Methods of forming alpha and beta tantalum films with controlled and new microstructures

A microstructure and thin film technology, applied in the field of tantalum thin films, can solve problems such as unsatisfactory thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

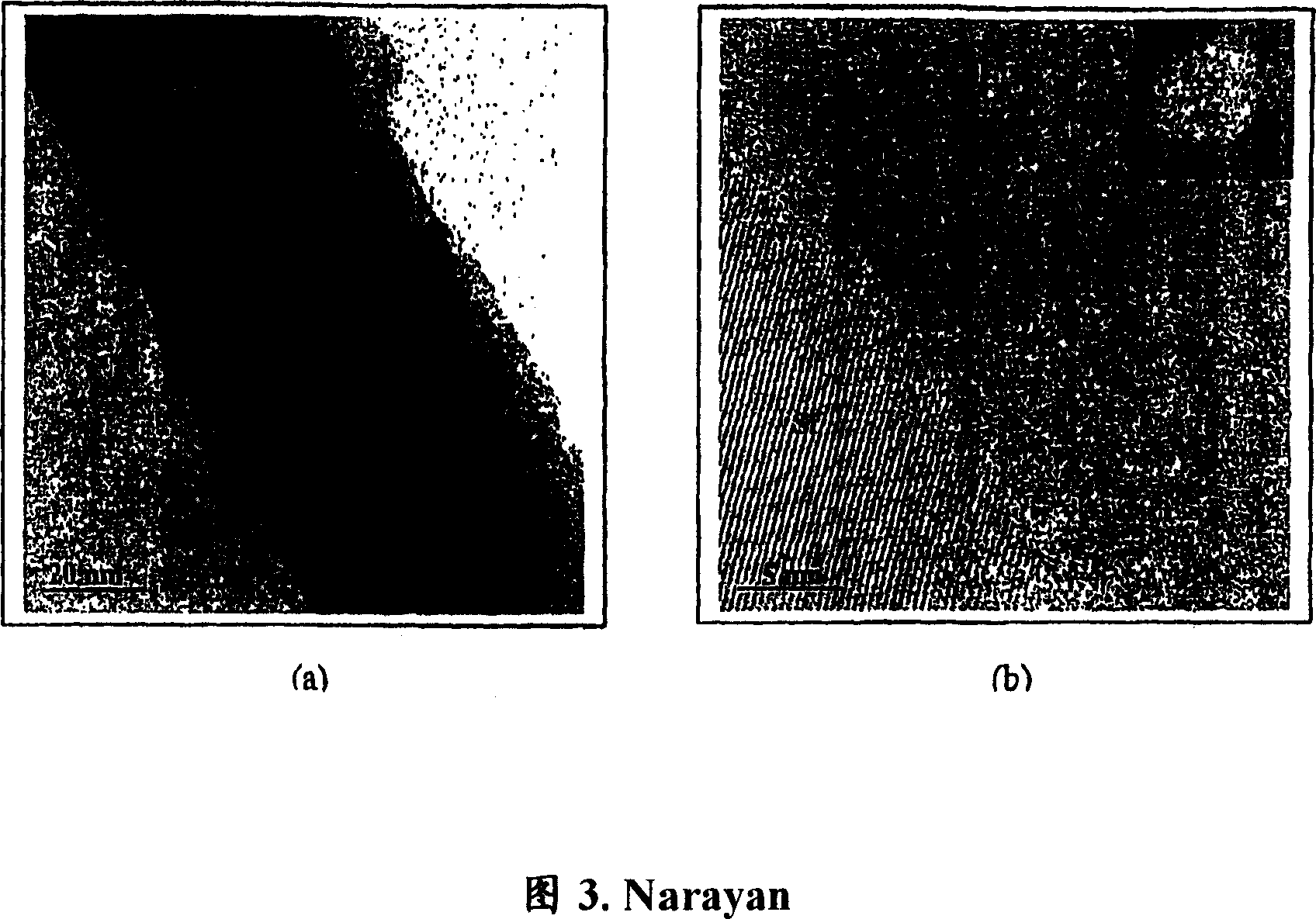

[0052] Scanning Transmission Electron Microscopy Z-contrast images (STEM Z) provide contrast for individual elements based on atomic number (Z2 dependent) differences. Electron Energy Loss Spectroscopy (EELS) analyzes composition by detecting the electronically characteristic energy loss of specific elements. These methods are all powerful tools for the determination of Cu diffusion maps with high precision (0.16 nm spatial resolution), compared to SIMS maps with a resolution of the order of 10 nm. Therefore, HRTEM, STEM-Z contrast images, EELS, atomic structure images, and compositional analyzes were performed on α-Ta thin films with amorphous to single-crystalline microstructures, and the results were compared with large-area SIMS.

