Integrated photoelectronic registration and shaftless transmission control system for intaglio printing machine in a set

A gravure printing machine and shaftless transmission technology, which is applied to printing machines, electrical program control, general parts of printing machinery, etc., can solve the problems of poor control accuracy and complex mechanical structure, and achieve stable control performance, simplified mechanical structure, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

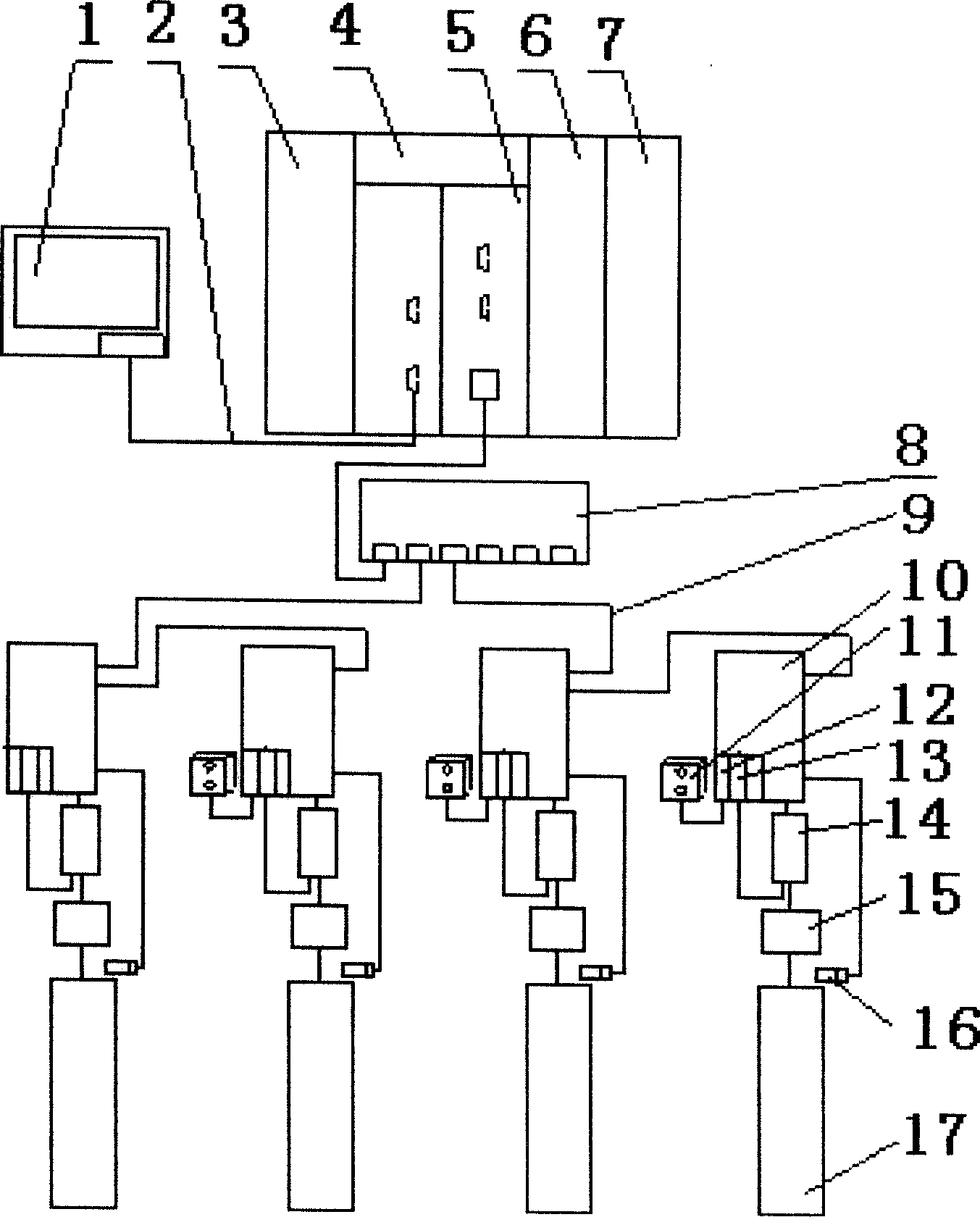

[0015] Referring to Fig. 1, the photoelectric registration and shaftless transmission integrated control system of the unit gravure printing machine of the present invention combines the photoelectric registration control system and the shaftless transmission control system together. It is composed of PCC power supply module 3, CPU module 4, communication card 5, analog input module 6 and analog output module 7. It consists of a lower computer, a second network communication cable 2, a touch screen 1 (upper computer), HUB interface 8, POWERLINK bus 9, servo driver 10 (ACOPOS) and servo motor 14, photoelectric eye 11, cursor signal analysis card 12, encoder signal analysis card 13, zero point confirmation proximity switch 15, mechanical deceleration mechanism 16, and printing plate roller 17 constitute the control executive body.

[0016] The lower computer completes the compilation of the control program of the whole system and realizes the specific process and data processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com