Suspension bed hydrocracking method using disperse type catalyzer

A dispersed catalyst and hydrocracking technology, applied in hydrocarbon oil cracking, petroleum industry and other directions, can solve the problems of high equipment investment and complex process, save equipment investment, promote hydrogenation reaction, and ensure stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

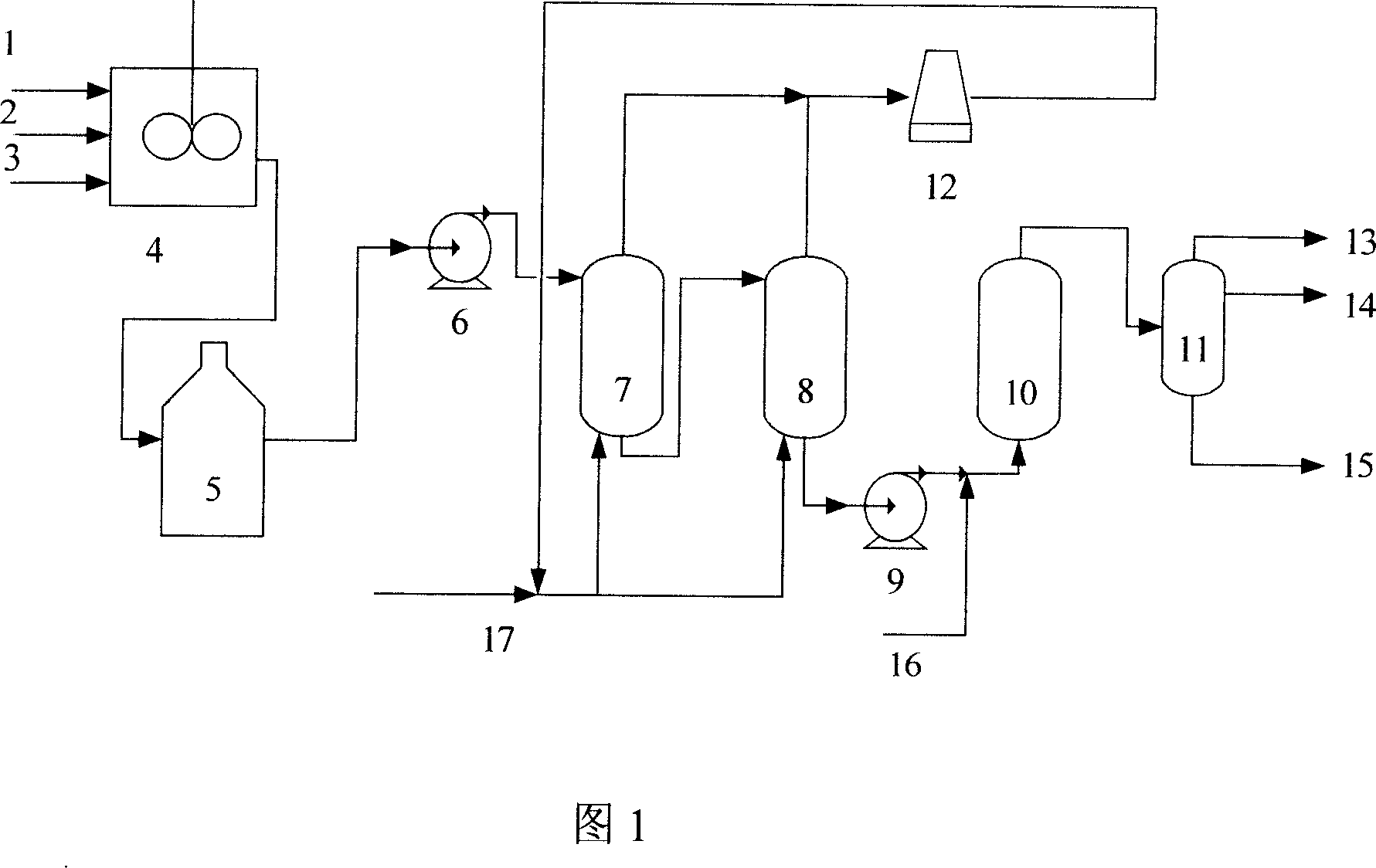

[0023] As shown in Figure 1, the process flow for hydrogenation of residual oil using a dispersed catalyst suspension bed is as follows: feed raw material 1, catalyst 2 and vulcanizing agent 3 into mixer 4 according to the required ratio, wherein the mixer can be a multi-stage shear Cutting pump, magnetic stirrer, emulsifier, etc., the uniformly mixed raw materials enter the raw material tank 5, and are sent to the low-pressure low-temperature vulcanizer 7 and the low-pressure high-temperature vulcanizer 8 successively through the low-pressure pump 6, and are fully vulcanized by countercurrent contact with the low-pressure hydrogen gas 17. The gas extracts water vapor. Then the gas is recycled through the cooler 12 to remove water vapor, and the stream from the low-pressure high-temperature sulfurizer is mixed with the high-pressure hydrogen 16 through the high-pressure pump 9 and then enters the reactor 10 for hydrocracking reaction. After the reaction, the product stream pas...

Embodiment 1~3

[0030] This example is a suspension bed hydrocracking test using a dispersed catalyst. The specific operation process is shown in Figure 1. Raw material 1, catalyst 2 and vulcanizing agent 3 are uniformly mixed by the shear pump and then enter the raw material tank 5, and then sent to the low-pressure low-temperature vulcanization reactor 7 and the low-pressure high-temperature vulcanization reactor 8 successively through the low-pressure pump 6, and contact with the low-pressure hydrogen 17 countercurrently. Fully vulcanize and gas out water vapor, then the gas passes through the cooler 12 to remove the water vapor for recycling, and the stream from the low-pressure high-temperature vulcanizer passes through the high-pressure pump 9 and mixes with the high-pressure hydrogen 16, and then enters the reactor 10 for hydrocracking reaction. The hydrocracking reaction is carried out under certain reaction conditions. After the reaction, the product stream passes through a fraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com