Compositions for reinforcing glass and its reinforcing method

A composition and glass technology, which is applied in the field of composition and strengthening for strengthening glass, can solve the problems such as the strength of ultra-thin glass does not rise but falls, normal cutting cannot be performed, and ITO film is damaged, etc. time, reduced energy consumption, and improved compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

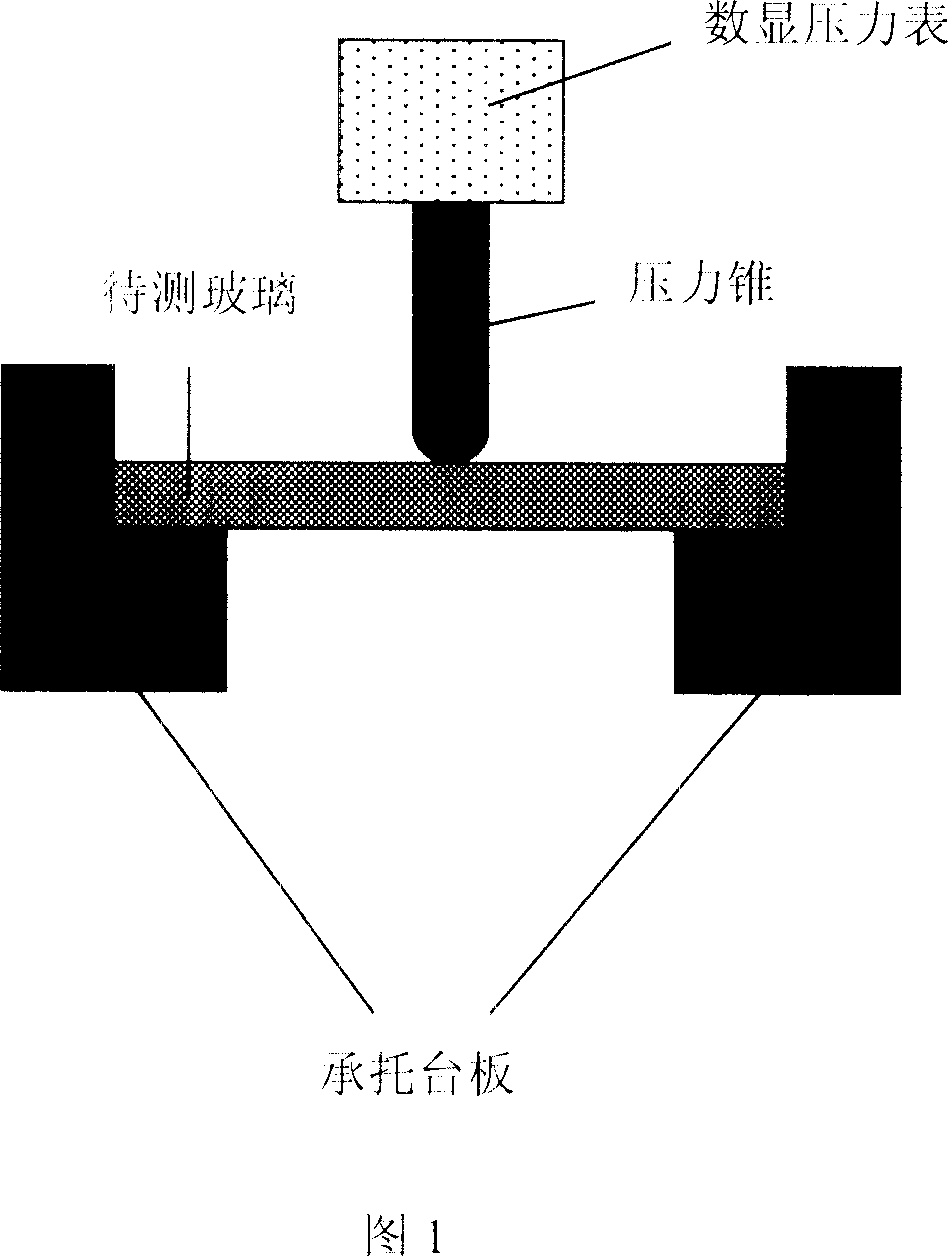

Image

Examples

Embodiment 1

[0023] This example illustrates the strengthening method of ultra-thin silica-coated glass

[0024] Mix 98.5 parts by weight of potassium nitrate, 0.5 parts by weight of potassium phosphate, and 1 part by weight of aluminum oxide. Put this mixture into a molten salt tank with good heat insulation performance, raise the temperature to 480°C at a constant speed under stirring, keep it for 15 minutes, then lower the temperature to 400°C to obtain molten salt.

[0025] Ultra-thin silica-coated glass with a size of 470 × 370 × 0.5 mm (SiO-coated glass produced by Japan Plate Glass Co., Ltd. 2 film, STN substrate glass) was slowly heated to 400°C, and then the ultra-thin silica-coated glass was immersed in the above molten salt for 30 minutes and then taken out, and the molten salt attached to the surface was allowed to flow down naturally, and then heated at 420°C After annealing, cleaning and drying in the annealing chamber, strengthened ultra-thin silica-coated glass B1 is obtaine...

Embodiment 2

[0027] This example illustrates the strengthening method of ultra-thin silica-coated glass

[0028] Mix 99 parts by weight of potassium nitrate, 0.05 parts by weight of potassium phosphate, and 0.05 parts by weight of aluminum oxide. Put this mixture into a molten salt tank with good heat insulation performance, raise the temperature to 460°C at a uniform speed under stirring, keep it for 20 minutes, then lower the temperature to 420°C to obtain molten salt.

[0029] Ultra-thin silica-coated glass with a size of 470×370×0.5 (SiO-coated glass produced by Japan Plate Glass Co., Ltd. 2 film, STN substrate glass) was slowly heated to 420°C, and then the ultra-thin silica-coated glass was immersed in the above molten salt for 60 minutes and then taken out, and the molten salt attached to the surface was allowed to flow down naturally, and then heated at 400°C Perform annealing in the annealing chamber, clean and dry to obtain strengthened ultra-thin silica-coated glass B2.

Embodiment 3

[0031] This example illustrates the strengthening method of ultra-thin silica-coated glass

[0032] Mix 95 parts by weight of potassium nitrate, 2.0 parts by weight of potassium phosphate, and 3.0 parts by weight of aluminum oxide. Put this mixture into a molten salt tank with good heat insulation performance, raise the temperature to 440°C at a constant speed under stirring, keep it for 10 minutes, then lower the temperature to 390°C to obtain molten salt.

[0033] Ultra-thin silica-coated glass with a size of 470×370×0.5 (SiO-coated glass produced by Japan Plate Glass Co., Ltd. 2 film, STN substrate glass) was slowly heated to 390°C, and then the ultra-thin silica-coated glass was immersed in the above-mentioned molten salt for 60 minutes and then taken out, and the molten salt attached to the surface was allowed to flow down naturally, and then heated at 420°C Perform annealing in the annealing chamber, clean and dry to obtain strengthened ultra-thin silica-coated glass B3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com