Substrate conveying system, substrate conveying device and substrate treatment device

A substrate conveying and substrate technology, which is applied in glass transportation equipment, glass manufacturing equipment, glass production, etc., can solve the problems of resist coating film thickness variation, coating gap variation, increasing the deflection of the conveying arm, etc. To achieve the effect of suppressing uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

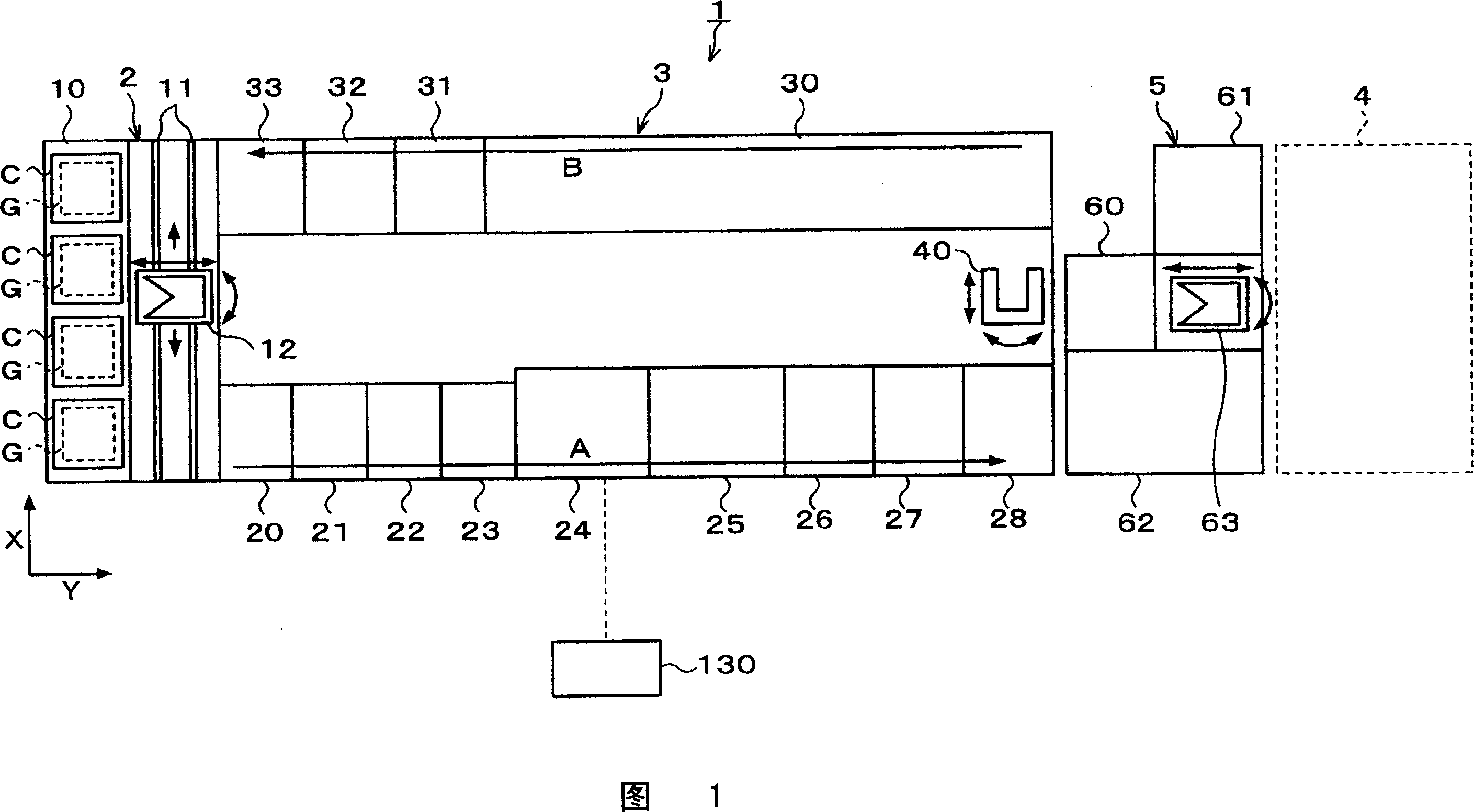

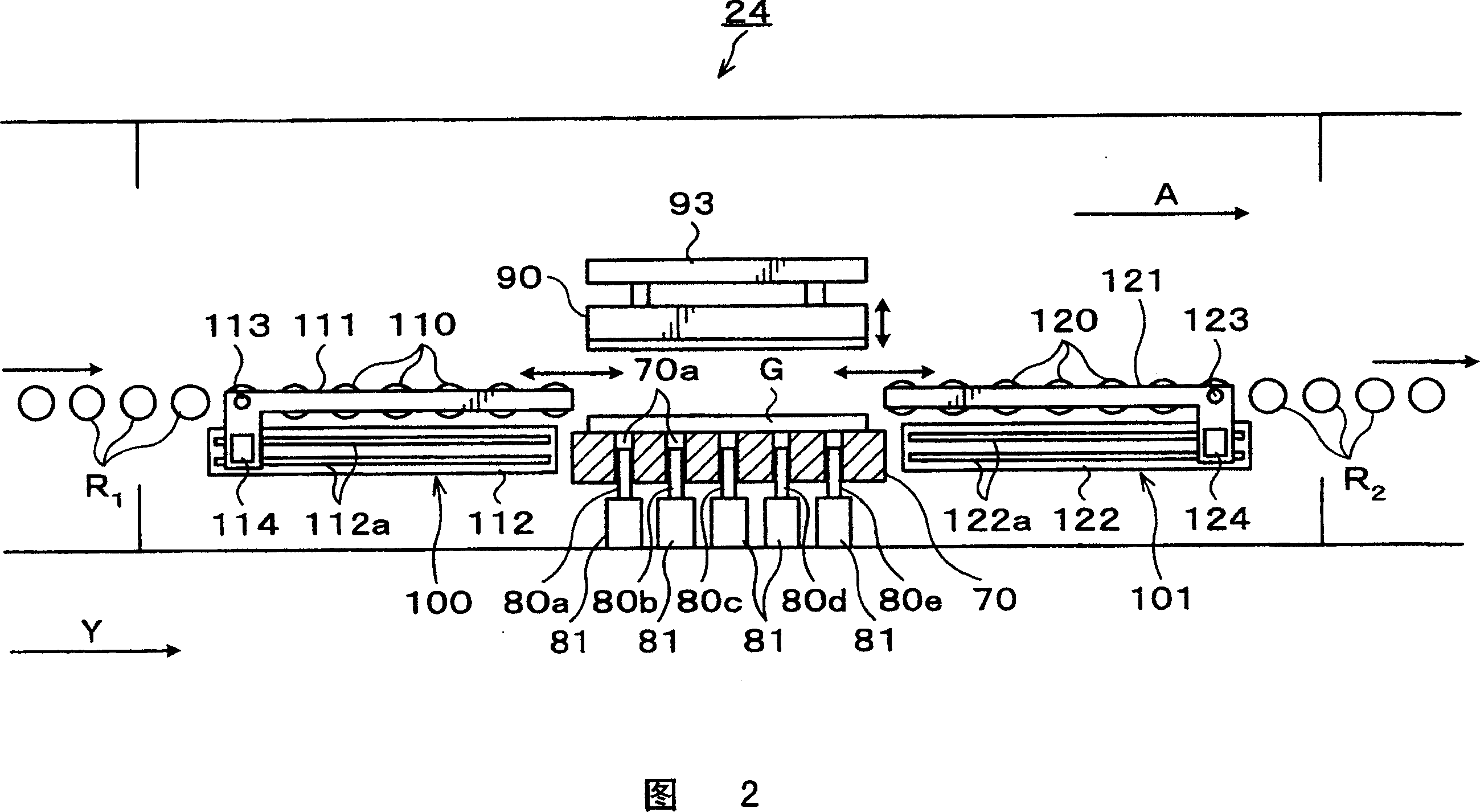

