Single main beam member of hoisting equipment

A technology of lifting equipment and single main girder, which is applied in the direction of supporting structure, load hanging components, track system, etc., can solve the problems of hidden safety hazards, increased weight, and large manual labor, so as to achieve the convenience of outer seam welding and not easy Effect of fatigue deformation and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

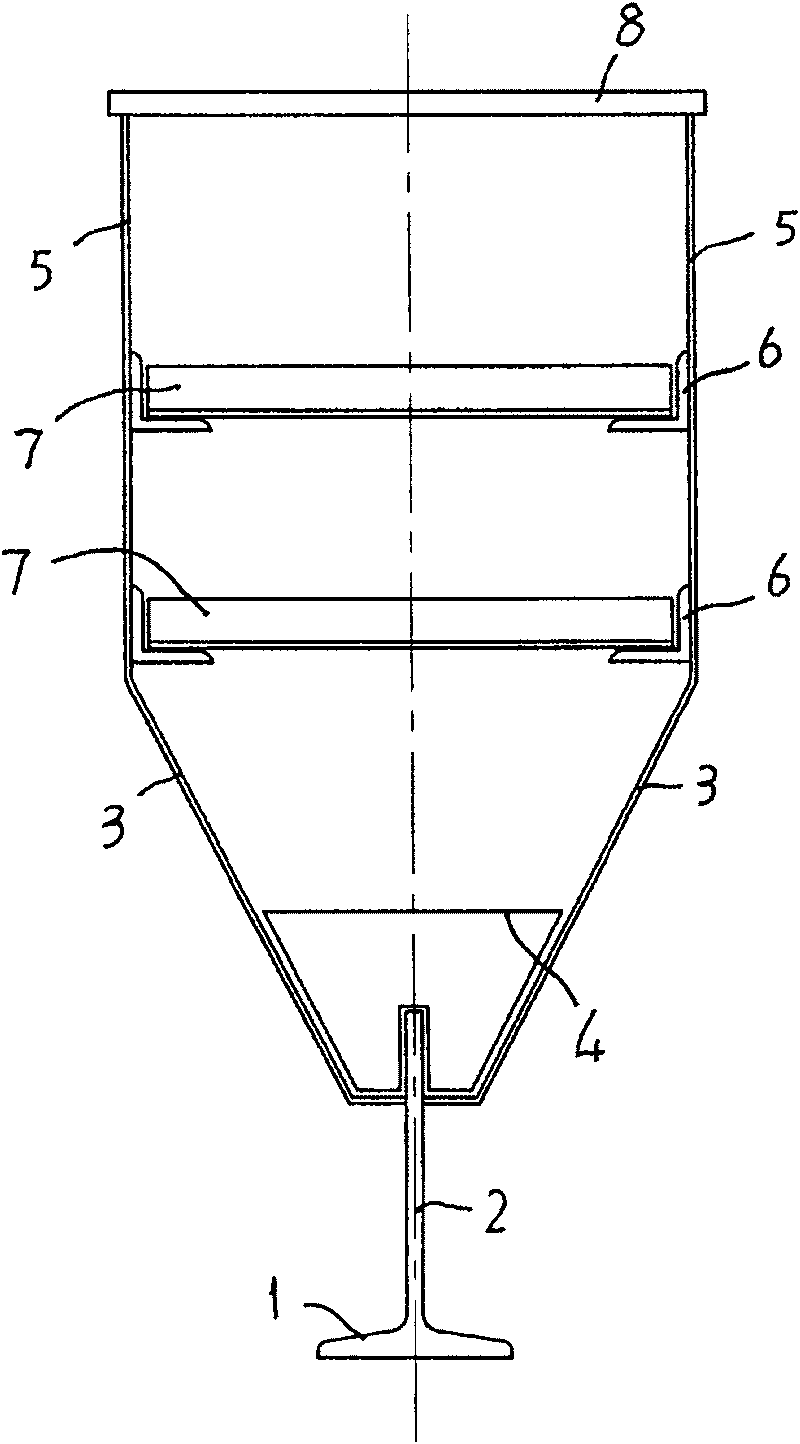

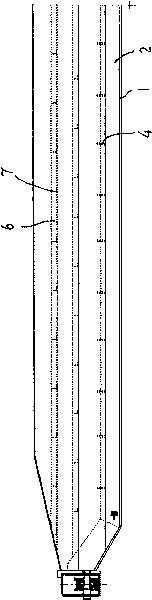

[0033] see figure 1 , figure 2 , The present embodiment is made of track and box body.

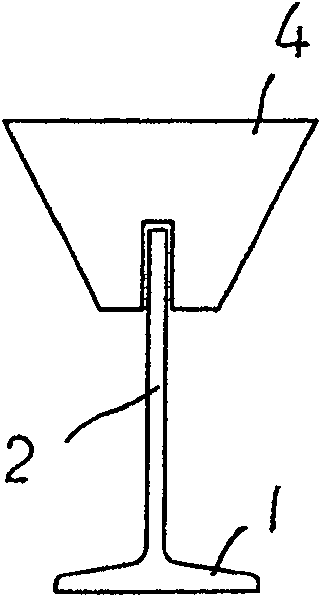

[0034] figure 1 As shown, the track adopts an inverted "T"-shaped cross-section structure, with its lower horizontal track tread 1 and its upright plate as the longitudinal main rib 2 of the track, and the top of the main rib 2 is connected to the two side plates arranged in a "V" shape 3, between the bottom of the "V" shaped side plate 3 and the main rib 2, a track positioning reinforced version 4 ( image 3 shown), and at the top of the "V" shaped side panel, the bending part is raised upwards to connect the upright wall panels 5 on both sides to form a box body.

[0035] figure 1 , figure 2 As shown, on the inner side walls of the wall panels 5 on both sides, a longitudinal process angle iron 6 is arranged along the track direction, and a horizontal horizontal support rib 7 is arranged between the longitudinal process angle irons 6 on both sides. Connect the widened and thickene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com