Heat treatment jig for silicon semiconductor substrate

一种硅基板、半导体的技术,应用在处理舟使用的领域,能够解决设备成品率降低等问题,达到维持品质特性、降低平滑裂隙、消除表面阶梯差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

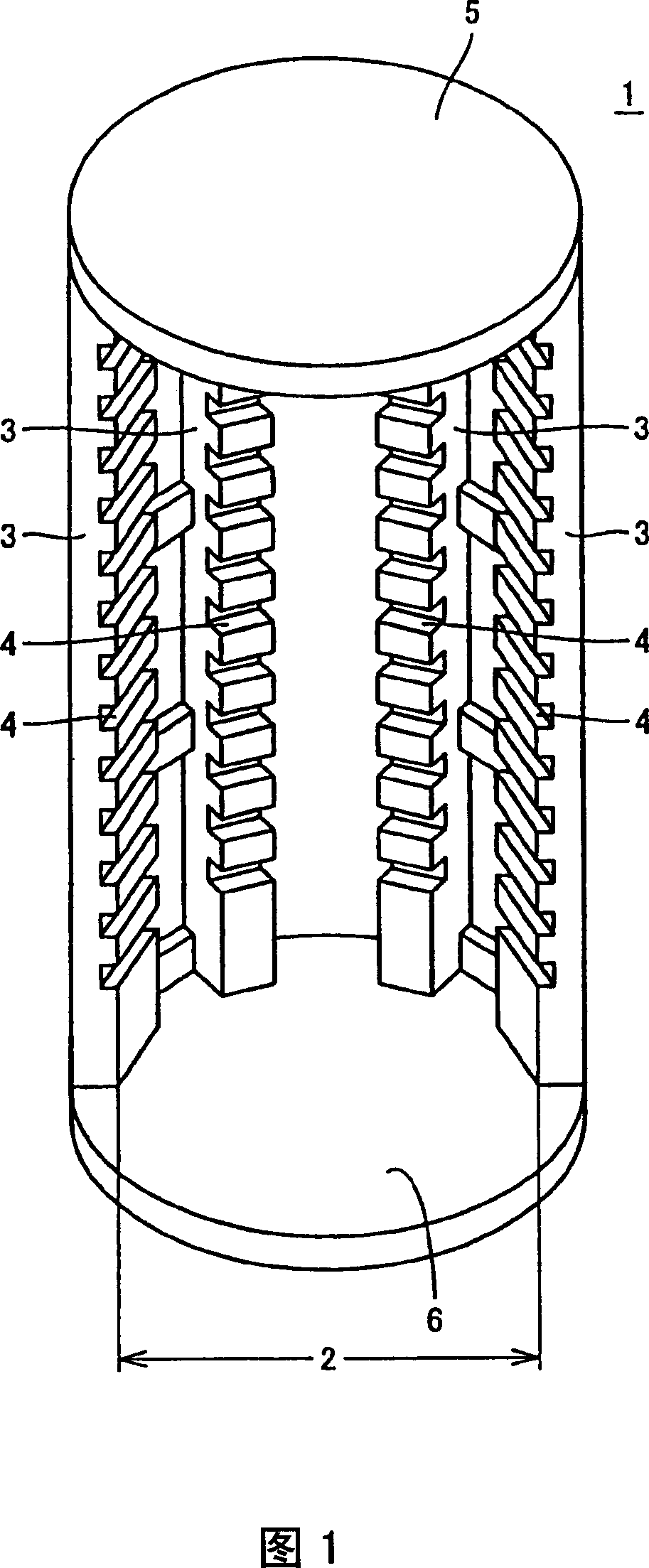

[0080] In order to confirm whether the thickness of the jig is appropriate, as the jig of Invention Example No. 1, three silicon carbide (SiC) circular plate structure heat treatment jigs with a diameter of 319 mm, a thickness of 1.5 mm, and a deflection displacement It is 40 μm to 60 μm, and the surface roughness is 1.5 μm to 1.7 μm.

[0081] Similarly, as the jig of Comparative Example No. 1, three SiC heat treatment jigs with a disc structure of 319 mm in diameter, 0.9 mm in thickness, 50 μm to 80 μm in deflection displacement, and surface roughness 1.4 μm to 1.7 μm.

[0082] A silicon substrate with a diameter of 300mm is loaded on these heat treatment jigs, and the temperature is raised from 600°C to 1000°C at a rate of 5°C / min in an argon atmosphere in a vertical heat treatment furnace at a rate of 3°C / min. Raise the temperature to 1200°C and keep it at 1200°C for one hour, then cool down to 600°C at a rate of 3°C / min. The silicon substrate after heat treatment was obs...

Embodiment 2

[0086] As the jig of Invention Example No. 2, fifty SiC disc-shaped heat treatment jigs with a diameter of 319 mm, a thickness of 2.0 mm, a deflection displacement of 30 μm to 60 μm, and a surface roughness of 1.5 μm~2.0μm.

[0087] The same heat treatment as in Example 1 was performed after mounting the obtained jigs of Invention Example No. 2 on a vertical heat treatment boat at a pitch of 12 mm. The silicon substrate after heat treatment was observed with a magic mirror device for smooth cracks. As a result, most of the silicon substrates had smooth cracks on the outer periphery.

[0088] Next, after mounting the same jigs of Invention Example No. 2 on a vertical heat treatment boat at a pitch of 12 mm, heat treatment was carried out under the same conditions as above, but the heating and cooling rate from 1000°C to 1200°C was changed to 1.5°C / minute. Observation of the silicon substrate after the heat treatment revealed that smooth cracks formed in the outer peripheral ...

Embodiment 3

[0092] Furthermore, jigs of Invention Examples Nos. 4 to 6 described below were produced using the remaining material subjected to the opening processing in the above-mentioned Example 2.

[0093] First, as the jig of Invention Example No. 4, ten heat treatment jigs with a circular plate structure made of SiC with a diameter of 210 mm, a thickness of 1.8 mm, a deflection displacement of 30 μm to 60 μm, and a surface roughness of 2.1 μm ~ 2.3 μm.

[0094] Next, as the jig of Invention Example No. 5, ten heat treatment jigs with a ring structure made of SiC having a diameter of 210 mm, an inner diameter of 205 mm, a thickness of 1.8 mm, a deflection displacement of 30 μm to 60 μm, and a surface The roughness is 2.1 μm to 2.2 μm.

[0095] Furthermore, as the jig of Invention Example No. 6, ten heat treatment jigs with a ring structure made of SiC having a diameter of 210 mm, an inner diameter of 200 mm, a thickness of 1.8 mm, a deflection displacement of 30 μm to 60 μm, and a su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com