United system of pulsion, power supply, steam supply of fuel gas-steam power of giant shipping

A technology of steam power and combined system, which is applied in the field of ship power, can solve the problems of inability to improve thermal efficiency, large fuel consumption, and large volume, and achieve significant energy-saving benefits and overall efficiency improvements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

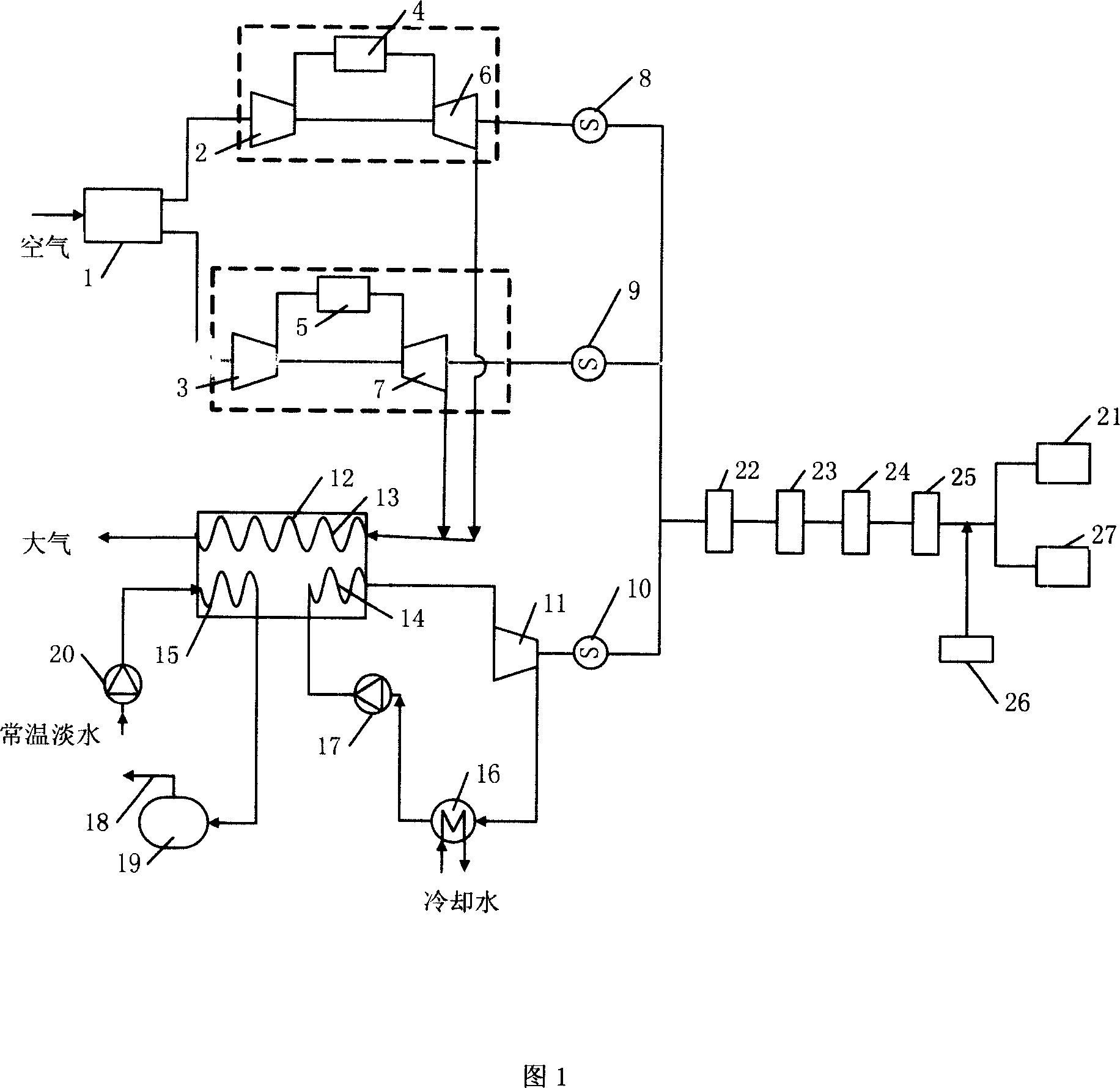

[0012] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0013] As shown in Figure 1, the present invention includes: air cleaner 1, A compressor 2, B compressor 3, A combustion chamber 4, B combustion chamber 5, A gas turbine 6, B gas turbine 7, A alternator 8 , B alternator 9, C alternator 10, steam turbine 11, flue gas boiler 12, flue 13, second vaporization pipe 14, first vaporization pipe 15, condenser 16, circulating water pump 17, steam supply pipe 18, steam drum 19, water pump 20, auxiliary power network 21, switchboard 22, transformer 23, harmonic filter 24, frequency converter 25, monitoring controller 26, pod type electric thruster 27.

[0014] Among them, A compressor 2, A combustion chamber 4 and A gas turbine 6 form a gas turbine unit, B compressor 3, B combustion chamber 5 and B gas turbine 7 form another gas turbine unit, and the two gas turbine units are connected in parallel; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com