Novel oxonol dye compound and optical information recording medium

An optical recording medium and recording medium technology, applied in the direction of optical recording carrier, recording/reproducing by optical methods, organic dyes, etc., can solve the problems of undisclosed combination of oxonol dyes and azo dyes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0453]Specific examples are described in JP-A-58-175693, JP-A-59-81194, JP-A-60-18387, JP-A-60-19586, JP-A-60-19587, JP-A-60- 35054, JP-A-60-36190, JP-A-60-36191, JP-A-60-44554, JP-A-60-44555, JP-A-60-44389, JP-A-60-44390, JP-A-60-54892, JP-A-60-47069, JP-A-63-209995, JP-A-4-25492, JP-B-1-38680, JP-B-6-26028, German Patent 350, 399 and Nippon Kagaku-kai Shi, October, pp. 1141 (1992).

[0454] The amount of the decolorization inhibitor, for example, a single acid quencher, is usually 0.1 to 50% by mass, preferably 0.5 to 45% by mass, more preferably 3 to 40% by mass, particularly preferably 5 to 25% by mass.

[0455] [reflective layer]

[0456] On the recording layer, a reflective layer is arranged to increase the reflectivity when information is reproduced. The reflective material used as the material for the reflective layer is a material with high laser reflectivity, examples of which include metals or semi-metals such as Mg, Se, Y, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, W , Mn...

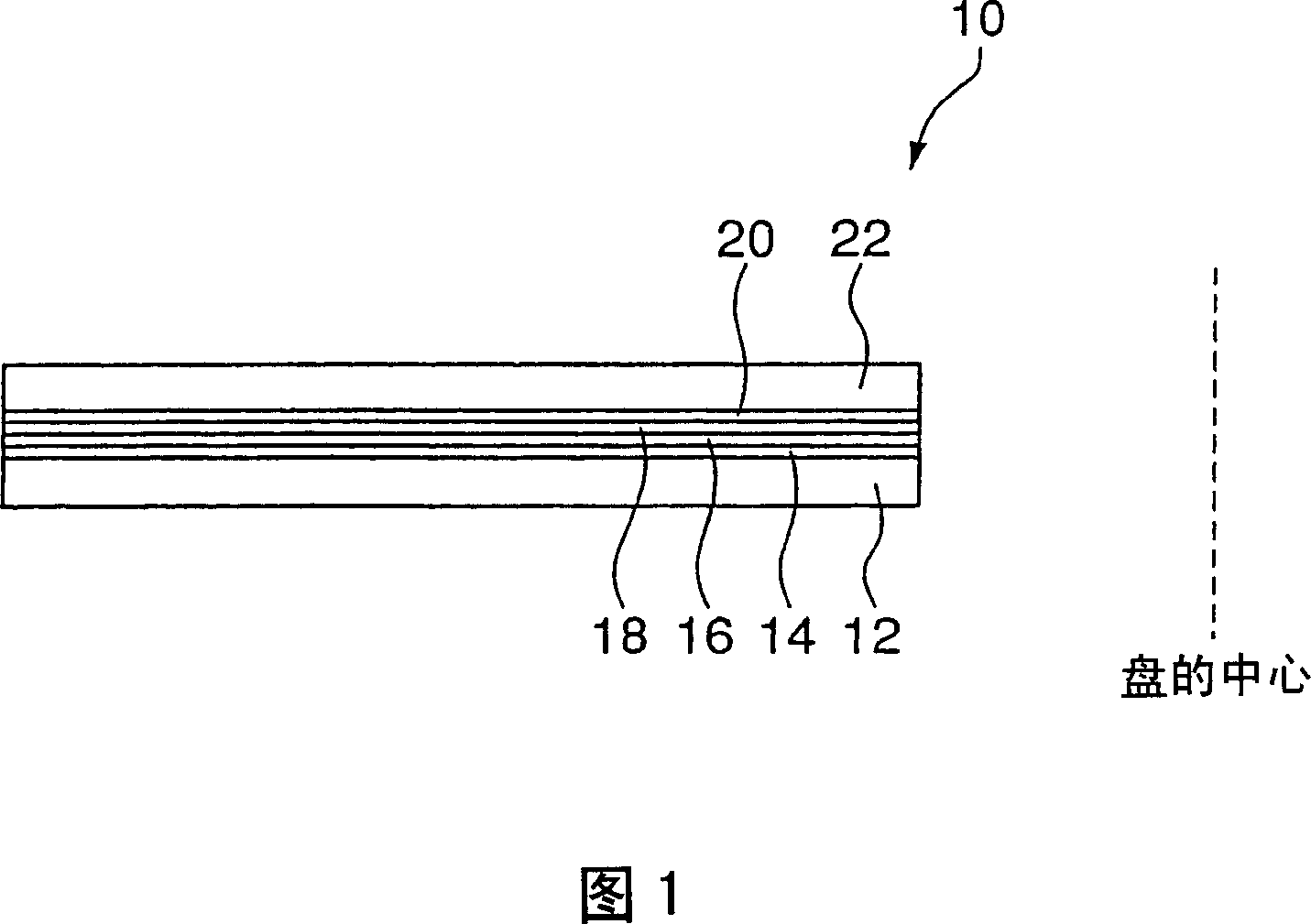

Embodiment 1

[0481] A substrate having a thickness of 0.6 mm and a diameter of 120 mm having a spiral groove (depth: 120 nm, width: 350 nm, track pitch: 0.74 μm) was formed by injection molding with polycarbonate resin. 0.95 g of dye A shown below and 0.05 g of dye B shown below were dissolved in 100 ml of 2,2,3,3-tetrafluoropropanol to prepare a coating solution, and the resulting coating solution was passed through a spinner Coating is applied on the surface of the above-mentioned substrate on the side where the grooves are formed, thereby forming a recording layer.

