Photoelectric sensor, optical module and method of producing same

A photoelectric sensor, optical module technology, applied in semiconductor/solid-state device manufacturing, optics, optical components, etc., can solve problems such as reduced yield, large changes in light behavior, and damage to lenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described below through an example, wherein the present invention is applied to a light projector and a light receiver of a photoelectric sensor as an optical module. In the examples described, the same components are denoted by the same reference numerals, and their descriptions will not be repeated.

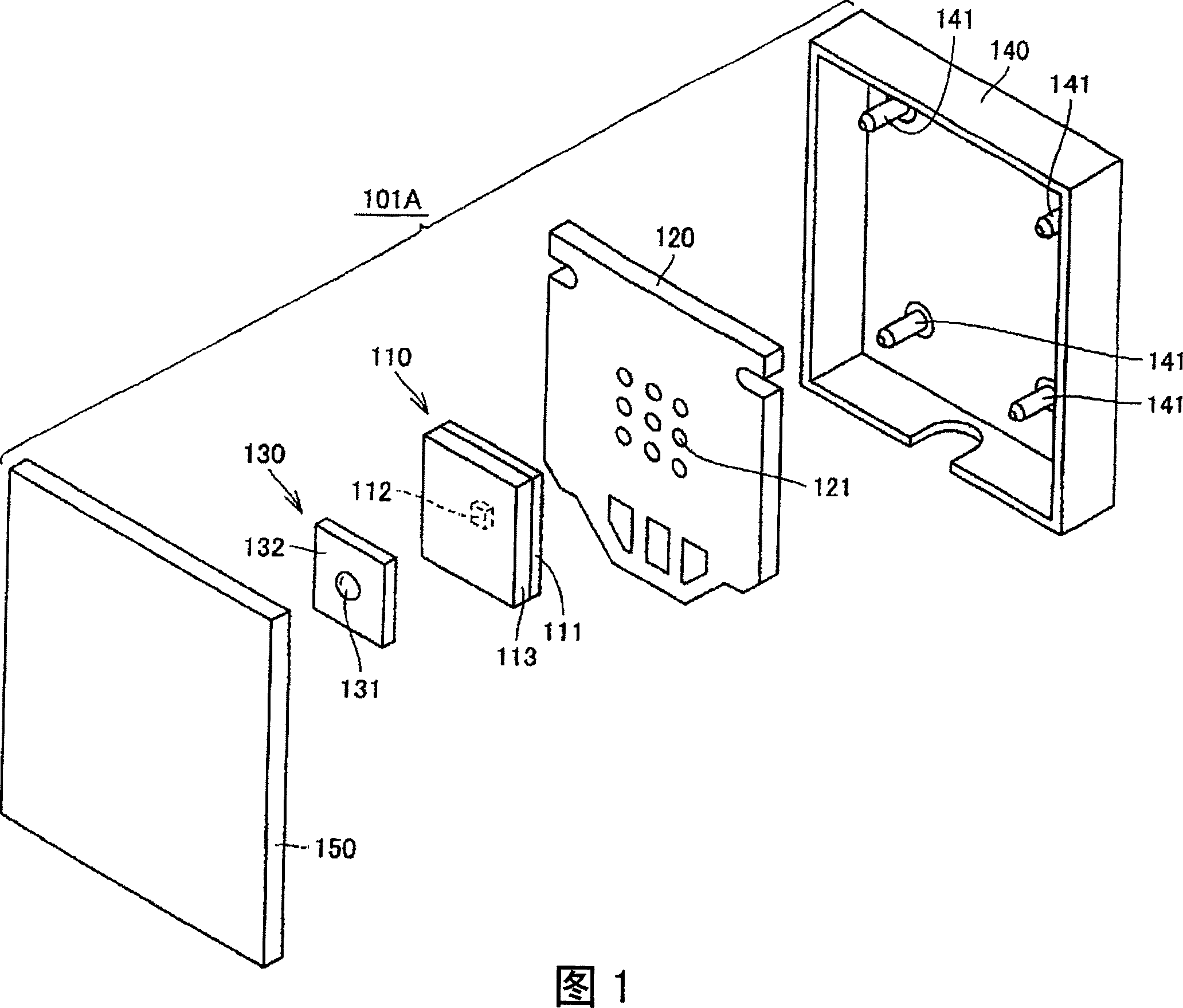

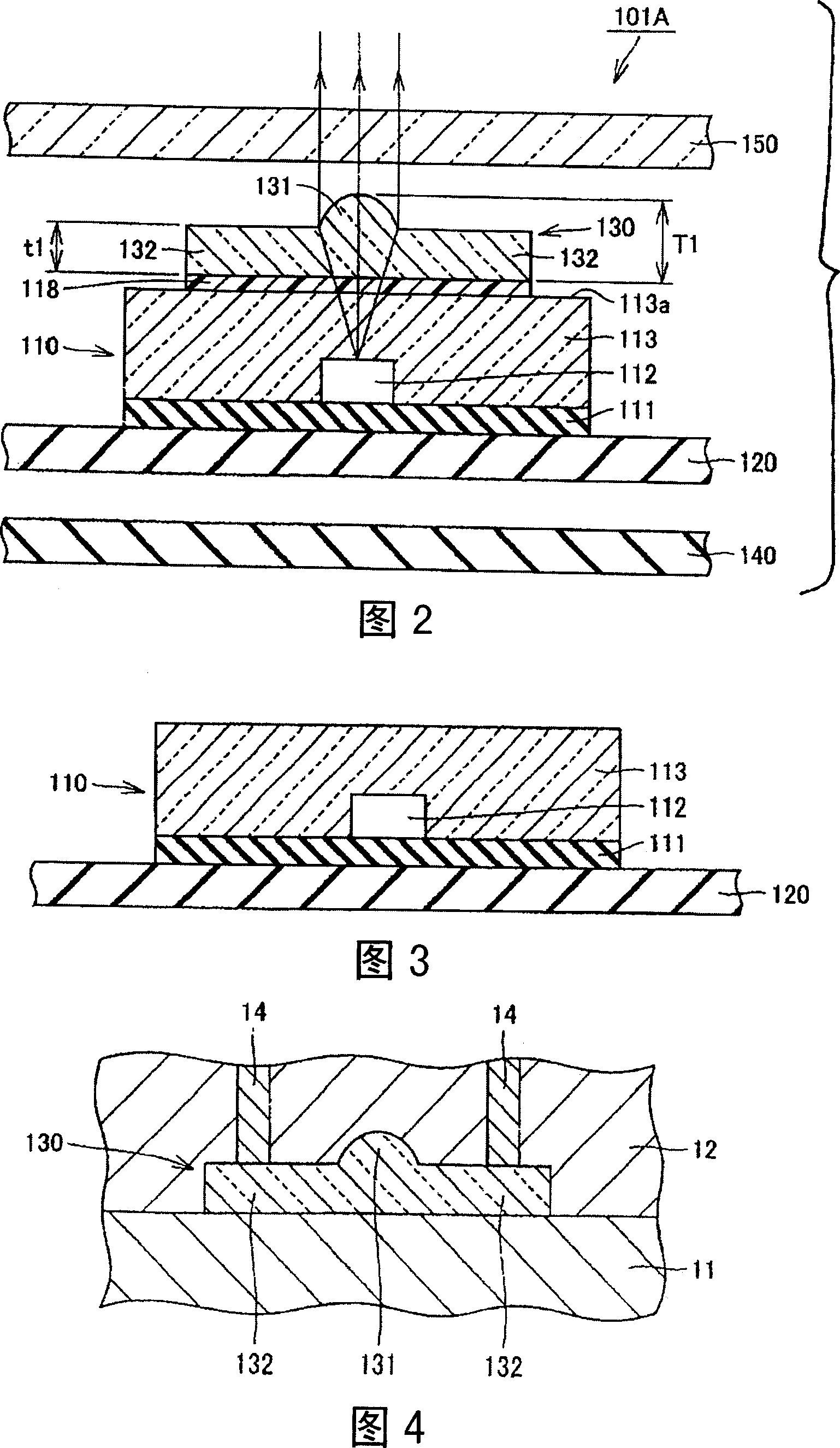

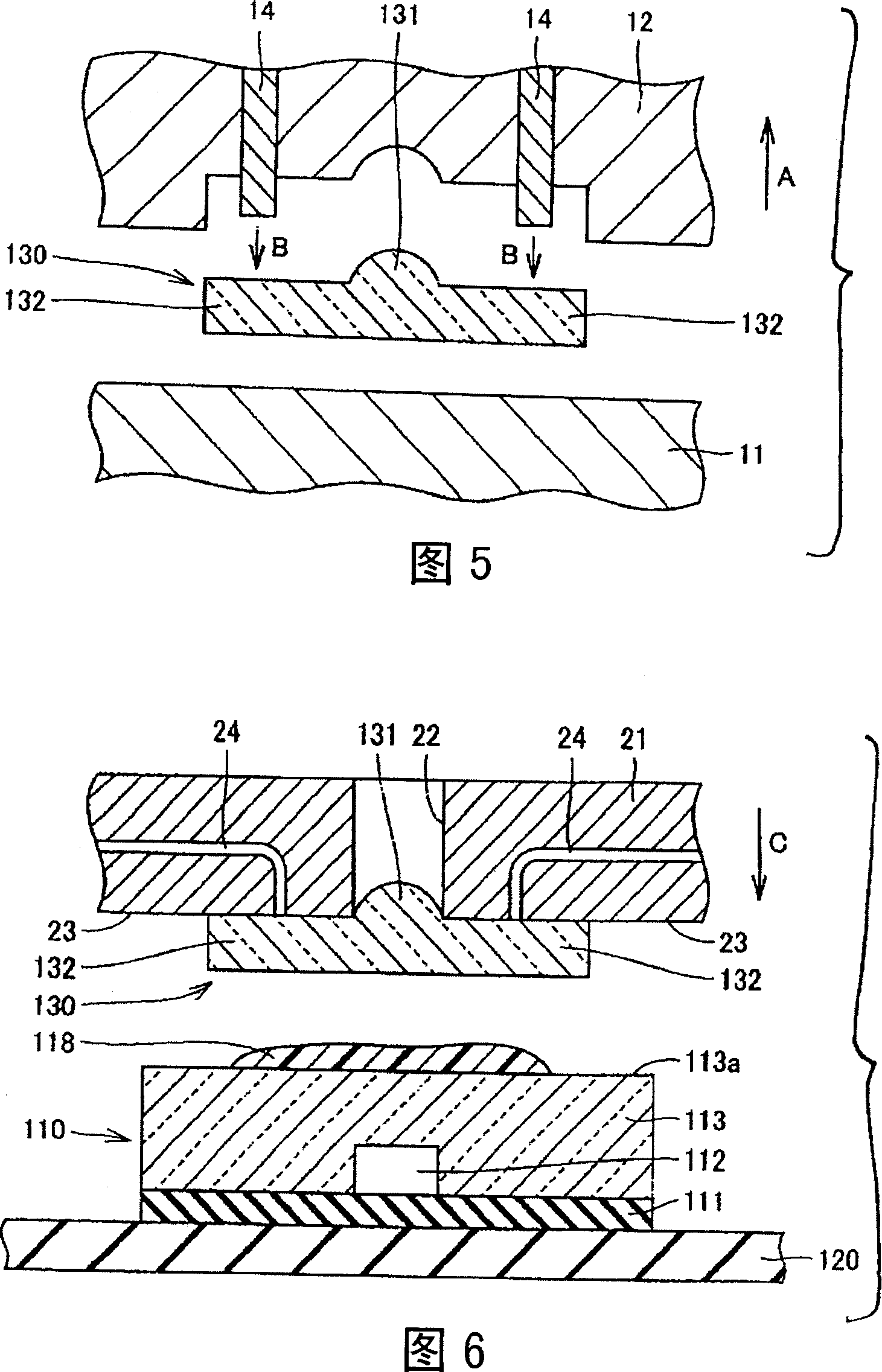

[0048] FIG. 1 is an exploded perspective view of a light projector 101A according to a first embodiment of the present invention, and FIG. 2 is a partial cross-sectional view of the assembled light projector 101A. The structure of the light projector 101A will be described below with reference to FIGS. 1 and 2 .

[0049] As shown in FIGS. 1 and 2 , the light projector 101A according to the first embodiment of the present invention includes an IC package 110 in the form of a CSP, a mounting substrate 120 , a lens unit 130 , a housing 140 and a cover 150 . A CSP-type IC package 110 includes an intermediate substrate 111 , an LED 112 as a semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com