Heat-pipe performance detecting apparatus

A detection device, heat pipe technology, applied in the direction of material thermal development, material thermal conductivity, etc., can solve the problems of heat dissipation and temperature measurement variation, unfavorable heat pipe, long-term and frequent reuse, etc., to achieve good consistency and Reproducible, shift-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

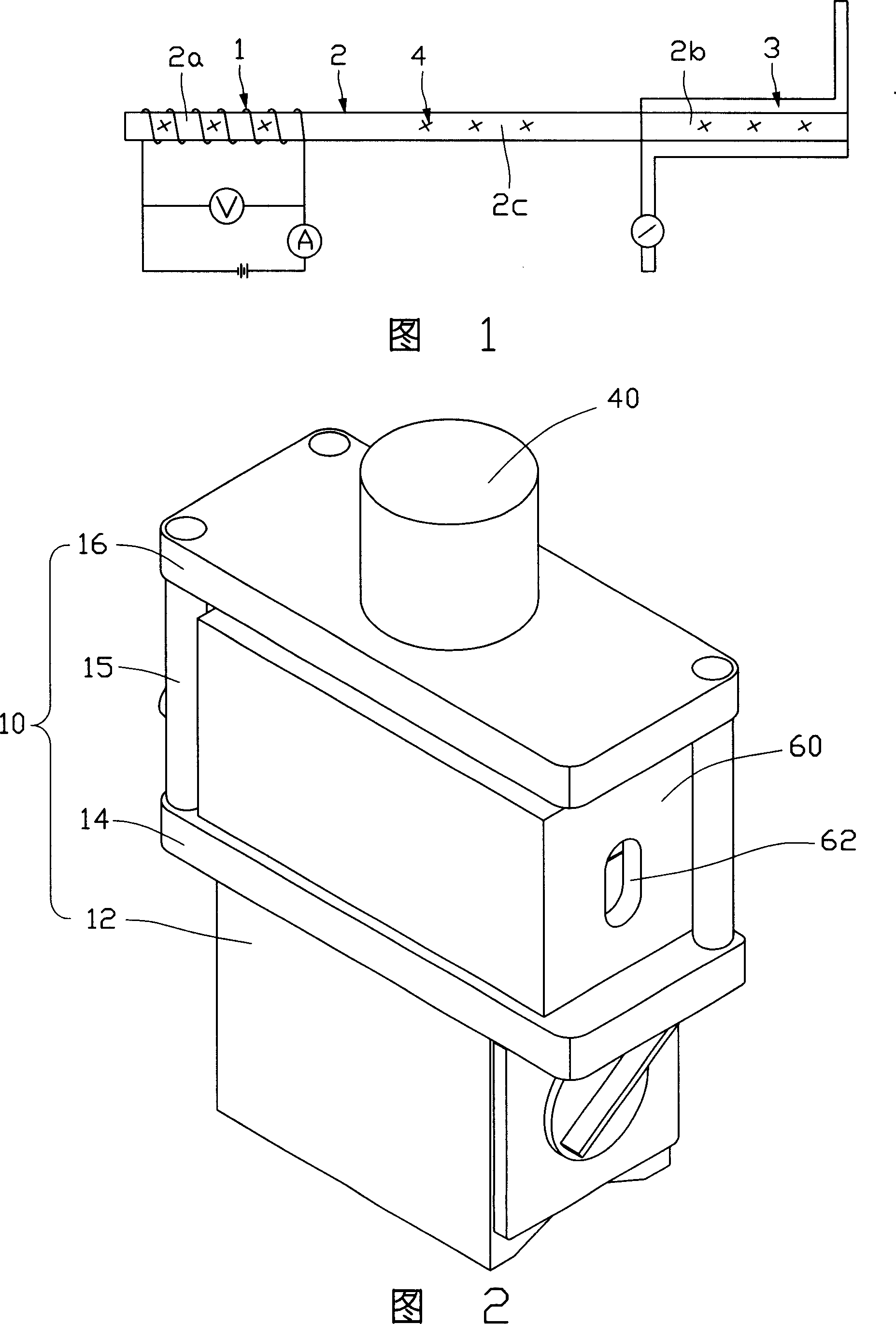

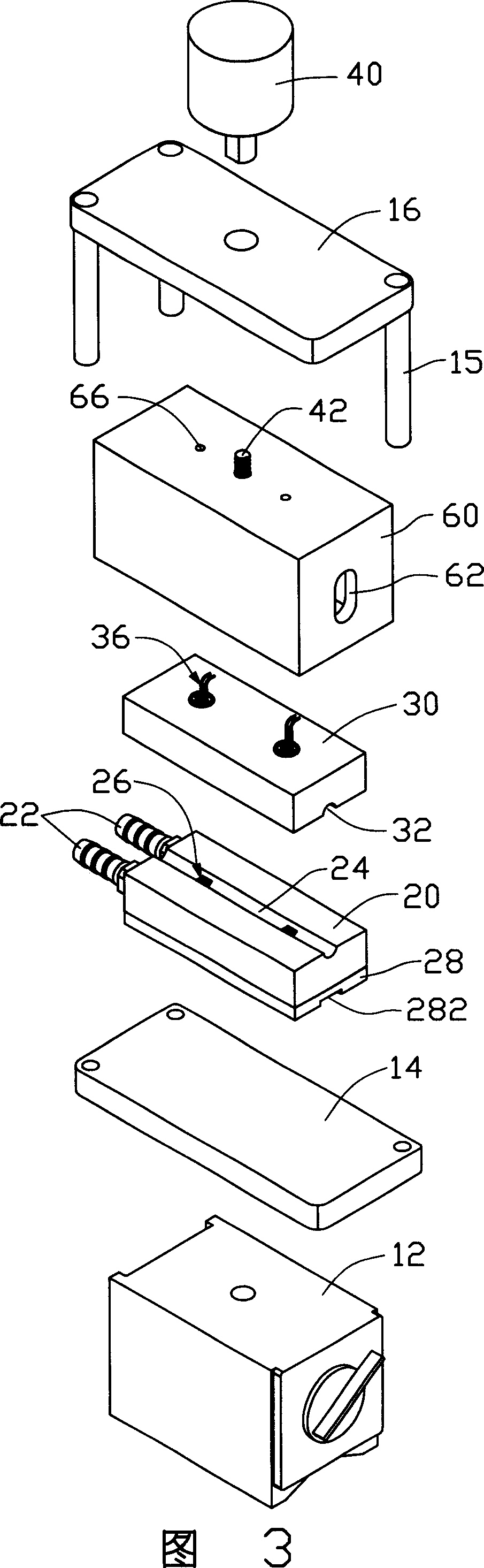

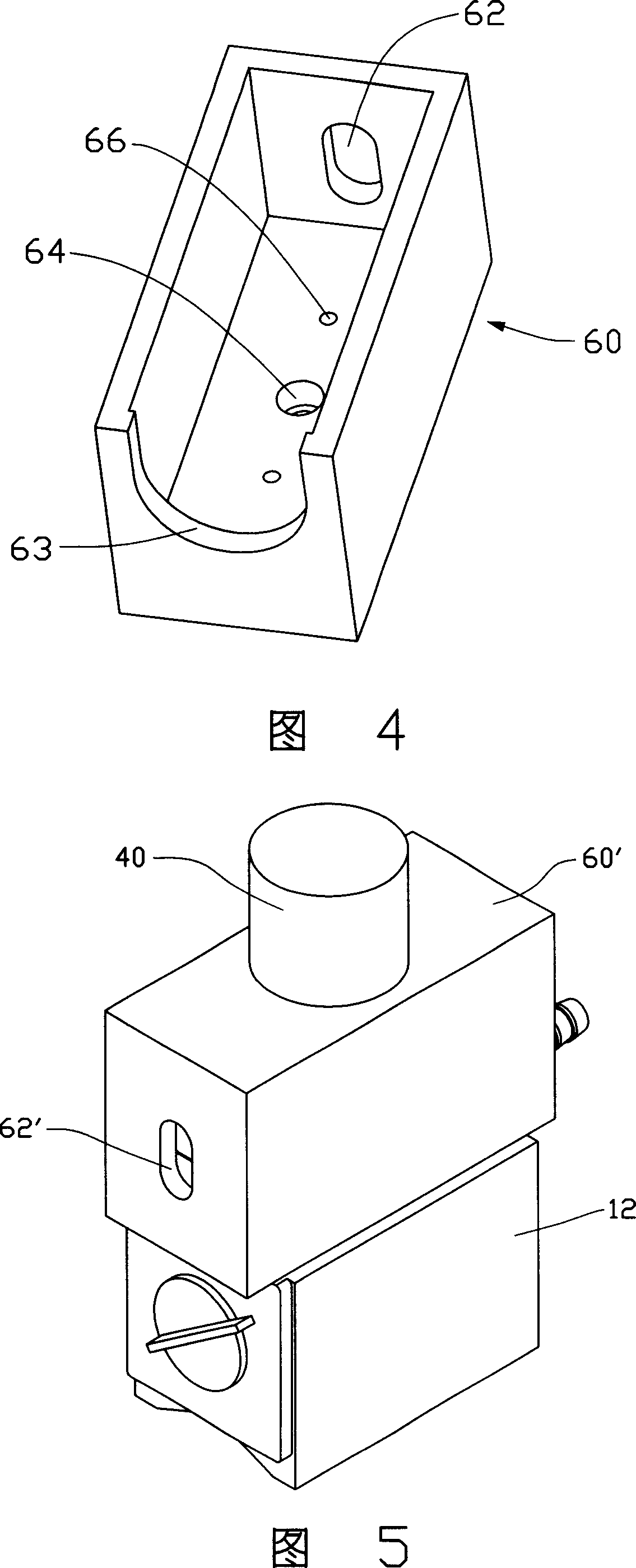

[0022] Hereinafter, referring to FIGS. 2 to 6, the heat pipe performance detection device of the present invention will be further described.

[0023] 2 is a perspective view of the appearance of the first embodiment of the heat pipe performance detection device of the present invention, FIG. 3 is a perspective exploded view of FIG. 2, and FIG. 4 is a perspective view of the cover in FIG. 3. The detection device mainly includes a fixed part 20 and a movable part 30. among them:

[0024] The fixed portion 20 is a fixed part that is locked on a stable platform such as a test table or other supporting mechanism, and is made of a material with good thermal conductivity. The fixed portion 20 is provided with a flow channel for the cooling liquid to pass through (not shown in the figure) ), and is connected to an external constant temperature cooling liquid circulation system (not shown) through the cooling liquid inlet and outlet joint 22. The surface of the fixed portion 20 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com