Method and device for mould pressing preparing artistic handicraft using plant waste material

A plant waste material and handicraft technology, which is applied to the device for preparing art handicrafts by molding plant waste materials, and in the field of art handicrafts prepared by plant waste molding, can solve the problems that the utilization rate of wood is only 50%, it is not suitable for large-scale production, and it is unfavorable for environmental protection. Not easy to deform and crack due to compression, low cost and short production cycle

Inactive Publication Date: 2007-05-02

SOUTH CHINA UNIV OF TECH +1

View PDF0 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] (1) Manual production is required, the production cost is high, the cycle is long, and the efficiency is low, it is difficult to meet the large demand of the market, and it is not suitable for large-scale production;

[0005] (2) Wood waste is serious in the production process, and the utilization rate of wood is only about 50%;

[0006] (3) Not conducive to environmental protection

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0040]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

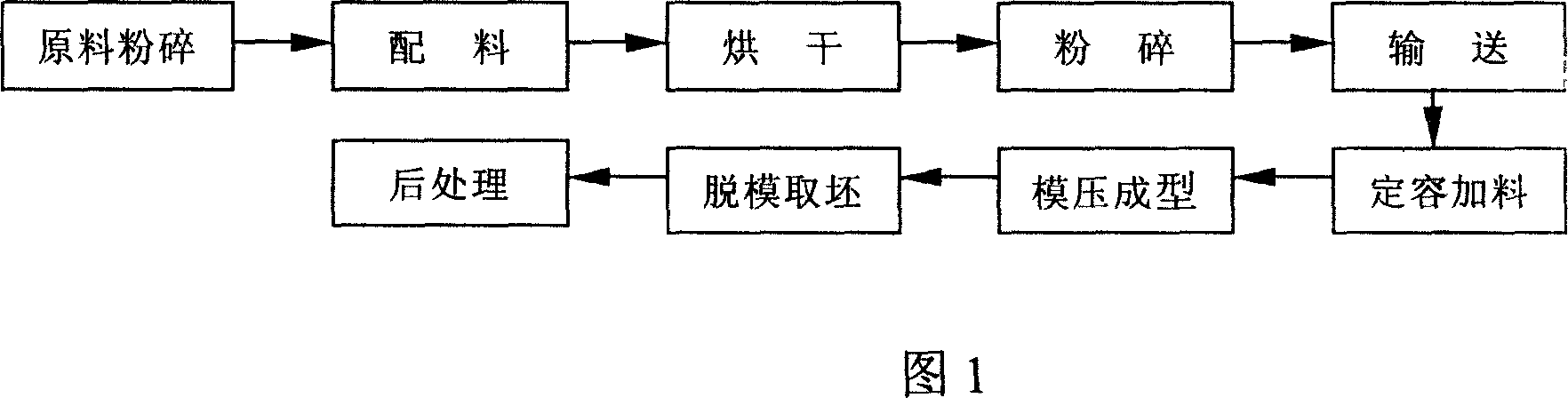

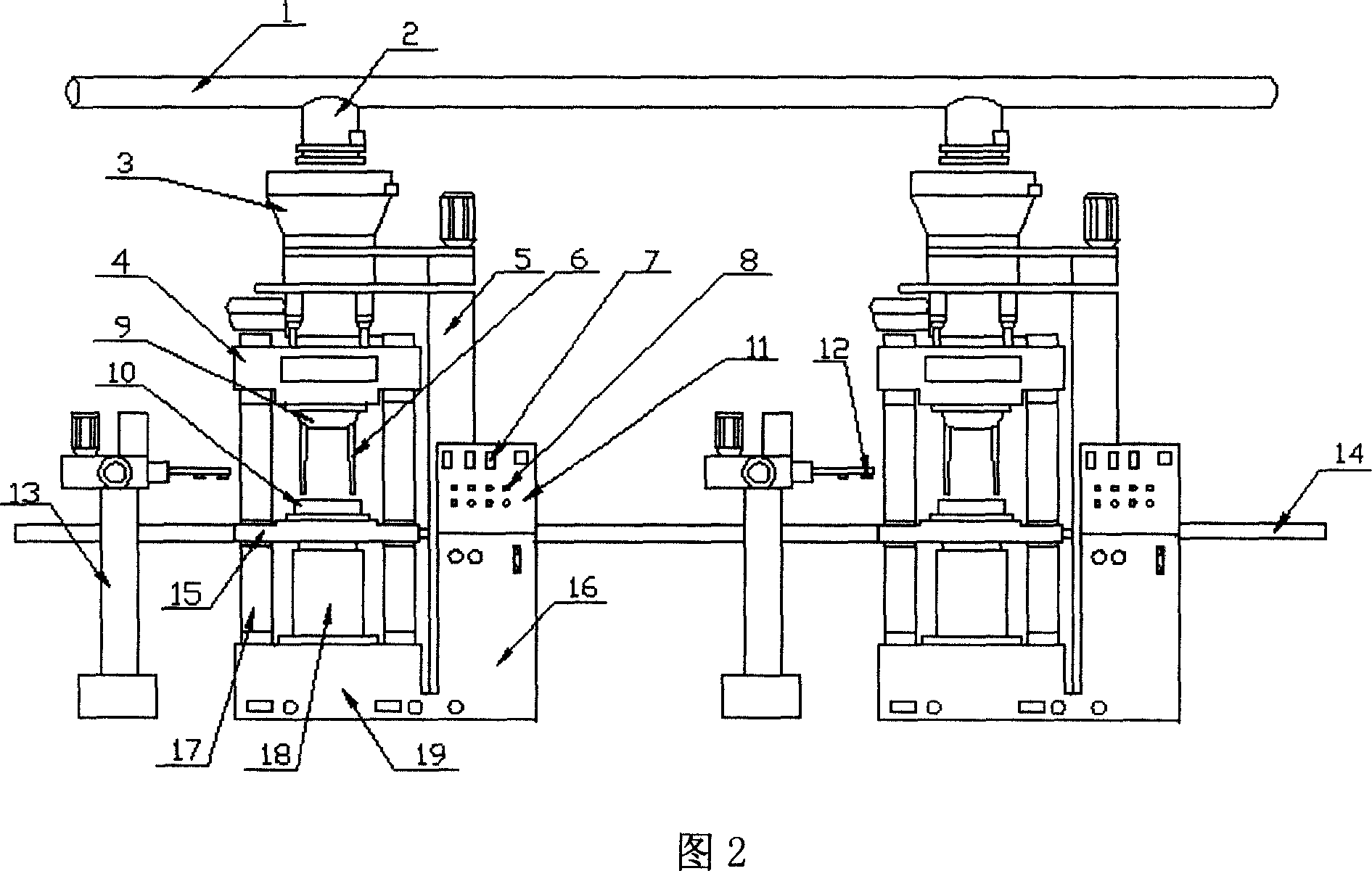

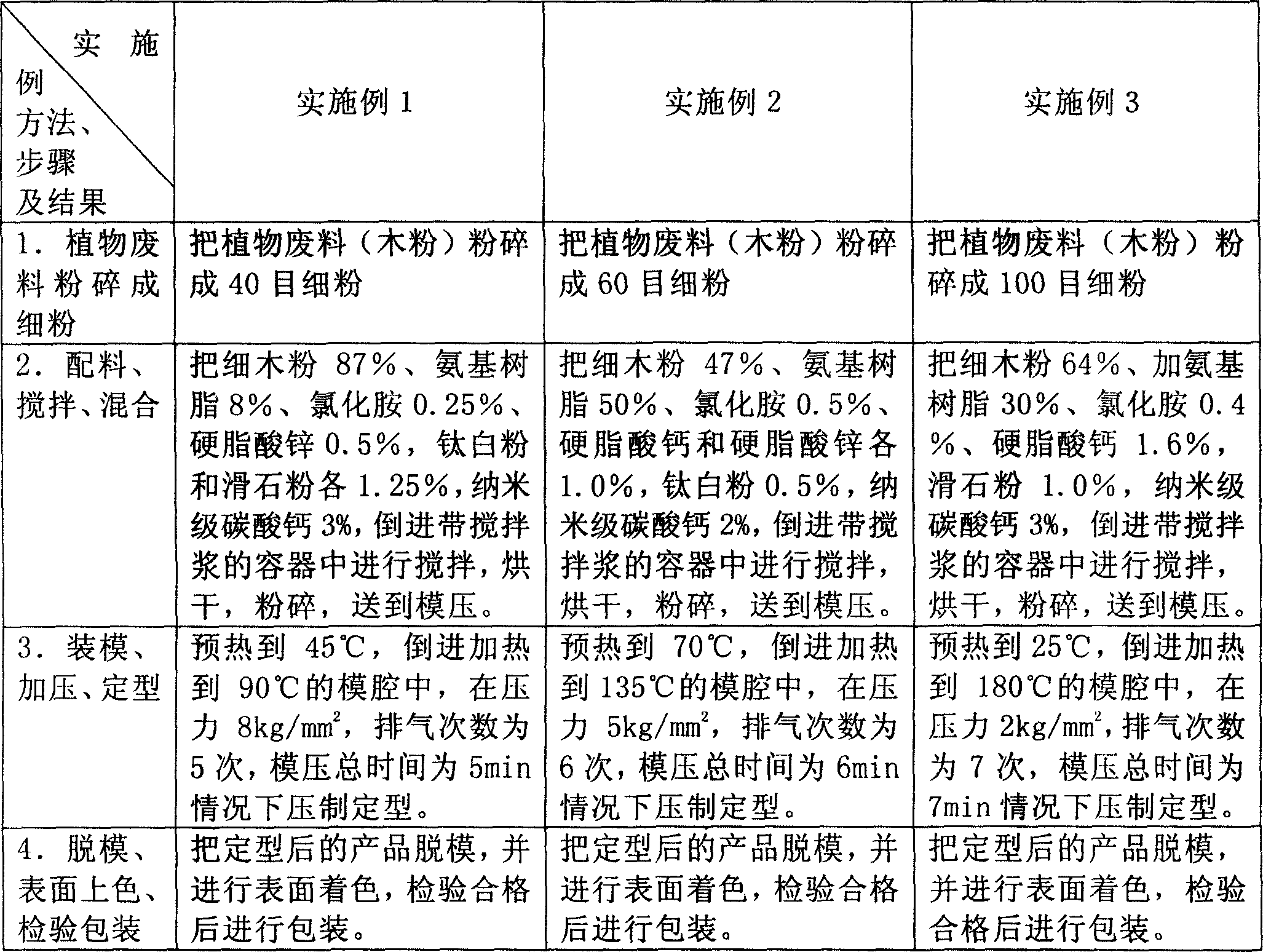

A die pressing method for preparing artworks from the vegetative waste includes such steps as breaking raw vegetative waste, mixing with amino resin, calcium stearate, zinc stearate, coloring agent, and calcium carbonate nanoparticles, baking, pulverizing, die pressing, and post treating. Its apparatus is composed of powder delivering pipe, induction valve, quantitative induction hopper, upper and lower dies and their holding plates, feeding controller, discharging suction cup and manipulator, control box with meters and push buttons, conveying belt, movable bench, vertical columns, and cylinder.

Description

technical field [0001] The invention relates to a compression molding method, in particular to a method for preparing arts and crafts by molding plant waste. [0002] The invention also relates to a device for preparing arts and crafts by molding plant waste materials. Background technique [0003] At present, wood, resin and PU (polyurethane) materials are mainly used in the production of picture frames, photo frames, mirror frames and carved handicrafts. Picture frames, photo frames, mirror frames and carved handicrafts made of resin and PU materials are suspected of fakes in texture and expensive. Picture frames, photo frames, mirror frames and carved handicrafts made of wood have the following deficiencies: [0004] (1) Manual production is required, the production cost is high, the cycle is long, and the efficiency is low, it is difficult to meet the large demand of the market, and it is not suitable for large-scale production; [0005] (2) Wood waste is serious in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B27N5/00B27L11/00B27N1/02B27N3/08B27N7/00

Inventor 胡青春张丽燕骆家宗林正禄

Owner SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com