Method and apparatus for testing water ratio of corn

A technology of moisture content and grain, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of inaccurate measurement of grain moisture content, large detection error, etc., and achieve simple device, convenient operation, and wide testing range big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the examples, but the embodiments of the present invention are not limited thereto.

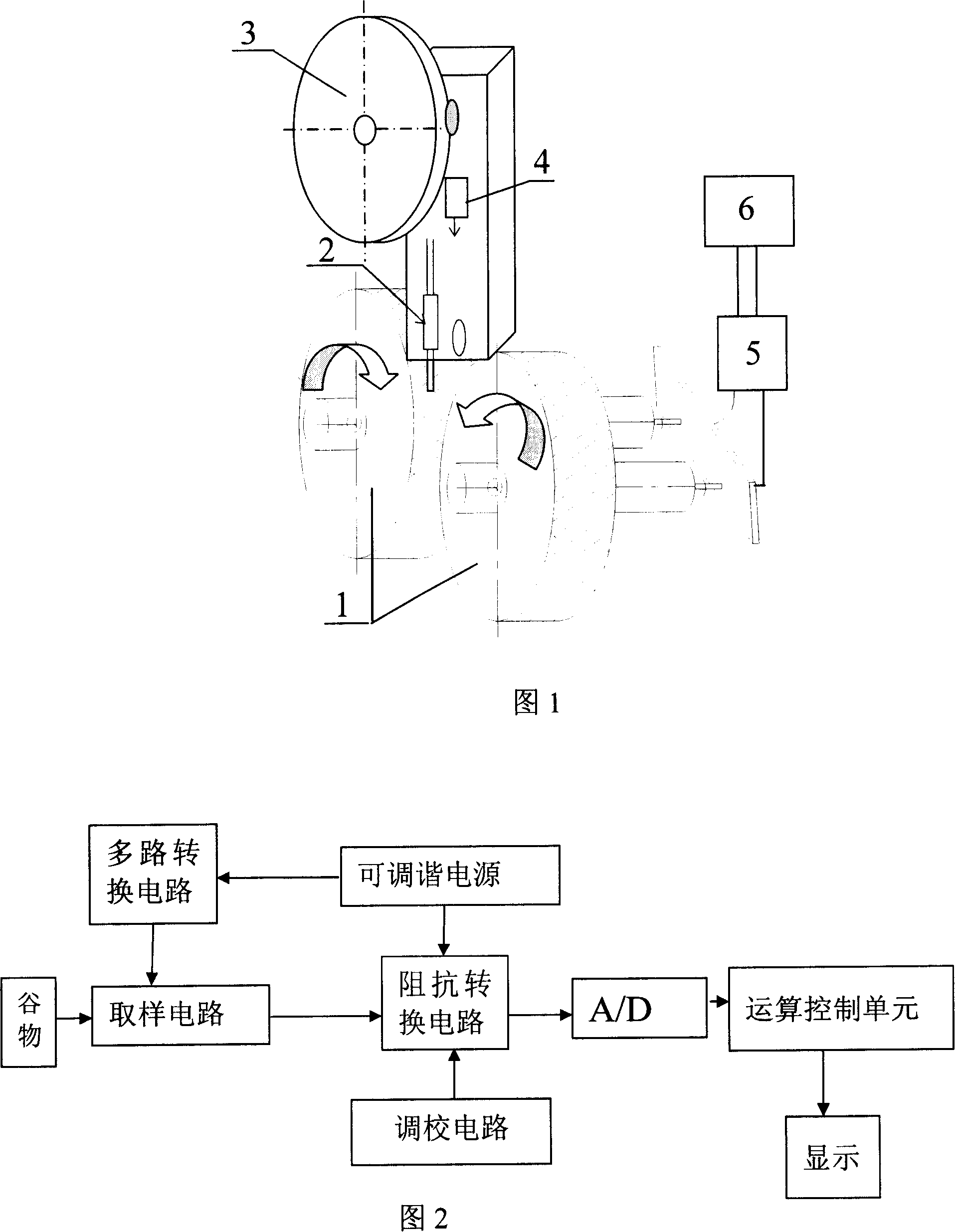

[0033]The end surface of the feeding disc 3 is provided with a seed-receiving groove, and the feeding disc rotates in the longitudinal section during detection, and the grains are sent to the two pressure roller sensors 1 one by one by the seed-receiving grooves evenly distributed on the outer end surface of the feeding disc. between.