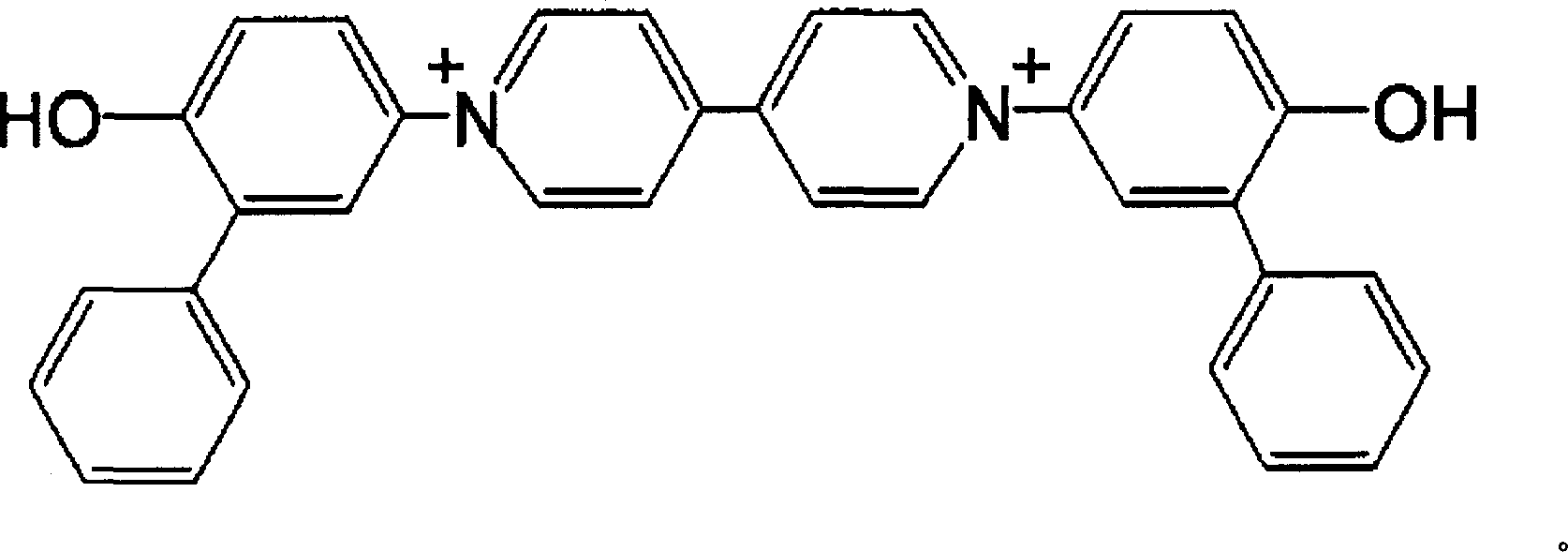

[0482] Dye A

[0483]

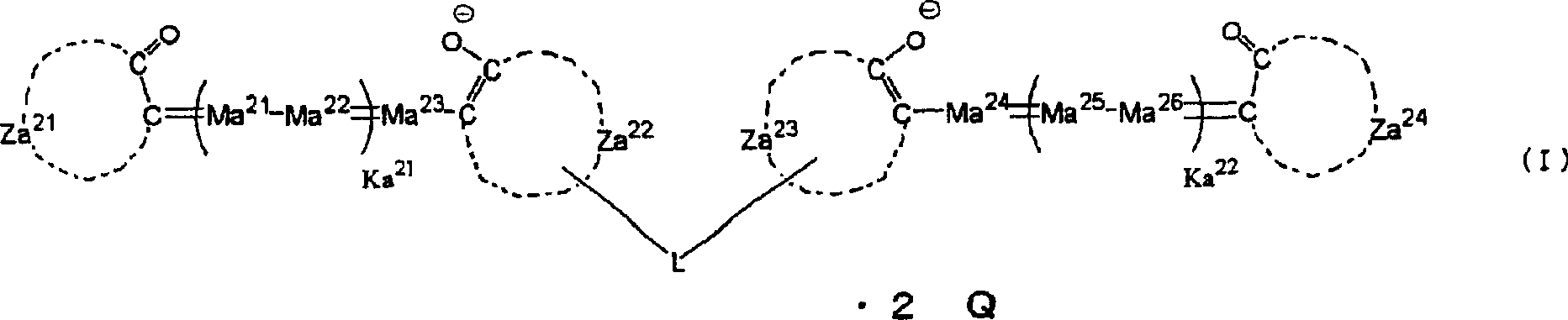

[0484] Dye B

[0485]

[0486] Thereafter, silver was sputtered on the dye-coated surface to form a reflective layer with a thickness of about 120 nm, and then the substrate was adhered to a dummy substrate of the same size as the above substrate using a UV curable resin as an adhesive on, thereby making each DVD-R disk (optical recording medium).

Embodiment 1-1

[0507] Evaluation of Spin Coating Suitability :

[0508] The dye (total amount 0.2 g) mixed in the ratio shown in Table 1 was dissolved in 10 ml of 2,2,3,3-tetrafluoropropanol, spin-coated on a polycarbonate substrate, and then checked by visual observation Coating streaks are present.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com