Movable pollution discharge cover for intensive shrimp pond

A mobile, shrimp pond technology, applied in water conservancy projects, open-air water surface cleaning, construction, etc., can solve the problems of cumbersome cleaning and screen changing operations, affecting shrimp harvesting operations, poor safety performance, etc. The effect is obvious and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples further illustrate the invention but are not to be considered as limiting.

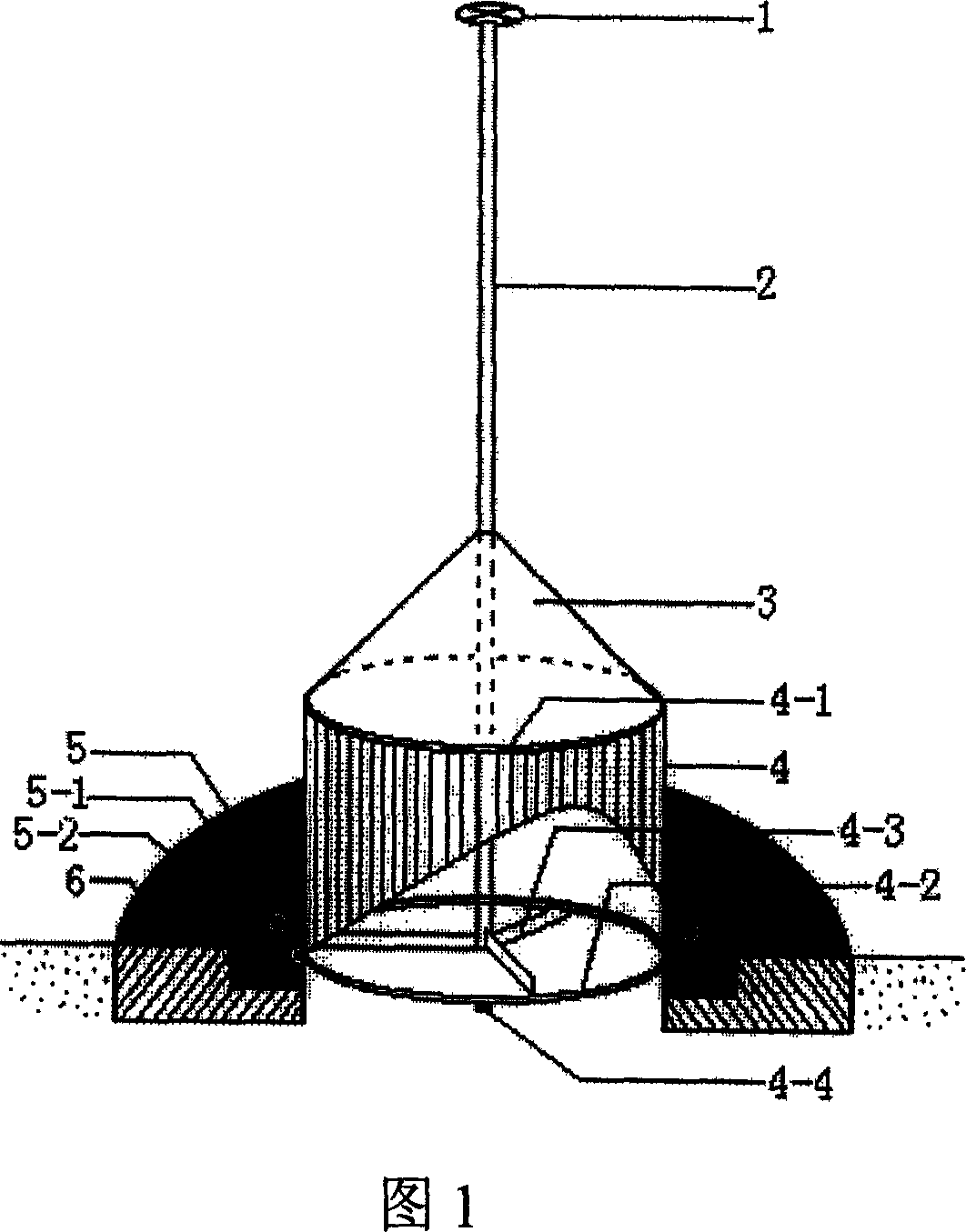

[0017] As shown in Figure 1, a mobile sewage cover for intensive shrimp ponds is composed of an operating panel 1, an operating rod 2, a conical pressure-resistant cover 3, a fence 4 and a base 5;

[0018] The top of the operating rod 2 is connected to the cross bar of the operating panel 1; the middle part is welded to the top of the pressure-resistant cover 3;

[0019] The fence 4 has upper and lower two annular fixed rings 4-1, 4-2, and the fence vertical bars are welded on the fixed rings 4-1, 4-2; the lower fixed ring 4-2 is welded with three-way stringers 4- 3. The center of the stringer is welded to the bottom of the operating rod 2; the steel plate thickness of the compression cover 3 is 2.5 mm, the lower part is welded on the top of the fence 4, and four ring-shaped fixing cards 4-4 are welded around the lower fixing ring 4-2; the base 5Reserved screw holes 5-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com