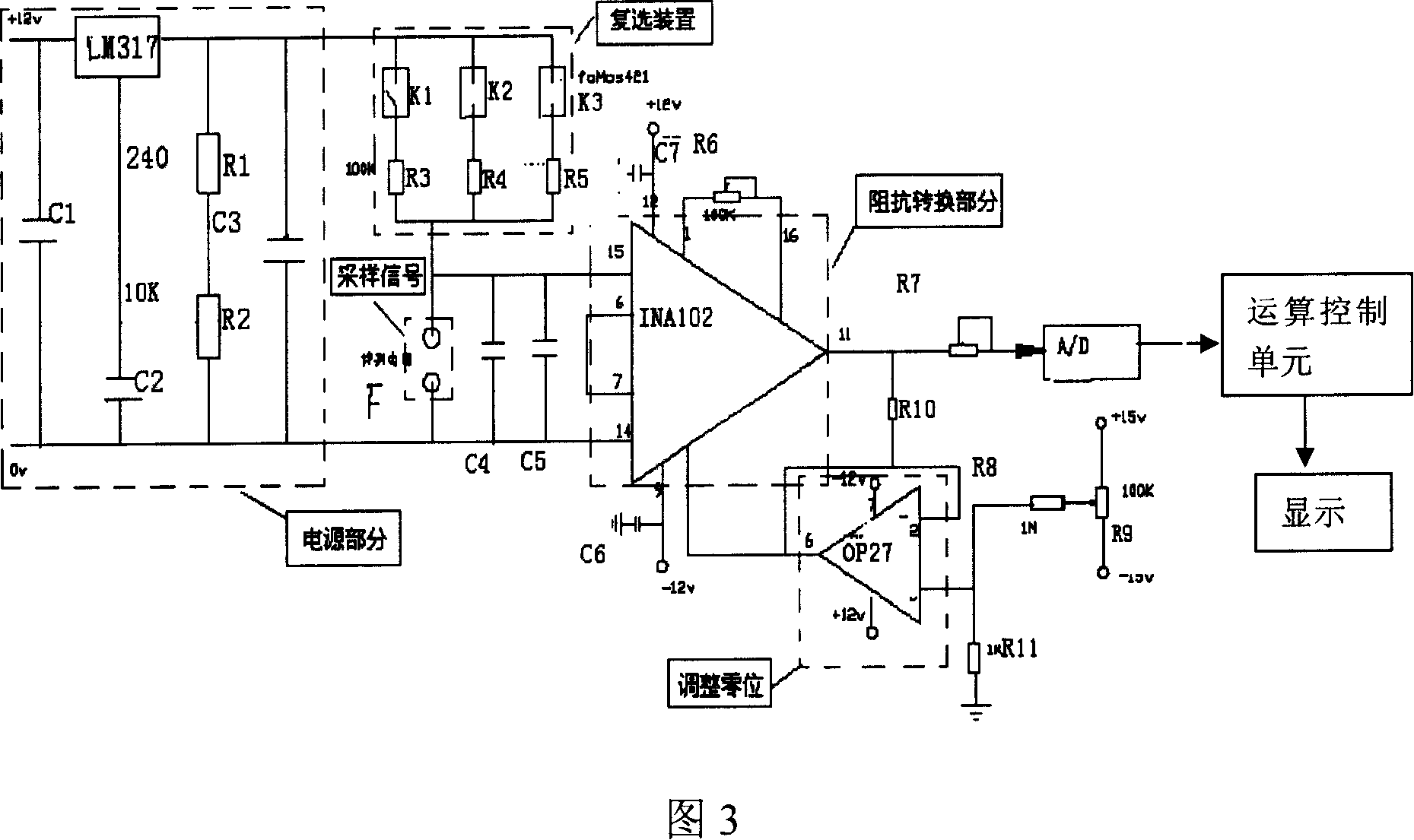

[0034] As shown in Figure 1, the pressure roller sensor 1 is a pair of cylindrical rollers processed from stainless steel. During the measurement, the two pressure roller sensors 1 rotate inwardly, and the two pressure roller sensors are two electrodes, and the potential difference applied thereon is V = R X R i + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com