Method for plating printed circuit board and printed circuit board manufactured therefrom

A technology of printed circuit boards and printed circuits, which is applied in the direction of printed circuit manufacturing, printed circuits, printed circuit components, etc., and can solve problems such as applications that are not suitable for low current and high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

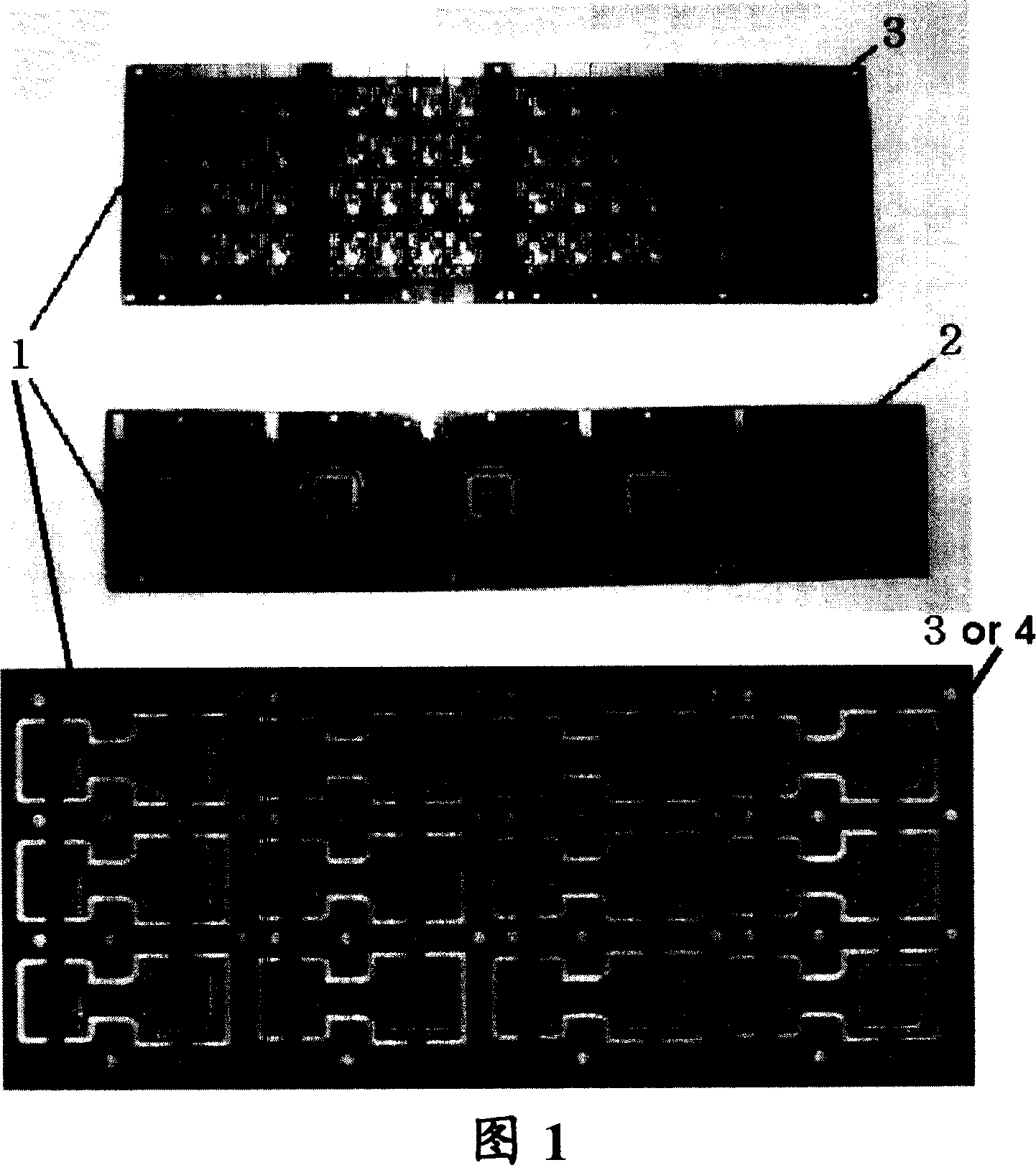

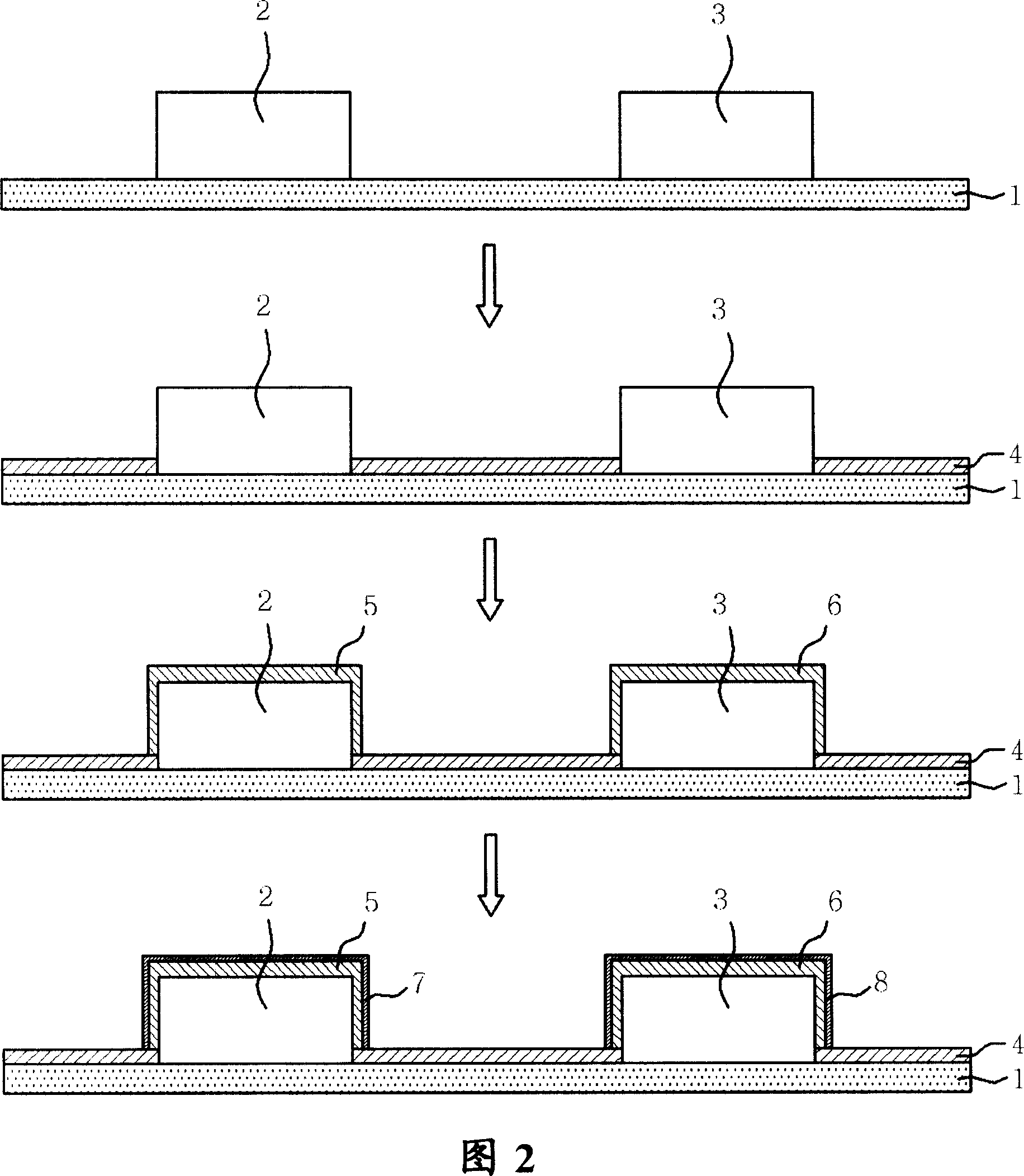

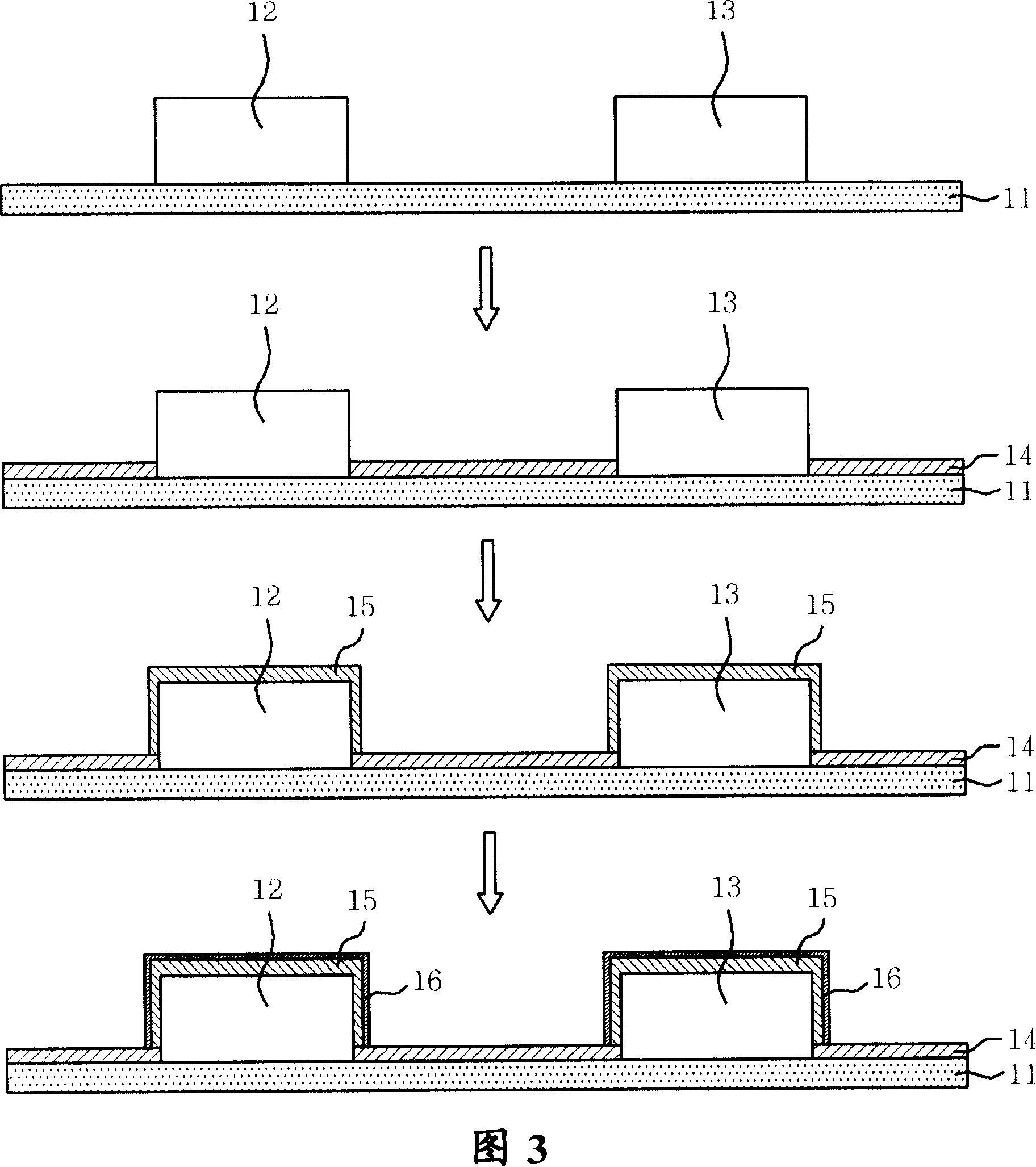

Image

Examples

Embodiment 1

[0087] On the copper layer of the printed circuit board of pretreatment, by palladium: the ratio of phosphorus is 96.7: 3.3 (wt%) the palladium-phosphorus alloy plating that constitutes to thickness is 0.2 μ m, then forms thickness on the palladium phosphorus alloy plating layer 0.05μm gold plating.

Embodiment 2

[0089] The same procedure as in Example 1 was repeated except that a palladium-boron alloy composed of a palladium:boron ratio of 99.3:0.7 (wt%) was used instead of palladium-phosphorus.

Embodiment 3

[0091] The same procedure as in Example 1 was repeated except that pure palladium was used instead of the palladium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com