Production method of low hexachlorobenzene content chlorothalonil

A production method, chlorothalonil technology, which is applied in chemical instruments and methods, botanical equipment and methods, biocides, etc., can solve problems such as difficulty in natural degradation, achieve low cost, increase pH value, and improve controllability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

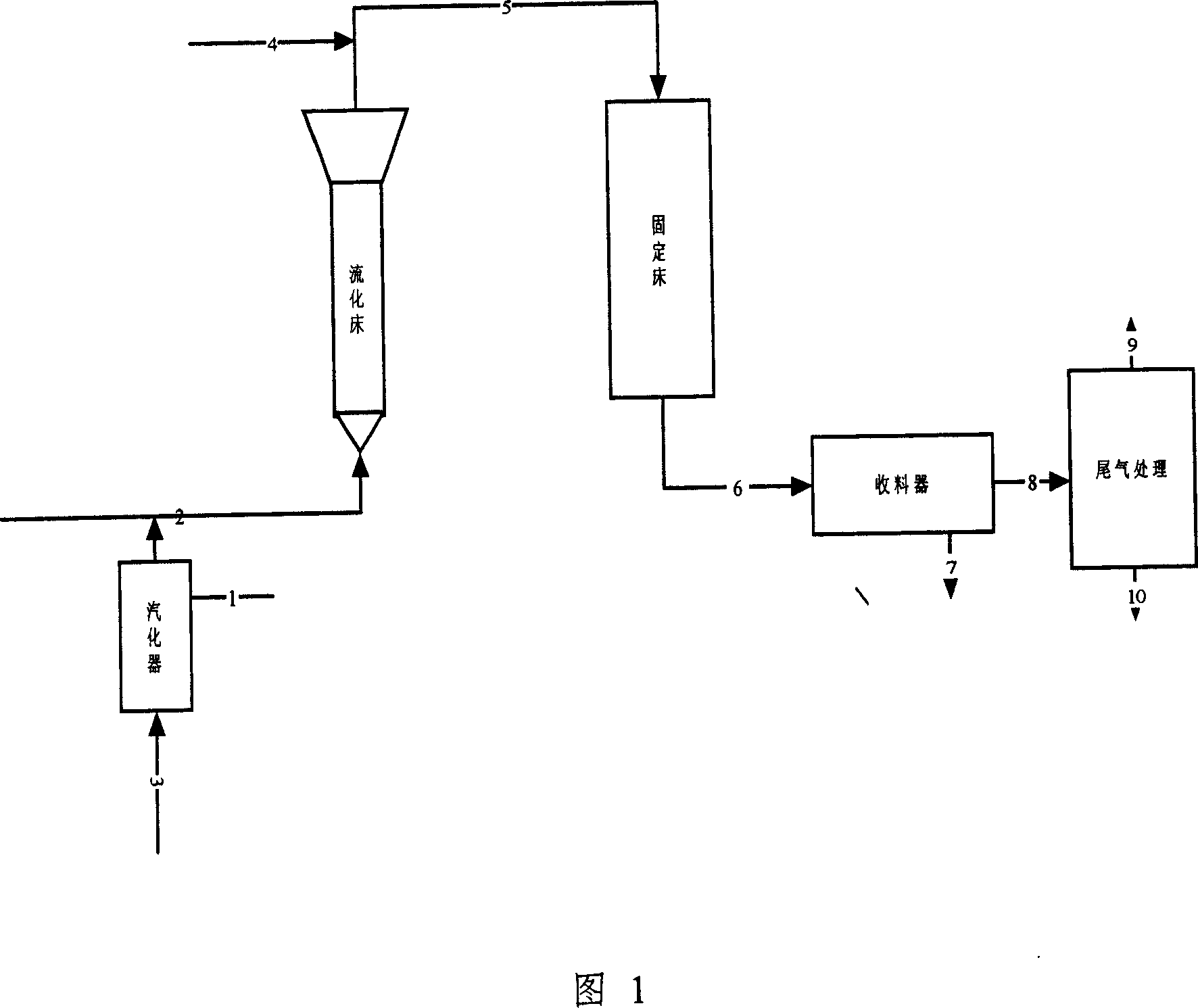

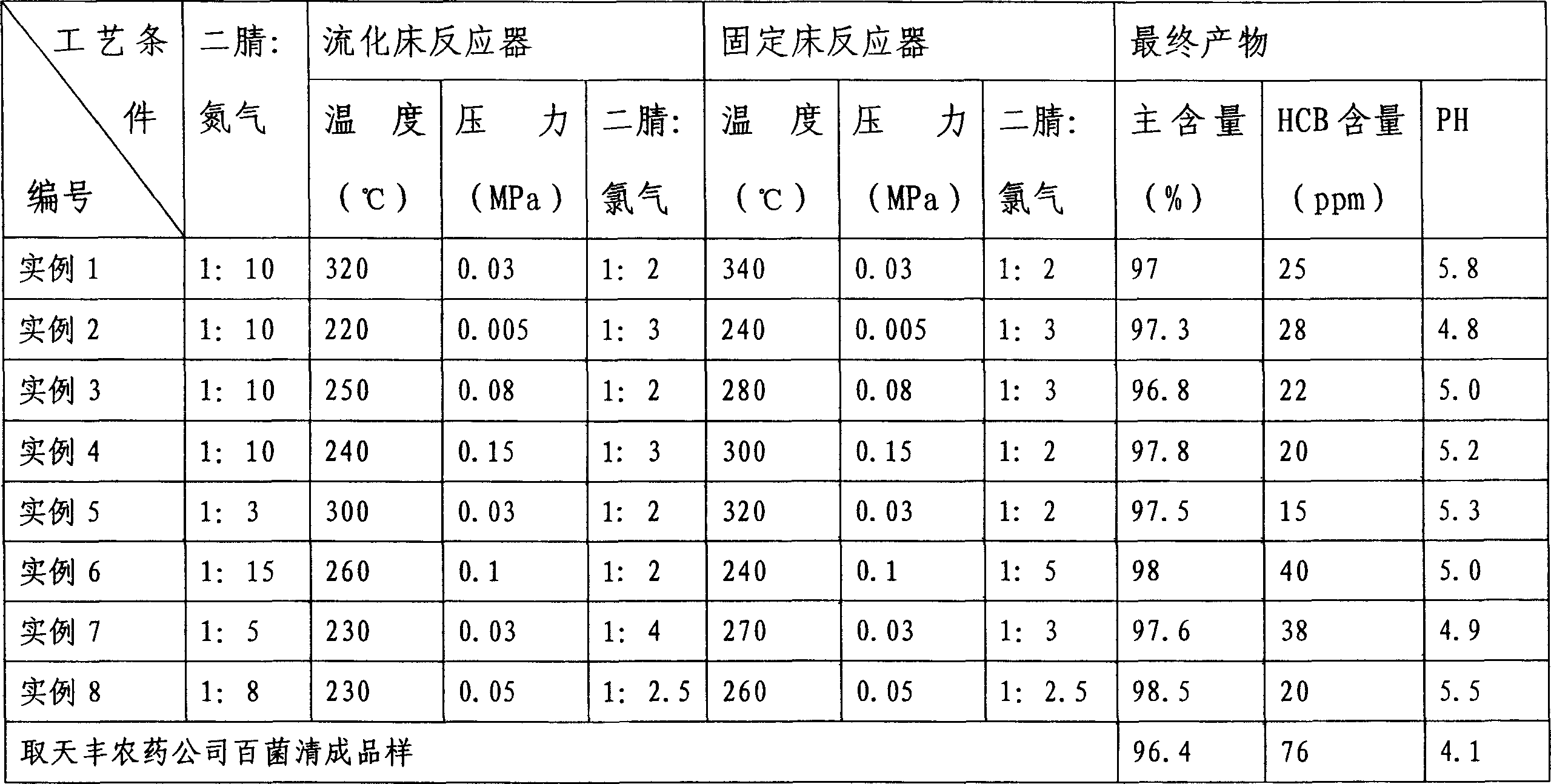

[0019] As shown in Figure 1, isophthalonitrile is fed into the vaporizer from line 1, and the feed amount is 1 mol / hr. After the isophthalonitrile is completely vaporized, the nitrogen gas input from the pipeline 3 is taken out of the vaporizer, and the flow rate of the nitrogen gas is 10 mol / hr. It is mixed with the chlorine gas in pipeline 2, and enters the fluidized bed from under the distribution plate of the fluidized bed, and the flow rate of the chlorine gas is 2mol / hr. The fluidized bed is equipped with a fluidized bed catalyst, the reaction temperature is set at 320°C, and the pressure is 0.03MPa, and the first step of reaction is carried out in the fluidized bed. The reaction product is mixed with the chlorine gas transported by the pipeline 4, and the flow rate of the chlorine gas is 2mol / hr, and enters the fixed bed for the final stage of chlorination. The fixed bed is equipped with a fixed bed catalyst, and the set reaction temperature is 340° C. and the pressure...

Embodiment 2

[0021] Repeat embodiment 1, following difference is arranged: the fluidized bed reaction temperature is 220 ℃, and the amount of chlorine entering the fluidized bed reactor is 3mol / hr, and the pressure in the fluidized bed reactor is stable at 0.005Mpa; The fixed bed reaction temperature is At 240°C, the amount of chlorine gas entering the fixed bed reactor is 3mol / hr, and the pressure in the fixed bed is stable to 0.005Mpa. Sampling analysis, test results are shown in Table 1.

Embodiment 3

[0023] Repeat Example 1, with the following differences: the amount of chlorine entering the fluidized bed reactor is 2mol / hr, the reaction temperature is 250°C, and the fluidized bed pressure is stable to 0.08Mpa. The feed rate of chlorine into the fixed bed reactor is 3mol / hr, the reaction temperature is 280°C, and the pressure is stable to 0.08Mpa. Sampling analysis, test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com