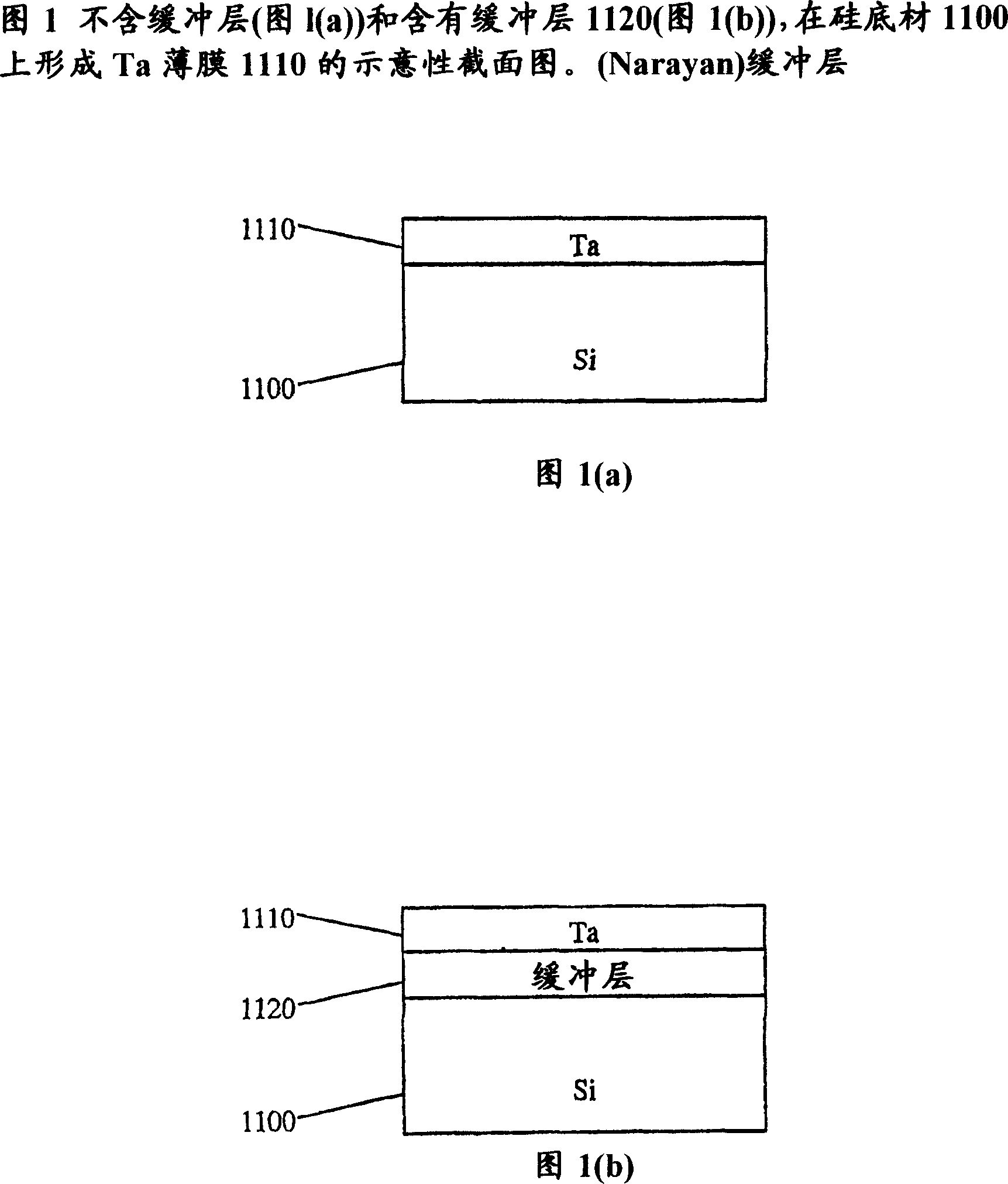

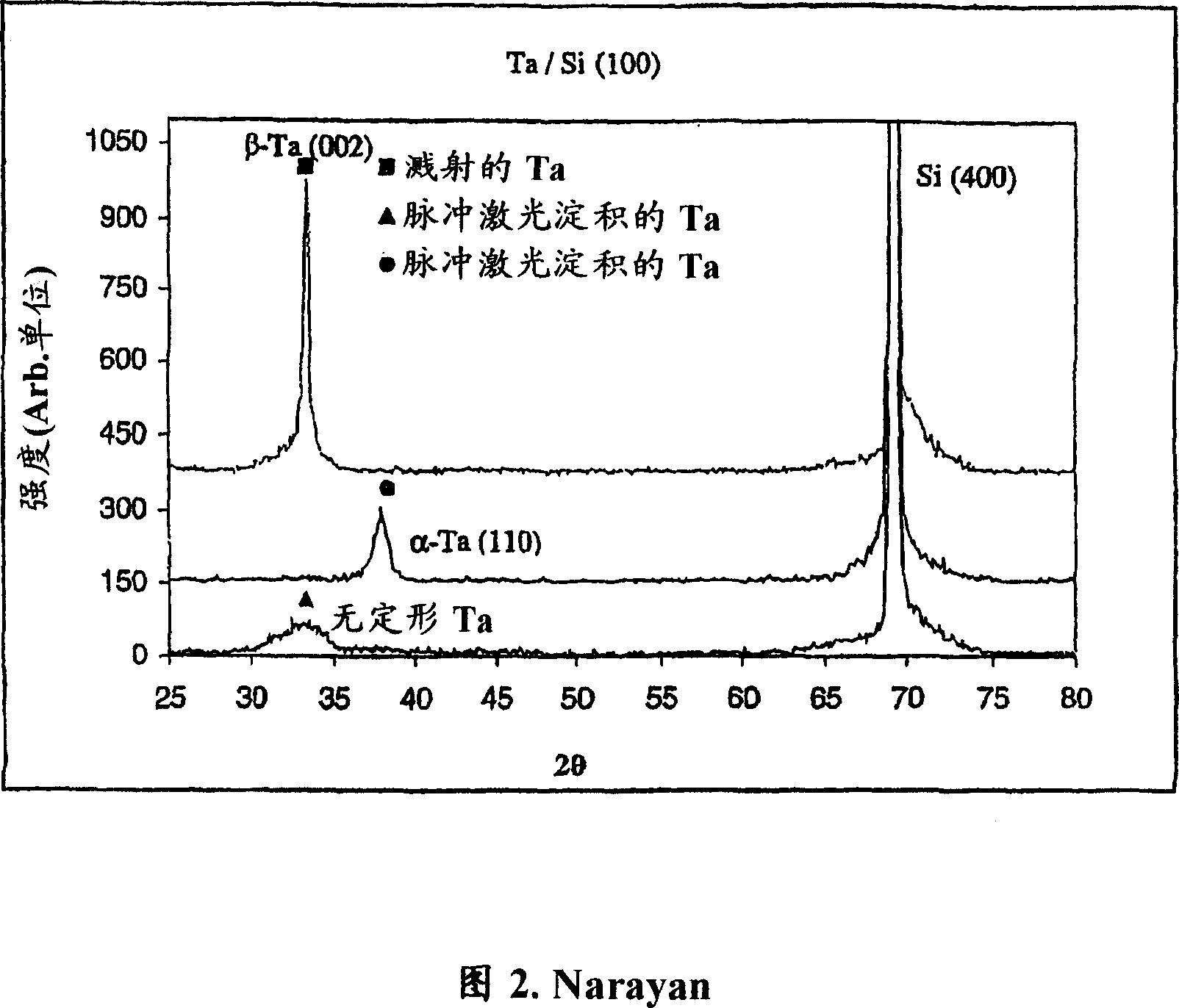

[0053]Tantalum (α-Ta) thin films with amorphous to nanocrystalline to polycrystalline to single crystalline microstructures were formed on silicon (Si) substrates with and without buffer layers. Alpha-tantalum (α-Ta) films with grain sizes rang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com