Nuclear and chemical injury washing and cleaning device

A decontamination and nucleation technology, which is applied to bathing devices, chemical, and therapeutic atomizers, etc., can solve the problems of high manufacturing cost, complex structure, cumbersome operation, etc., and achieves low manufacturing cost, small size, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

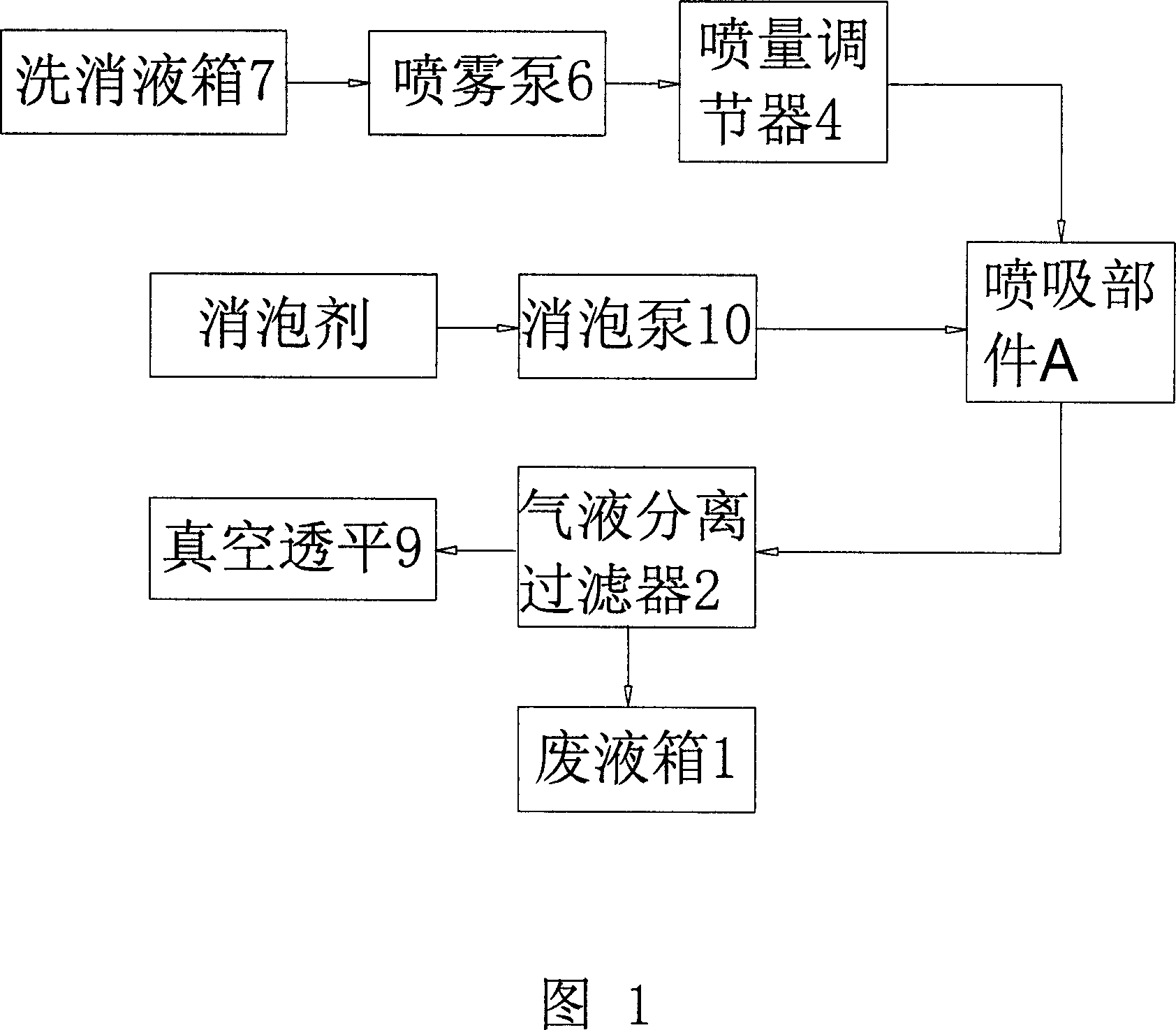

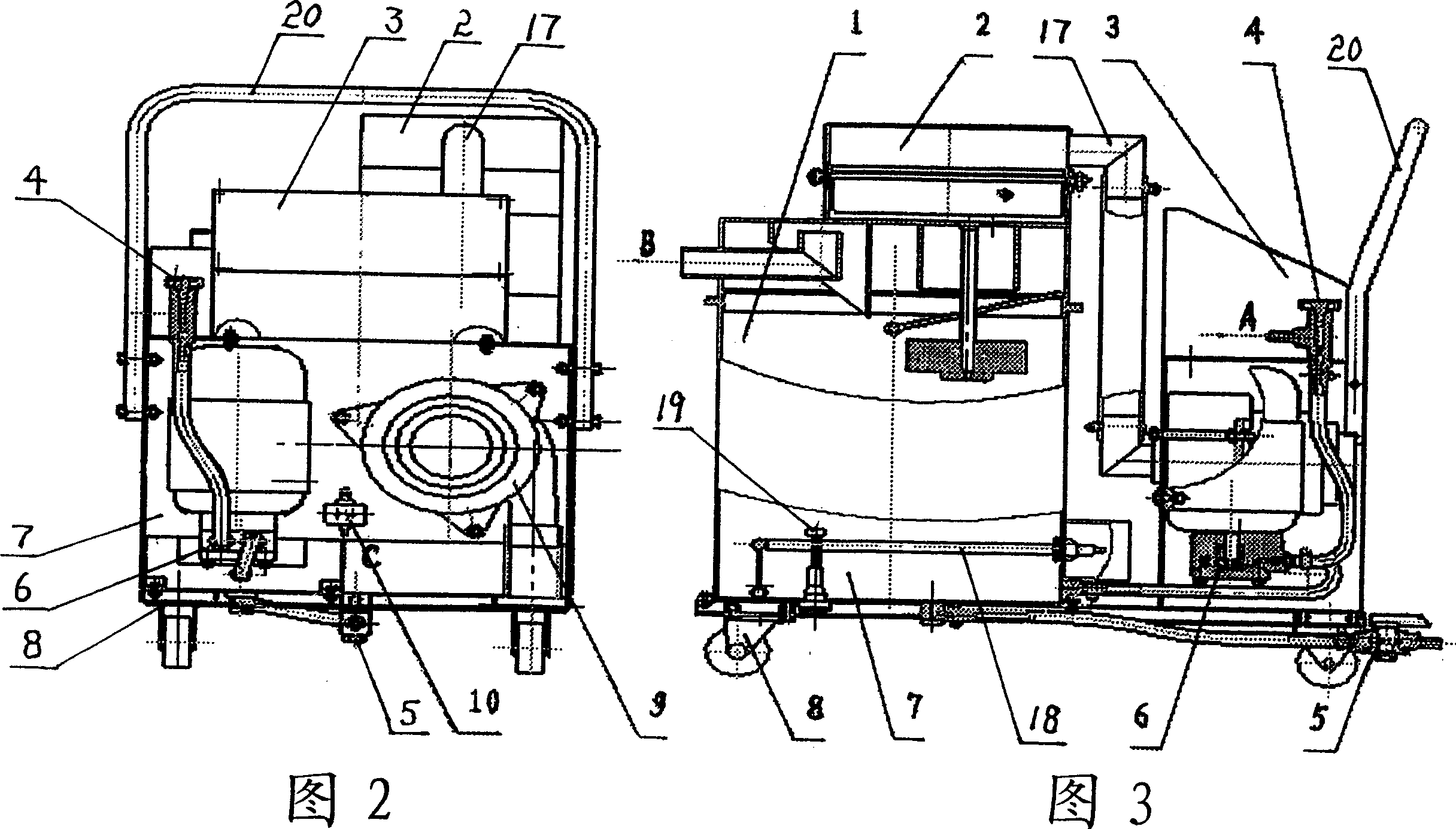

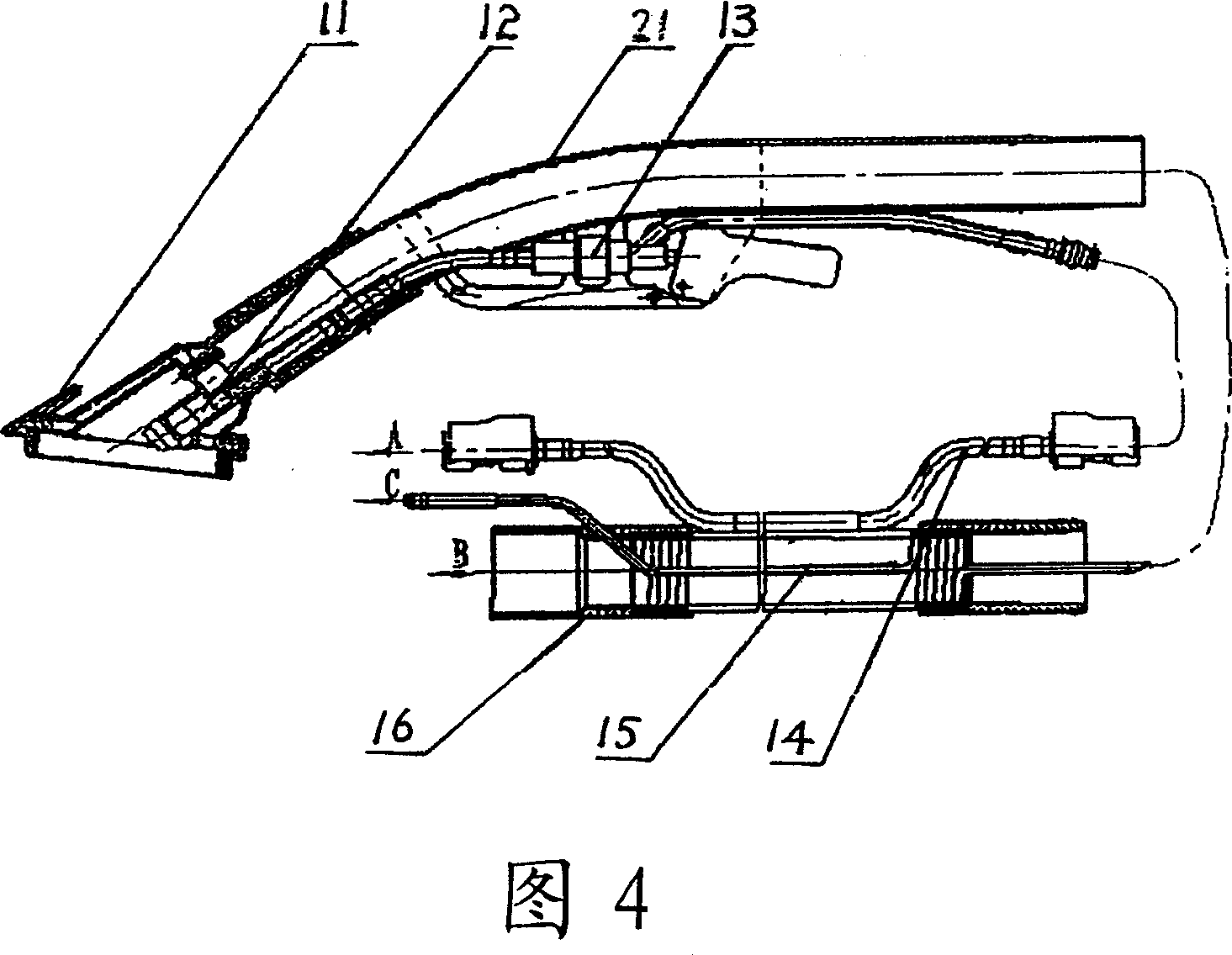

[0013] Referring to Fig. 1~Fig. 4, the decontamination liquid tank 7 of the present invention is connected with the nozzle interface (A-A) of the spray suction part D after the spray pump 6 and the spray volume regulator 4 are connected in series through the pipeline, and the defoamer of the spray suction part D Pipe 15 and suction pipe 16 interface are respectively connected with the outlet (C-C) of defoaming pump 10 and the inlet (B-B) of gas-liquid separation filter 2; The inlet is connected, and the liquid outlet of the gas-liquid separation filter 2 is connected to the waste liquid tank 1 , and a drain valve port 5 is provided at the bottom of the waste liquid tank 1 . An electric heater 18 and a liquid level sensor 19 are arranged in the decontaminant tank 7 . The spray pump 6, defoaming pump 10, vacuum turbine 9, electric heater 18 and liquid level sensor 19 are all connected with the electric control system (installed in the electric control box 3). Above-mentioned ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com