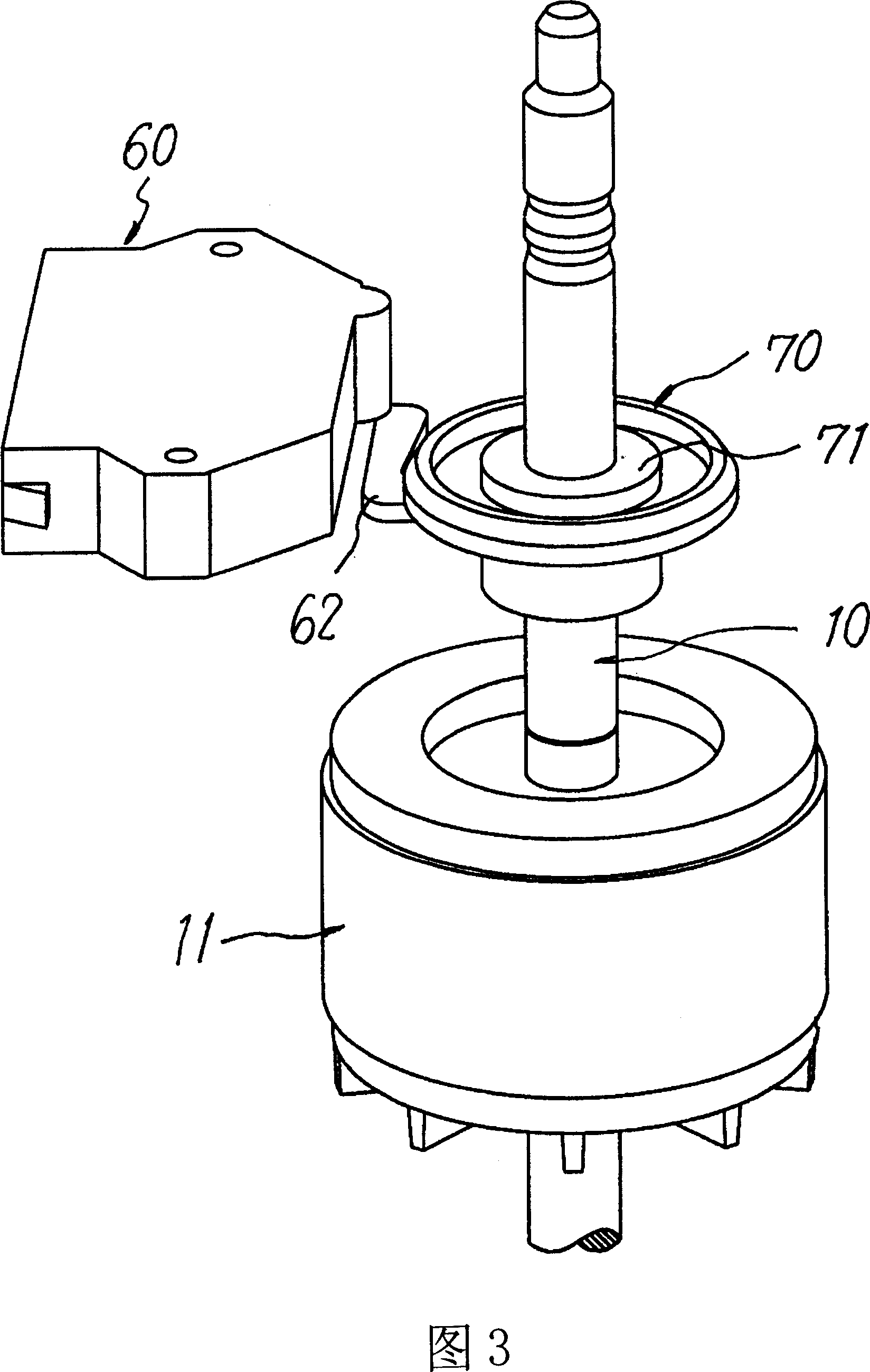

[0028] As shown in Figures 3 to 6, the present invention includes: a rotating shaft 10 combined with a rotor iron core 11 of a single-phase induction motor; a sliding wheel 70 that is rotatably lifted and combined with the above-mentioned rotating shaft 10 to drive a centrifugal switch 60; The sleeve 71 provided at the central portion of the above-mentioned sliding wheel 70 and the spiral groove 81 and the spiral convex groove 82 formed on the inner and outer diameter portions of the rotating shaft 10 constitute the above-mentioned sliding wheel 70 due to the rotation of the above-mentioned rotating shaft 10. The sliding pulley drive unit 80 that rotates up and down.

[0029] The spiral groove 81 of the spiral sliding wheel driving portion 80 is formed only up to the upper end of the spiral convex groove 82 shown in FIG. 4 , so the spiral convex groove 82 can only move to this part.

[0030] As mentioned above, in the single-phase induction motor centrifugal switch driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com