Round alumina of containing silicon, and preparation method

A silica-alumina, spherical technology, which is applied in the field of spherical silica-containing alumina and its preparation, can solve problems affecting the performance of catalysts or catalyst carriers, failure to reach molecular state, dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A. Dissolve 30g of aluminum powder with an average particle size of 50 μm in 250g of 10% hydrochloric acid to prepare aluminum sol.

[0030] B. Add 8.3g NaSiO 3 9H 2 O was dissolved in 55g of deionized water, ion-exchanged through a 001×7 (732) strongly acidic styrene-based cation exchange resin column to obtain an acidic silica sol, and then 35g of hexamethylenetetramine was added to the acidic silica sol to fully dissolve.

[0031] C. Mix the above two solutions thoroughly, and drop them into the vacuum pump oil at 70°C with a droplet-type dispersing dripper to form. The formed pellets were separated from the oil and aged at 130°C for 5 hours.

[0032] D. Wash the obtained product, dry at 140°C for 10 hours, and bake at 550°C for 6 hours to obtain SiO 2 γ-shaped spherical alumina carrier with a content of 3%.

[0033] It has been determined that the specific surface area of the spherical alumina carrier is 223m 2 / g, the pore volume is 0.82ml / g, and the bulk de...

Embodiment 2

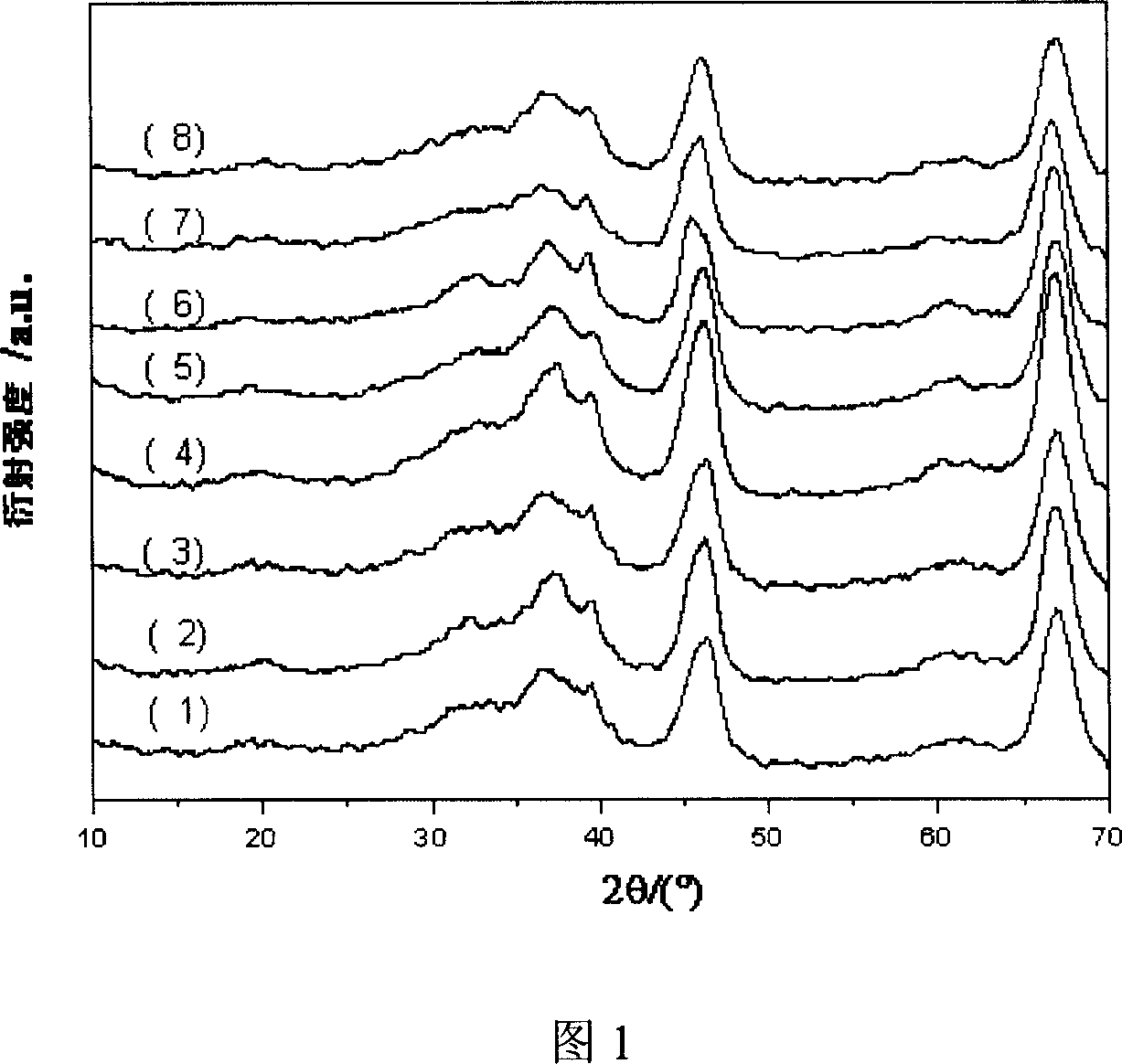

[0035] Keep other preparation conditions constant in embodiment 1, in step B with 14.1g NaSiO 3 9H 2 O was dissolved in 70 g of deionized water, and the resulting SiO 2 5% gamma spherical alumina. Its specific surface area is 266m 2 / g, the pore volume is 0.94ml / g, and the bulk density is 0.46g / cm 3 , the average particle size is 2.3mm, and the Na content is 21ppm. The XRD spectrum is shown in curve 2 in Fig. 1 .

Embodiment 3

[0037] Keep other preparation conditions constant in embodiment 1, in step B with 23.3g NaSiO 3 9H 2 O was dissolved in 90 g of deionized water, and the resulting SiO 2 γ-type spherical alumina with a content of 8%. Its specific surface area is 309m 2 / g, the pore volume is 1.18ml / g, and the bulk density is 0.35g / cm 3 , the average particle size is 2.5mm, and the Na content is 25ppm. The XRD spectrum is shown in curve 3 in FIG. 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com