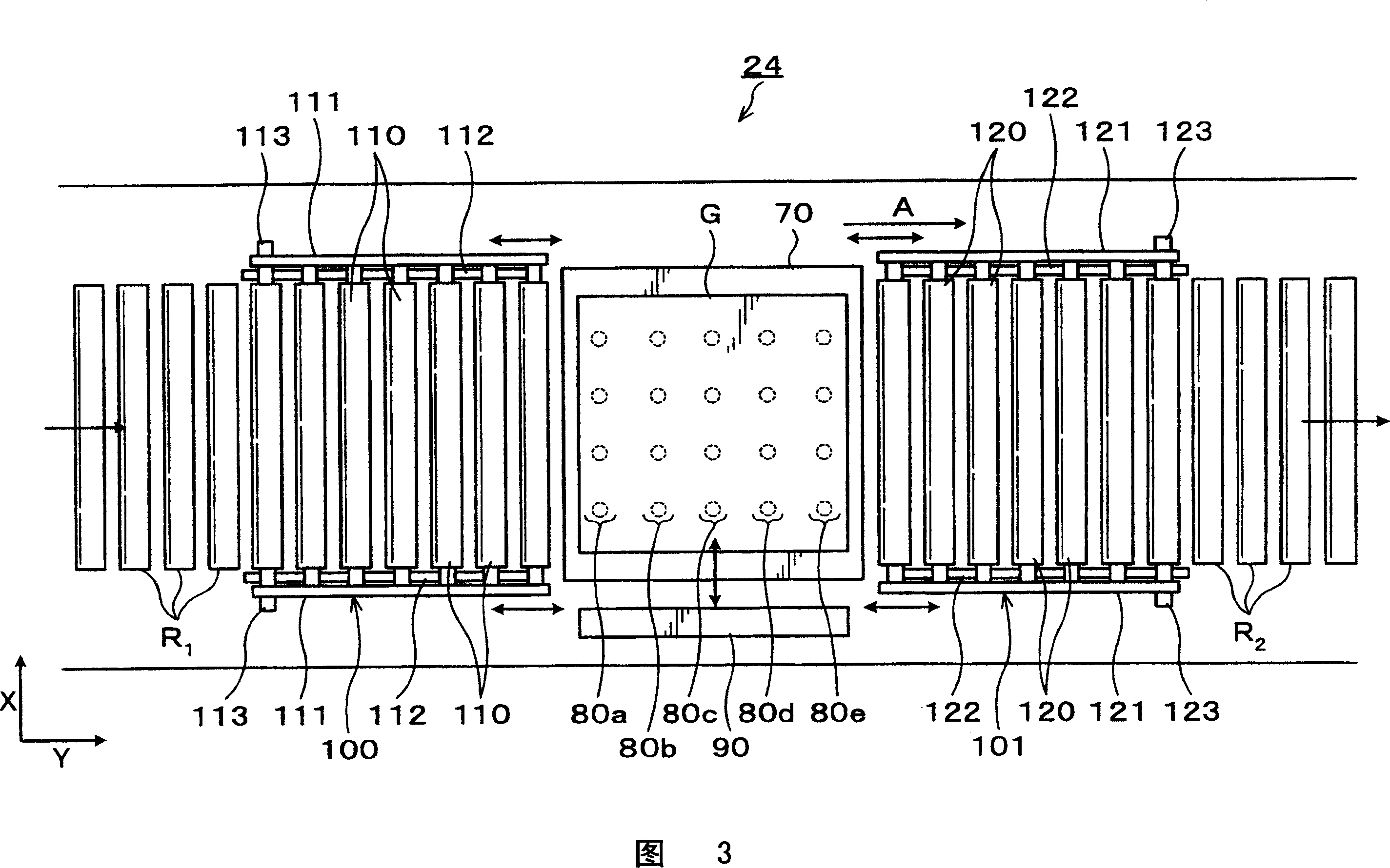

[0073] Hereinafter, preferred embodiments of the present invention will be described. FIG. 1 is a plan view schematically showing the configuration of a coating and development processing apparatus 1 equipped with a substrate conveyance system according to the present embodiment.

[0074] As shown in FIG. 1, the coating and development processing apparatus 1 has, for example, a cassette station 2 for loading and unloading a plurality of glass substrates G to the outside in units of cassettes, and is equipped with a predetermined substrate for carrying out a predetermined process in a single sheet in the photolithography process. The structure in which the processing station 3 of various processing components of the processing and the interface station 5 that is adjacent to the processing station 3 and performs transfer of the glass substrate G between the processing station 3 and the exposure device 4 are integrally connected.

[0075] The cassette station 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com