Air-lay web hydro-entangled composite entanglement product and preparing method and device

An air-laid and equipment technology, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of high production cost, poor strength, feel, and softness, and achieve easy-to-accept results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

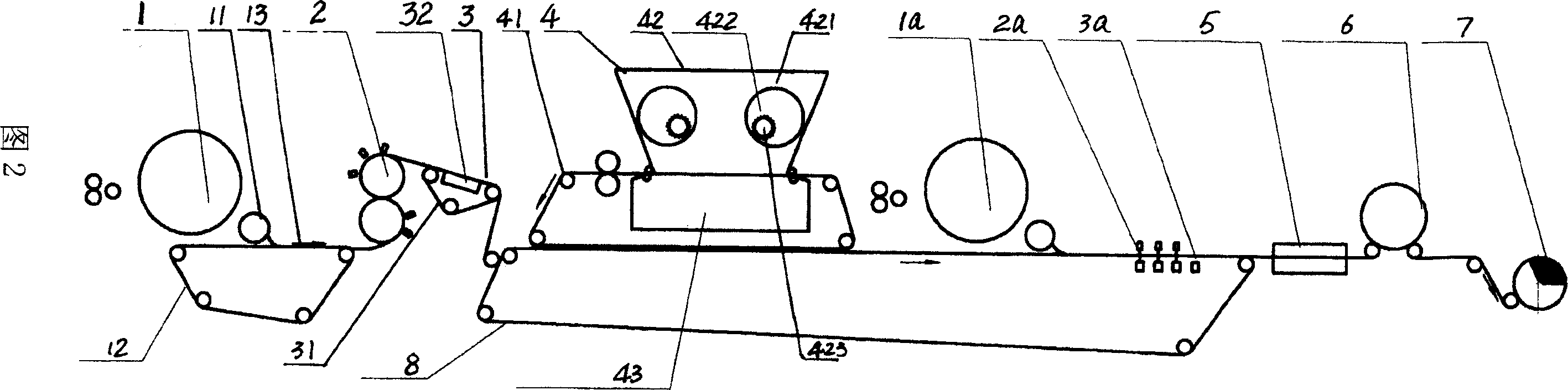

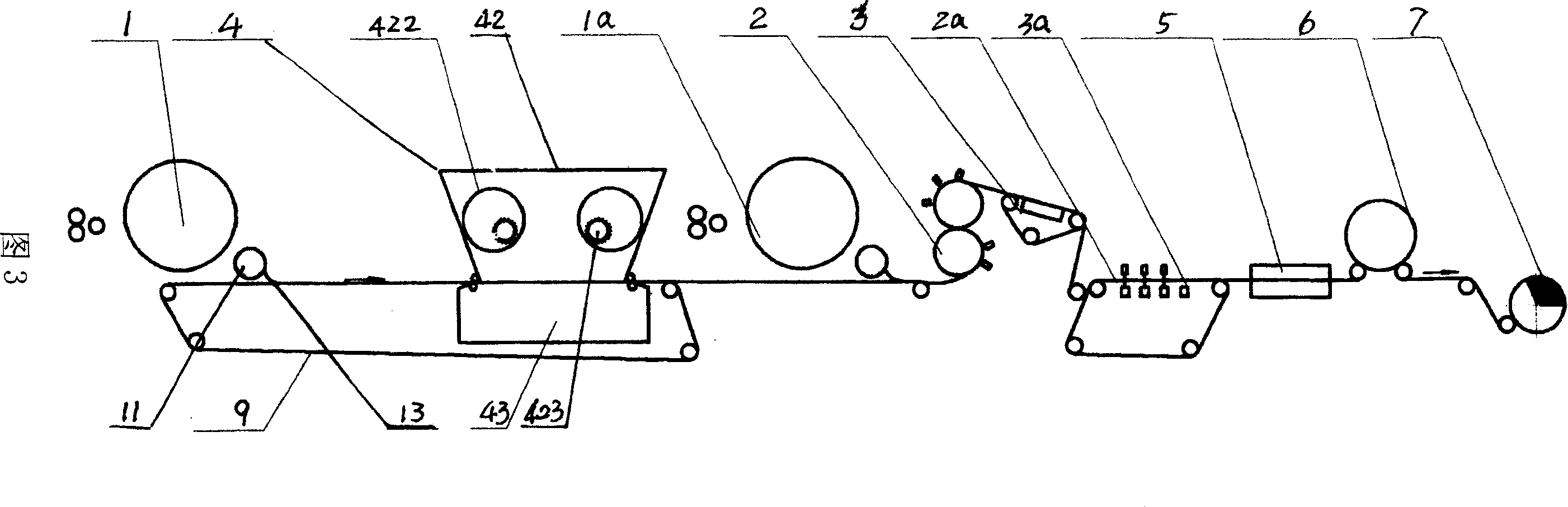

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0048]The air-laid hydroentangled composite entangled product has at least two-layer structure, at least one layer of which is a fluff pulp ultra-short fiber web after pulp debonding, at least one layer is a non-woven short fiber web, and the fluff pulp ultra-short fiber web The fibers of the nonwoven staple fiber web are intertwined and entwined. The weight of the spunlace composite entanglement product is 30-100g / m 2 . Wherein the content of the ultra-short fiber fluff pulp is 10-70%, the length of the ultra-short fiber is 1.0-2.5mm, and the content of the non-woven short fiber is 30-90%.

