Superhigh molecular polyethylene compound pipe and method for manufacturing same

A polyethylene composite pipe, ultra-high molecular weight technology, applied in chemical instruments and methods, pipes/pipe joints/fittings, pipes, etc., can solve the problems of large investment in plant construction, high technical difficulty, and influence on popularization and application. Achieve the effect of less investment, less technical difficulty and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

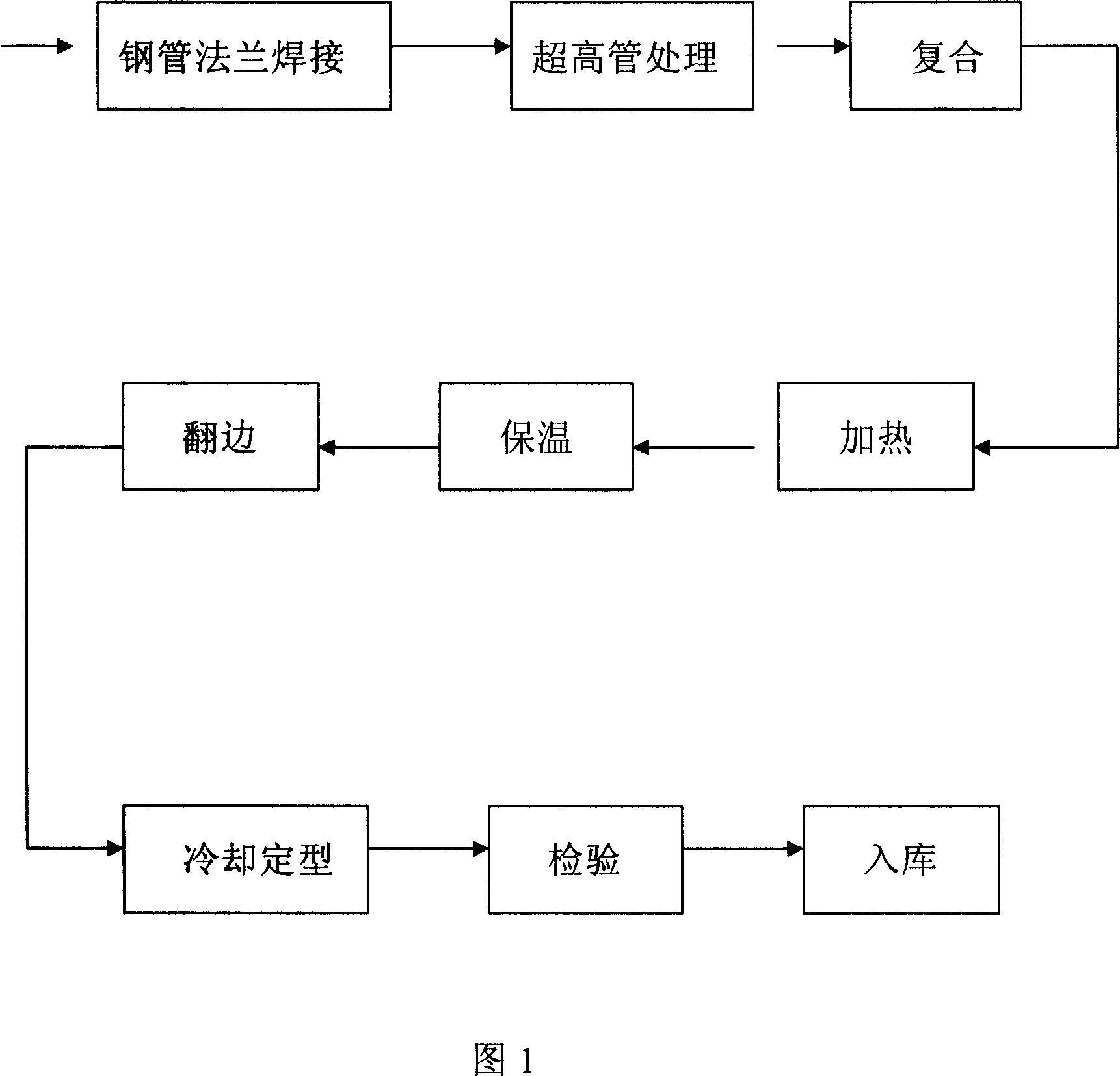

[0020] The technical process of the present invention is described in detail in conjunction with the accompanying drawings.

