Method for producing oxygen by microwave heated oxygen candle and oxygen candle and microwave device

A microwave heating and microwave device technology, applied in the direction of chloric acid, chlorate, etc., can solve the problems of unstoppable decomposition process, small particle diameter, and large smoke generation, so as to save oxygen, increase oxygen content, and increase production The effect of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

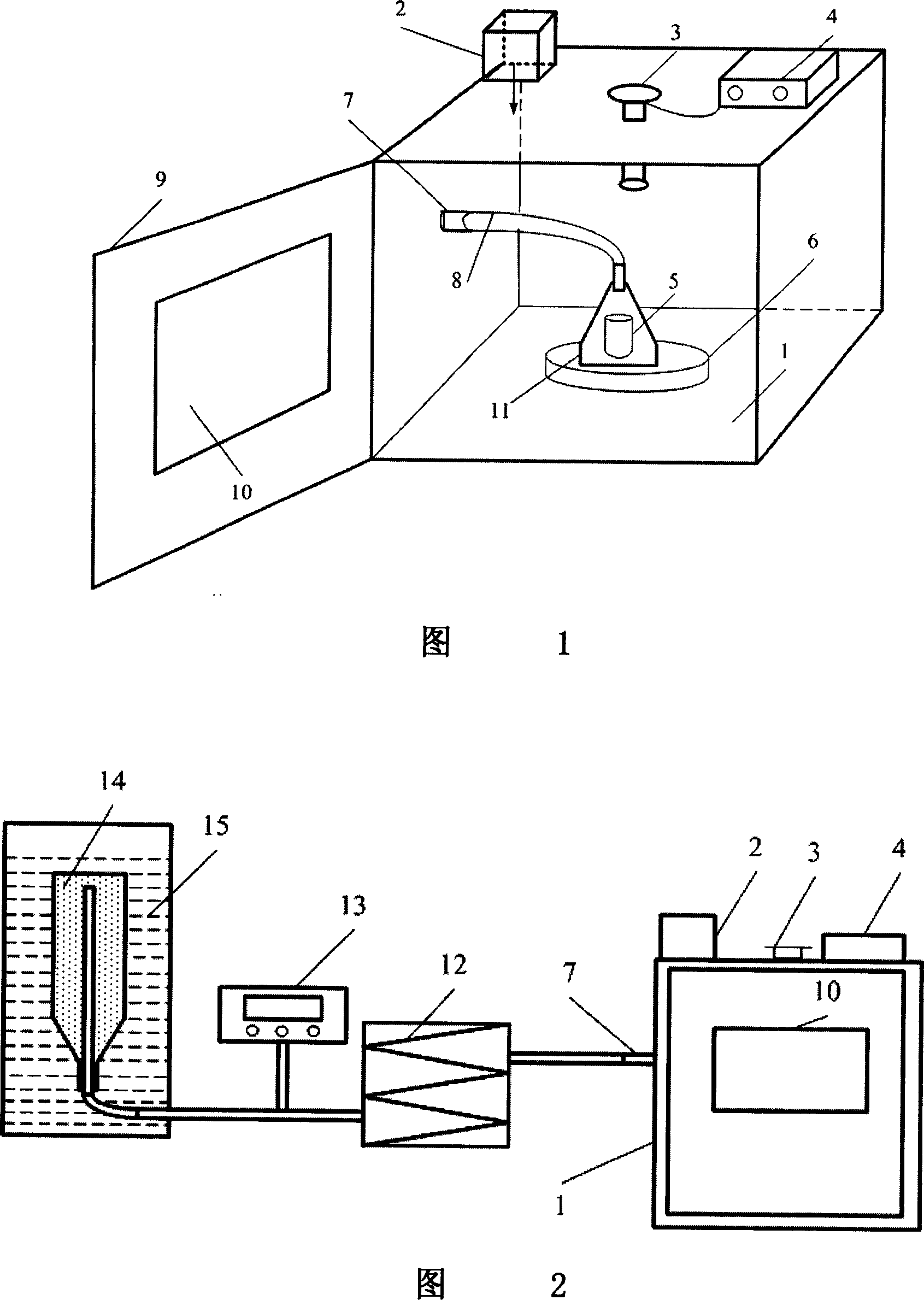

Image

Examples

Embodiment 1

[0050] A microwave device equipped with a microwave tube with a power of 750W (a microwave tube is a device that converts electrical energy into microwave energy. Because of the conversion efficiency, the power of the microwave device is greater than the power of the microwave tube), the microwave frequency is 2450±50MHz; the weight of the oxygen candle is 20g, cylindrical, diameter 25mm, height 25mm, density 1.6g / cm 3 . Oxygen candle formula (weight percent): sodium chlorate (NaClO 3 )86%, barium peroxide (BaO 2 ) 4%, micron copper oxide (CuO) 10%. It takes 81s for the oxygen candle to absorb microwave energy and be heated in the microwave until it undergoes thermal decomposition to produce oxygen.

Embodiment 2

[0052] A microwave device equipped with a microwave tube with a power of 750W, the microwave frequency is 2450±50MHz, the weight of the oxygen candle is 20g, the diameter is 25mm, the height is 25mm, and the density is 1.6g / cm 3 . Oxygen candle formula (weight percent): sodium chlorate (NaClO 3 )80%, barium peroxide 6% (Ba 2 o 2 ), micron copper oxide (CuO) 10%, kaolin 4%. It takes 68 seconds for the oxygen candle to absorb microwave energy and be heated to produce oxygen by thermal decomposition. Apparently, the presence of kaolin as a binder shortens the microwave exposure time.

Embodiment 3

[0054] In order to increase the microwave power, shorten the action time, and make the microwave field intensity of the whole heater uniform, a microwave device with two power 1500W microwave tubes can be set up, the microwave frequency is 2450±50MHz, and the weight of the oxygen candle is 200g. Pressed into cylindrical shape, diameter 50mm, height 50mm, density 2g / cm 3 . Oxygen candle formula (weight percent): sodium chlorate (NaClO 3 ) 89%, nanoscale copper oxide (CuO) 7%, sodium peroxide (Na 2 o 2 )4%. It takes 55 seconds for the oxygen candle to absorb microwave energy and be heated to produce oxygen by thermal decomposition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com