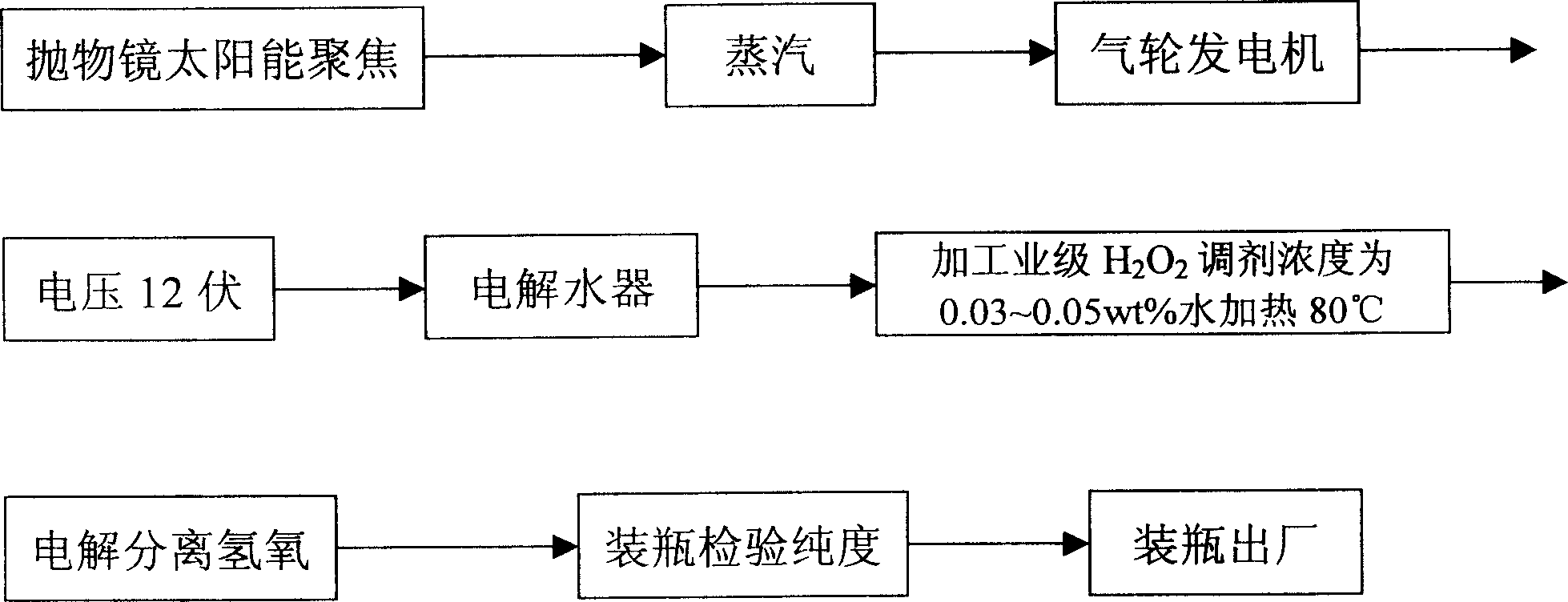

Solar hydrogen making process

A technology of solar energy and solar collectors, applied in energy input, cells, electrolysis process, etc., can solve the problems of low efficiency, large investment, and no large-scale production, and achieve the effect of small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A 20-square-meter daylighting surface parabolic mirror is used to focus the heat-collecting plate to achieve focusing and improve heat energy conversion, so that the water in the pipeline quickly reaches 100°C to generate steam. The exhaust steam pushes the gas turbine generator to rotate, so that the generator speed reaches 2500-3000 revolutions per minute (the generator is made of an automobile generator with air-filled impeller). The voltage is 12 volts, and the power generation per hour is 1kw. Connect the positive and negative poles of the generator to the positive and negative poles of the 150A battery to store electric energy, and the battery supplies power to the WP-1 electrolytic water device to electrolyze the water to separate hydrogen and oxygen, and then add excess steam to the positive and negative water pipes of the electrolytic water device , add industrial grade hydrogen peroxide, adjust the concentration of water in the electrolyzer to 0.05%, make the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com