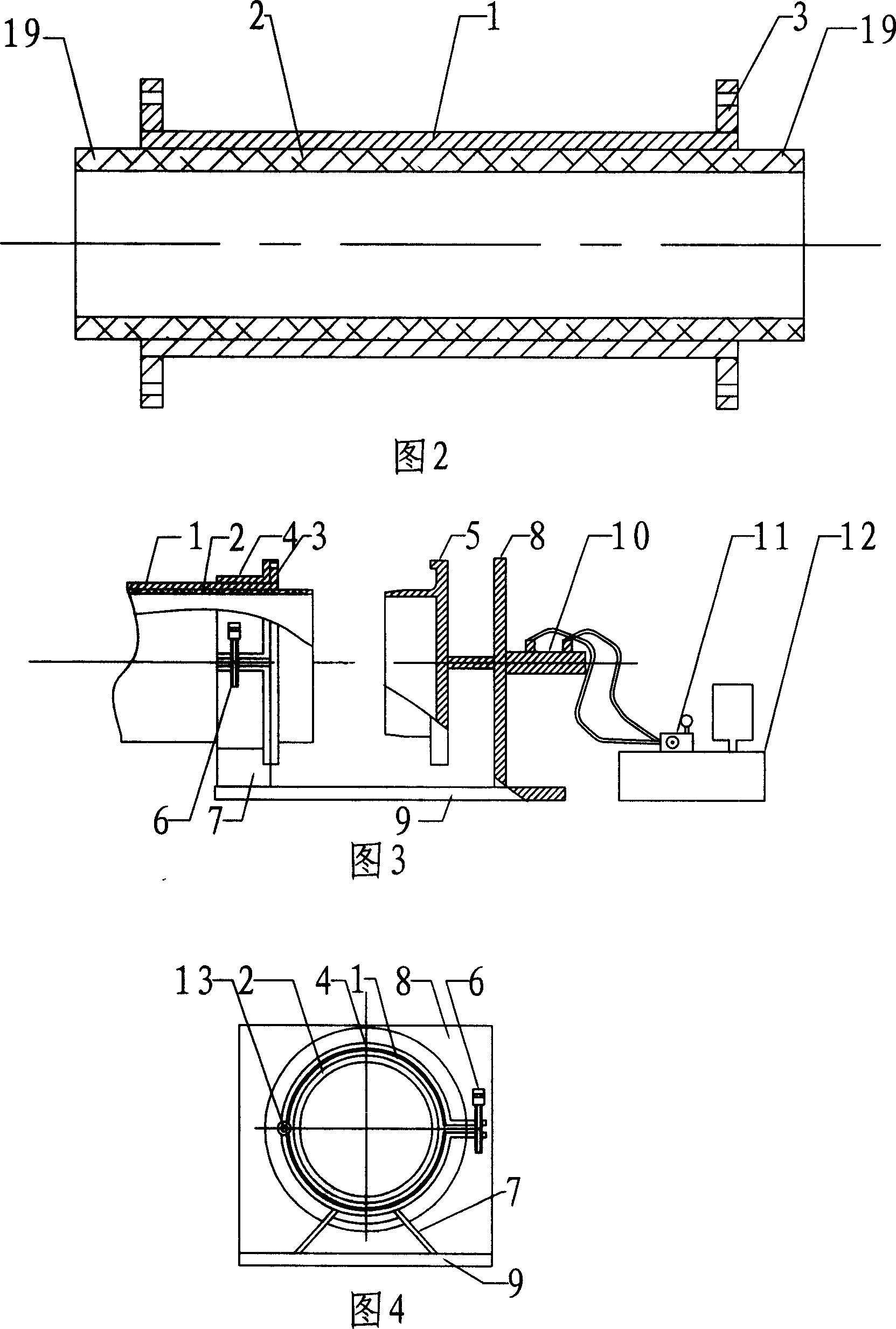

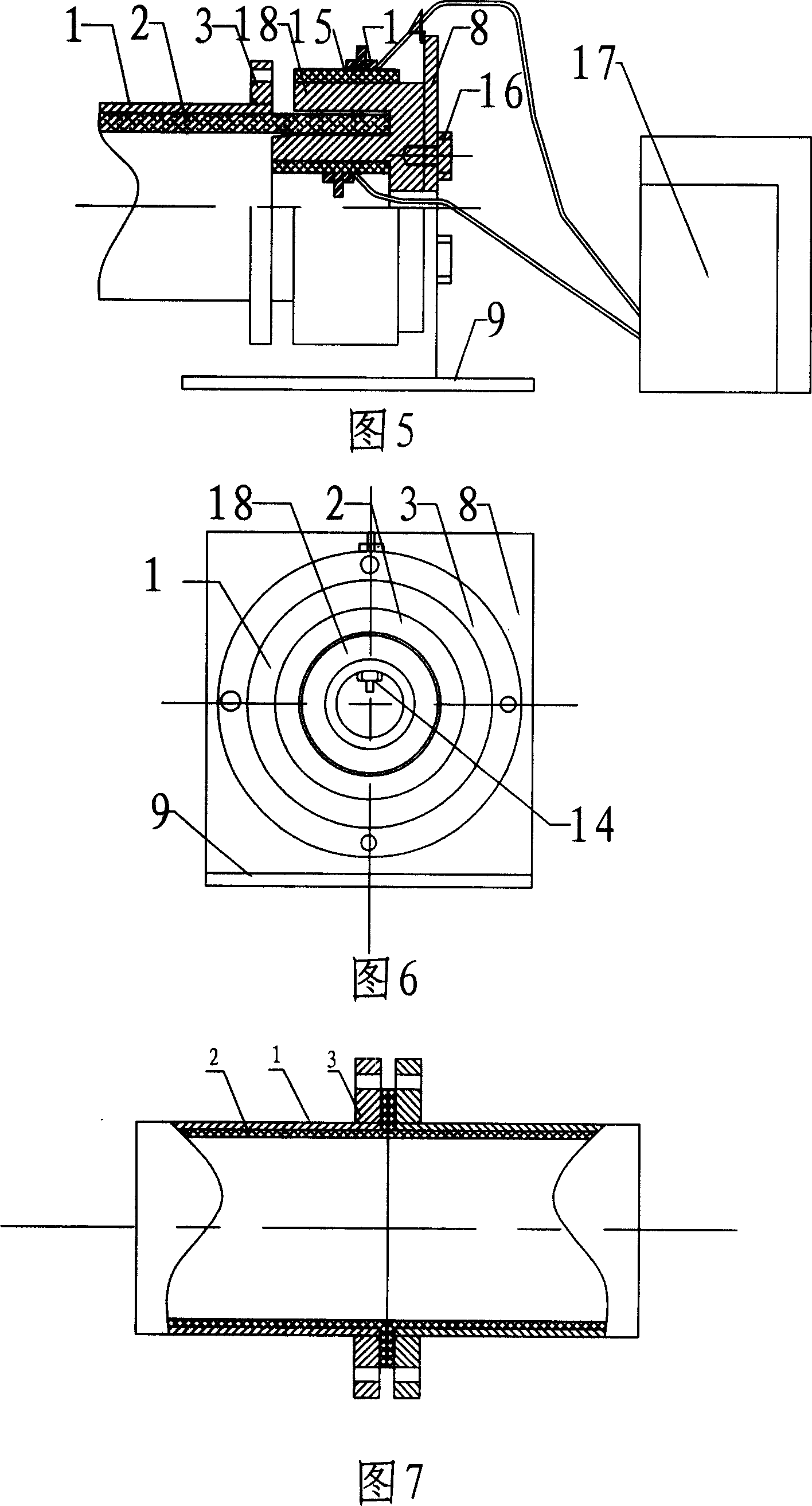

[0021] An ultra-high molecular weight polyethylene composite pipe, which is characterized in that it is composed of an ultra-high molecular weight polyethylene pipe 2 as the inner layer of the base pipe and an outer layer composed of a steel pipe 1 with a flange 3, and a gap is used between the inner layer and the outer layer Cooperate, the ultra-high molecular weight polyethylene pipe matrix pipe material of the inner layer at both ends of the composite pipe is turned out and bonded with the flange to form a connection sealing surface.

[0022] The inner and outer layers adopt clearance fit, and the clearance is between 1-1.5mm.

[0023] The ultra-high-molecular-weight polyethylene composite pipe is characterized in that the ultra-high-molecular-weight polyethylene pipe is lined with steel pipes by composite equipment, and the ultra-high-molecular-weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com