Five-axle linked tandem and parallel digital control polishing machine tool

A five-axis linkage and machine tool technology, applied in the field of polishing machine tools, can solve problems such as difficult operation, low efficiency, and health hazards of operators, and achieve the effects of easy control, high motion precision, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

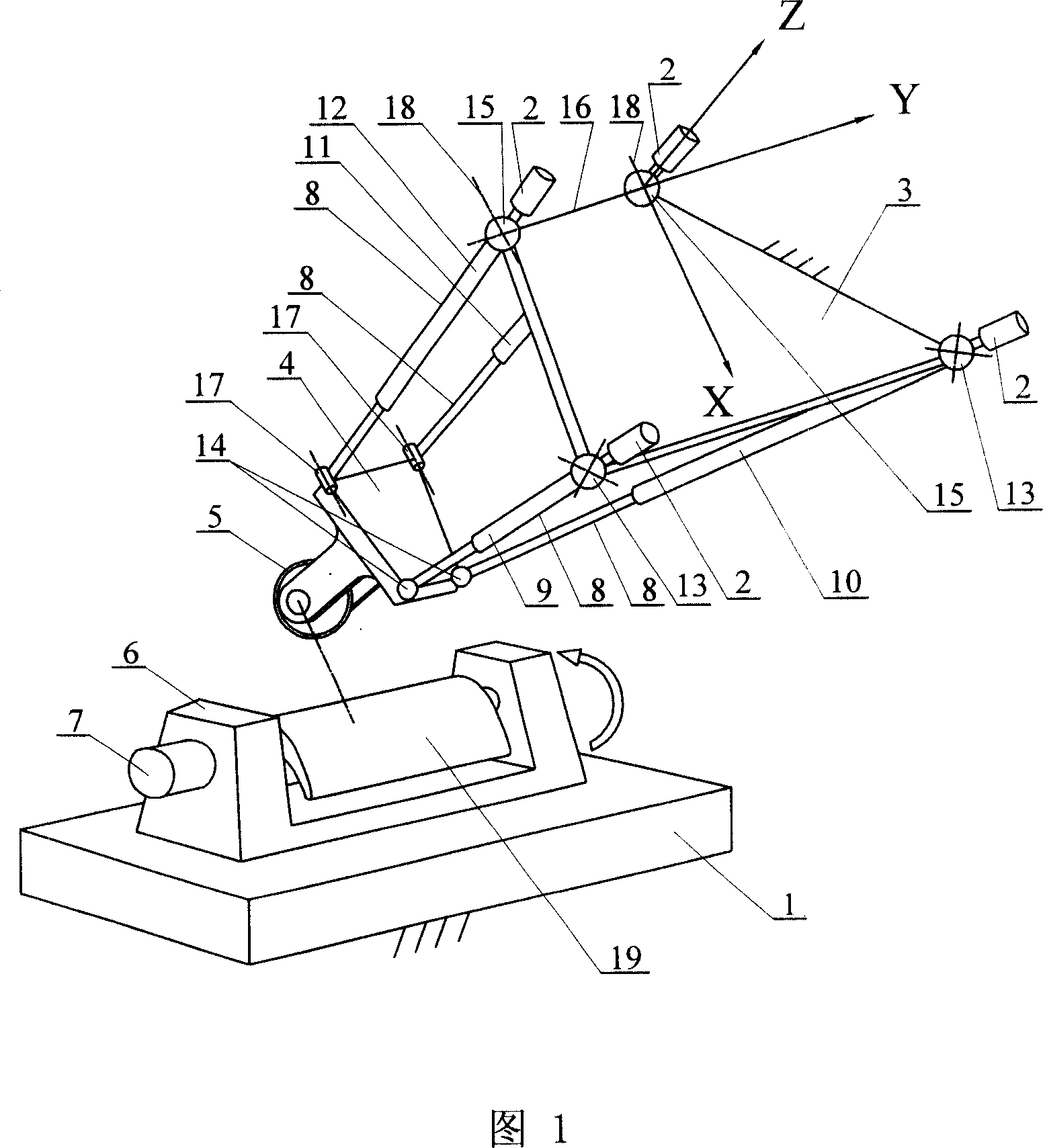

[0009] Embodiment 1: This embodiment is described in conjunction with FIG. 1. This embodiment consists of a fixed table 1, a first servo motor 2, a fixed platform 3, a moving platform 4, a grinding wheel 5, a numerical control turntable 6, a second servo motor 7 and four The fixed platform 3 is located above the moving platform 4, and the moving platform 4 and the fixed platform 3 are connected by four telescopic connecting rods 8, and the upper ends of the four telescopic connecting rods 8 are respectively connected with the first telescopic connecting rod 8. A servo motor 2 is connected by transmission. The grinding wheel 5 is mounted on the support wall at the lower end of the moving platform 4 and is connected to the moving platform 4 in rotation. A fixed workbench 1 is provided directly below the grinding wheel 5. The fixed workbench 1 is equipped with a The numerically controlled turntable 6 driven by the second servo motor 7 .

specific Embodiment approach 2

[0010] Specific Embodiment 2: This embodiment is described in conjunction with FIG. 1. The four telescopic links 8 of this embodiment are composed of a first telescopic link 9, a second telescopic link 10, a third telescopic link 11 and a fourth telescopic link. 12; the upper end of the first telescopic link 9 and the upper end of the second telescopic link 10 are respectively connected to the fixed platform 3 through the first Hooke hinge 13, the lower end of the first telescopic link 9 and the second The lower ends of the two telescopic connecting rods 10 are respectively connected to the moving platform 4 through a ball joint 14, and the upper ends of the third telescopic connecting rod 11 and the upper end of the fourth telescopic connecting rod 12 are respectively connected to the fixed platform through the second Hooke hinge 15. 3 connection, the first-stage rotary axis 16 of the two second Hooke hinges 15 coincides with the Y axis (the establishment of the coordinate sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com