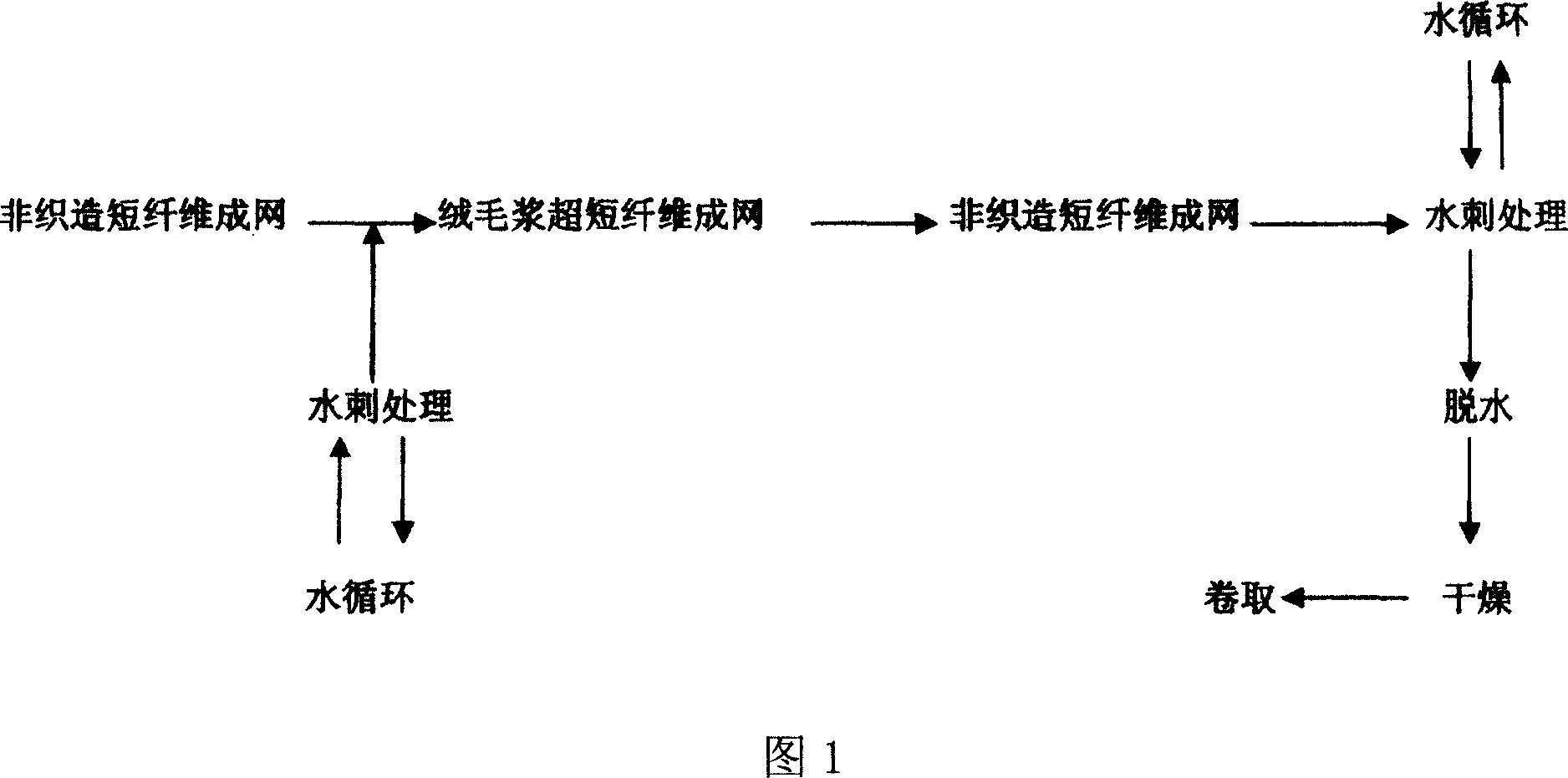

[0049] Referring to Fig. 1, a kind of method of manufacturing above-mentioned air-laid hydroentangled composite entanglement product comprises the steps:

[0050] 1. The fluff pulp ultra-short fiber web is formed by air-laid dry-laid paper forming equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com