Preparation of shikimic acid

A technology of shikimic acid and technology, applied in the field of plant resources, can solve the problems of long industrialized production process, complicated operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

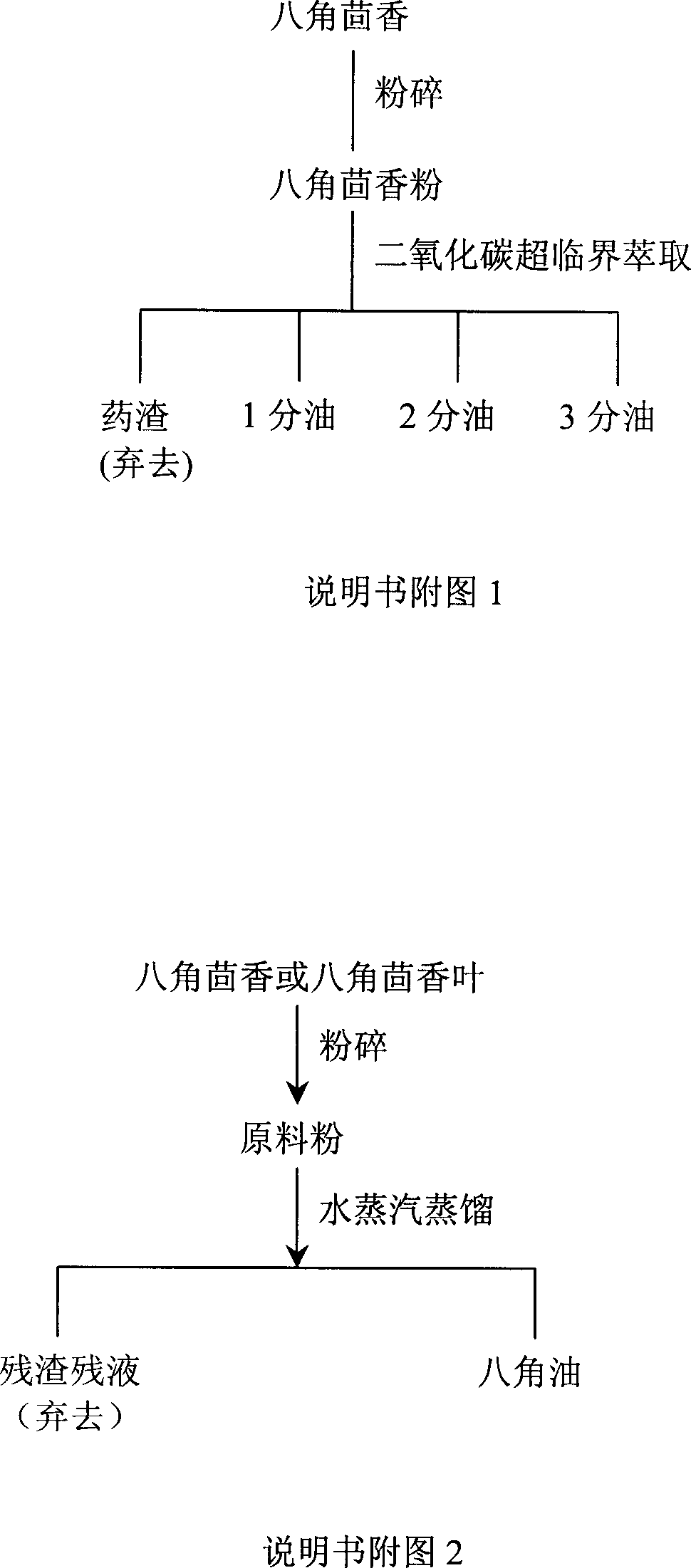

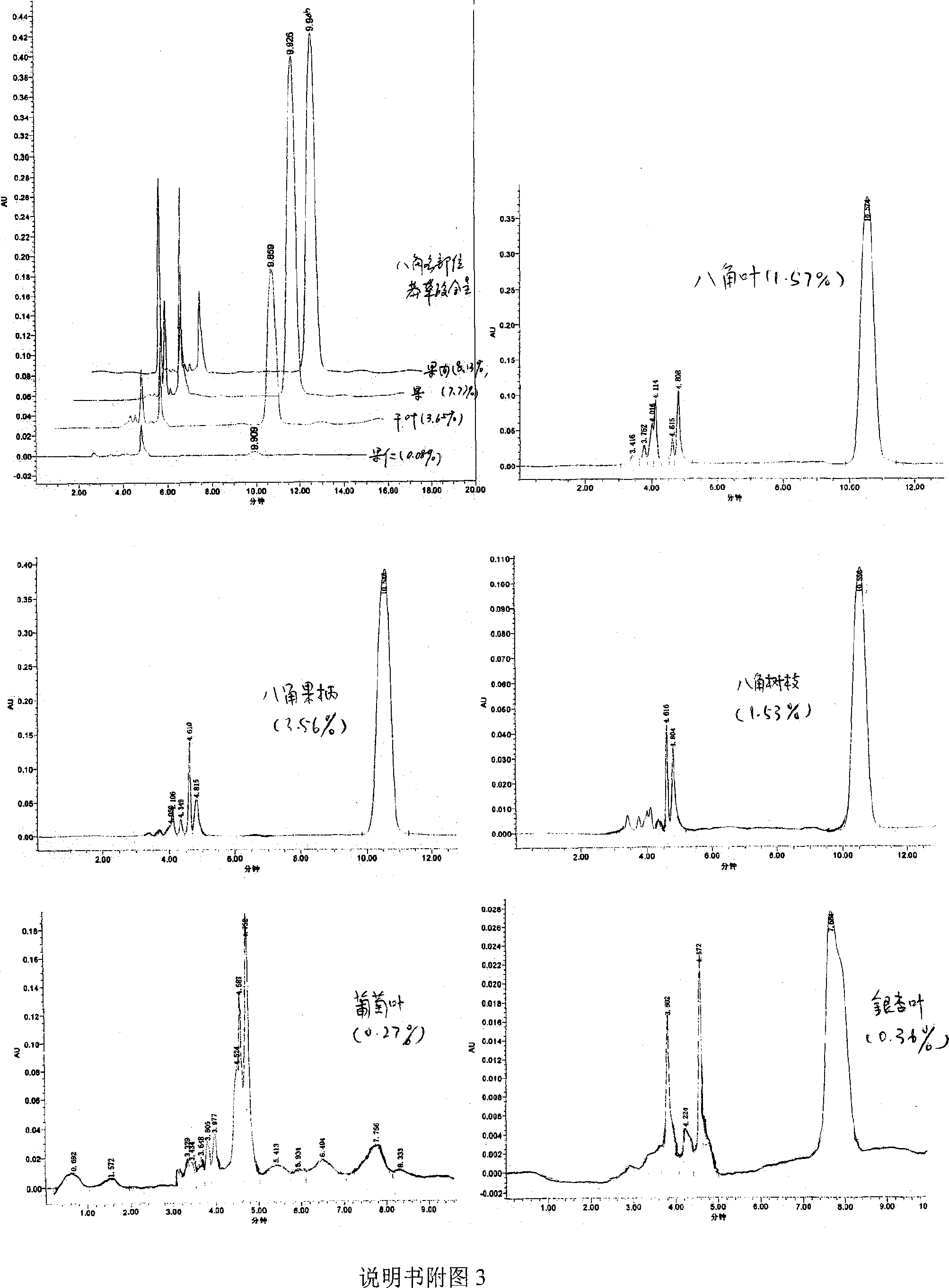

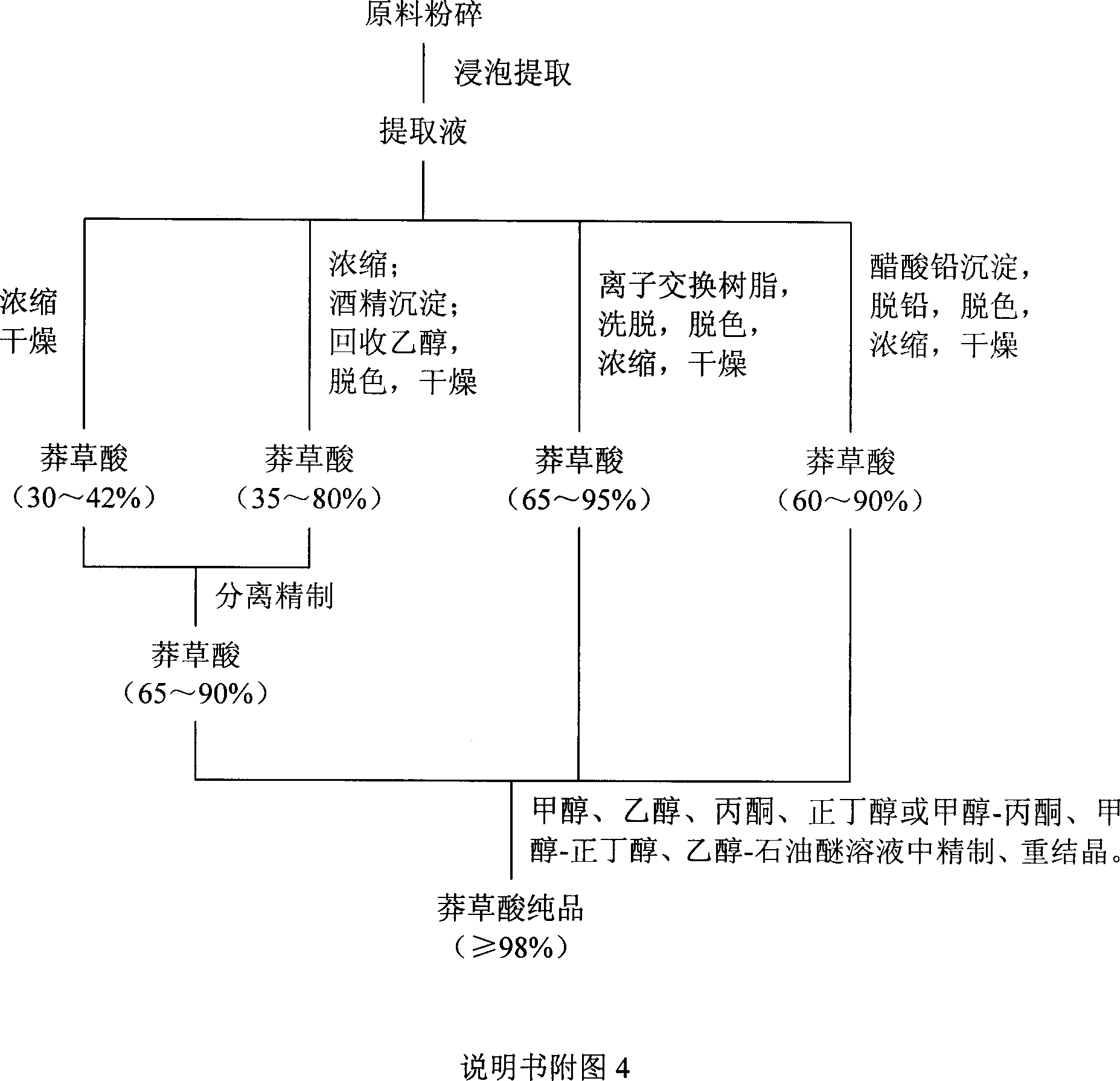

Method used

Image

Examples

Embodiment Construction

[0025] 1. Star anise, crushed, add 10 times the amount of water, stir from time to time, soak for 20 minutes, filter, collect the filtrate; add 8 times the amount of water, 6 times the amount of water to the residue, and operate in the same way. Combine the extracts, evaporate and concentrate to 2:1 (crude drug g / ml), add alcohol to 80% alcohol content, let it stand, filter the supernatant, recover ethanol, decolorize with activated carbon, dry, and the yield of shikimic acid is 4.32% ( Calculated according to shikimic acid, the same below), the content is 38.9%. The residue can be used to extract star anise oil.

[0026] 2. Star anise water steam distills the residue after extracting the star anise oil, filter the water, leave it in place, add 10 times more water to the residue and decoct for 1 hour, filter, combine the two filtrates, concentrate to 2:1 (raw material g / ml), Add alcohol to 80% alcohol content, precipitate, filter, take the filtrate to flow out through D101 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com