Improved neutron absorption effectiveness for boron content aluminum materials

A neutron, composite material technology, used in the control of nuclear reactions, volume/mass flow generated by mechanical effects, reduction of greenhouse gases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

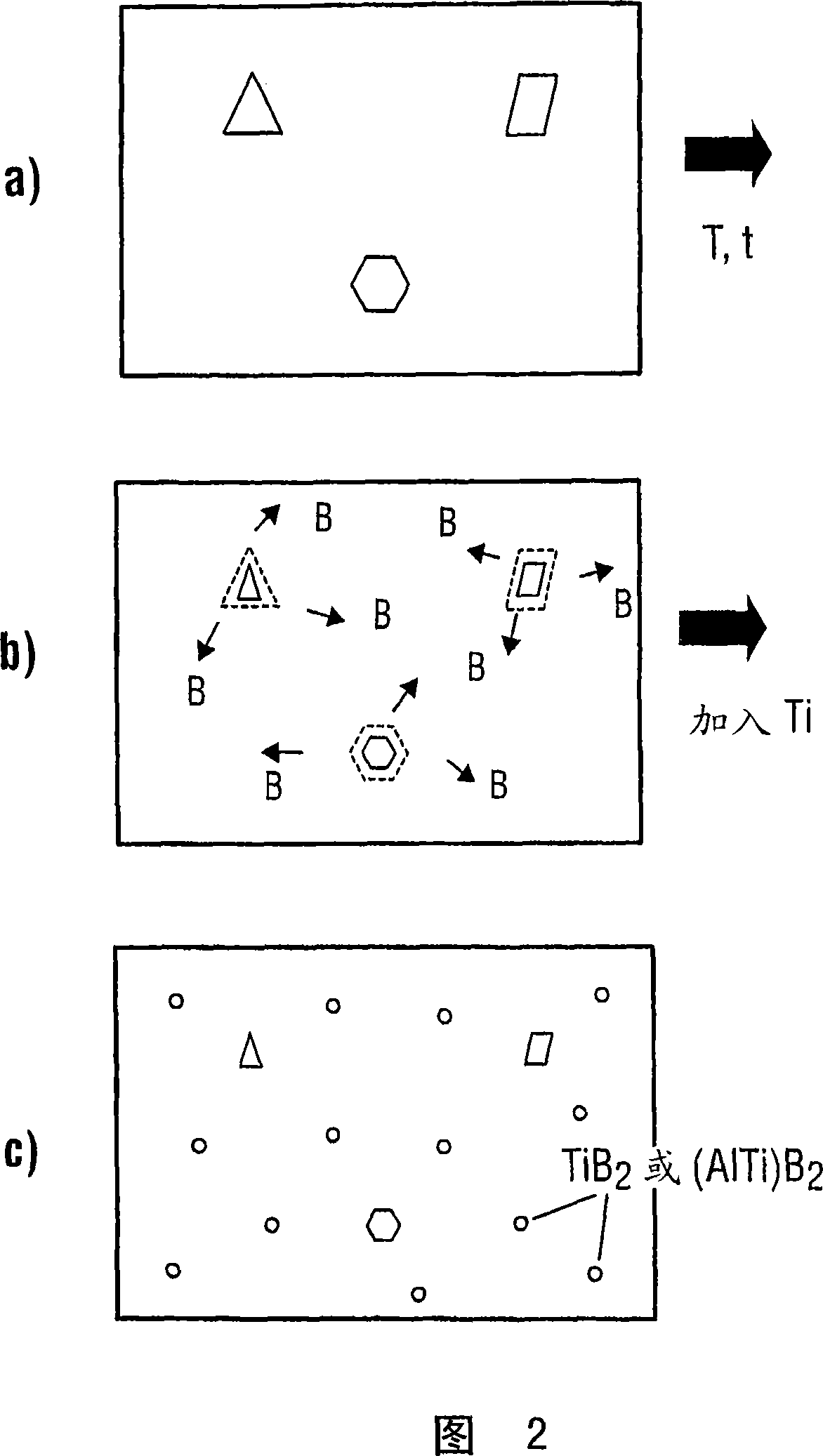

[0045] Al-2.5wt%B alloys were prepared using a commercial Al-4%B master alloy. A microscopic view of a solid sample of the prepared material is shown in Figure 4, which graphically illustrates the large AlB 2 Characterization of intermetallic compound particles. After melting, the material was kept at 800 °C for 2 h to partially dissolve the original large boron-containing particles (AlB 2 ). Thereafter, 0.7wt% Ti was added to the molten metal to form many fine boron-containing species (TiB 2 or (AlTi)B 2 ) and the composite material is subsequently cast into the form of an ingot. Figure 5 is a micrograph of specimens taken from an ingot, showing that these fine specimens are evenly located within the larger AlB of the original cast alloy 2 between particles.

Embodiment 2

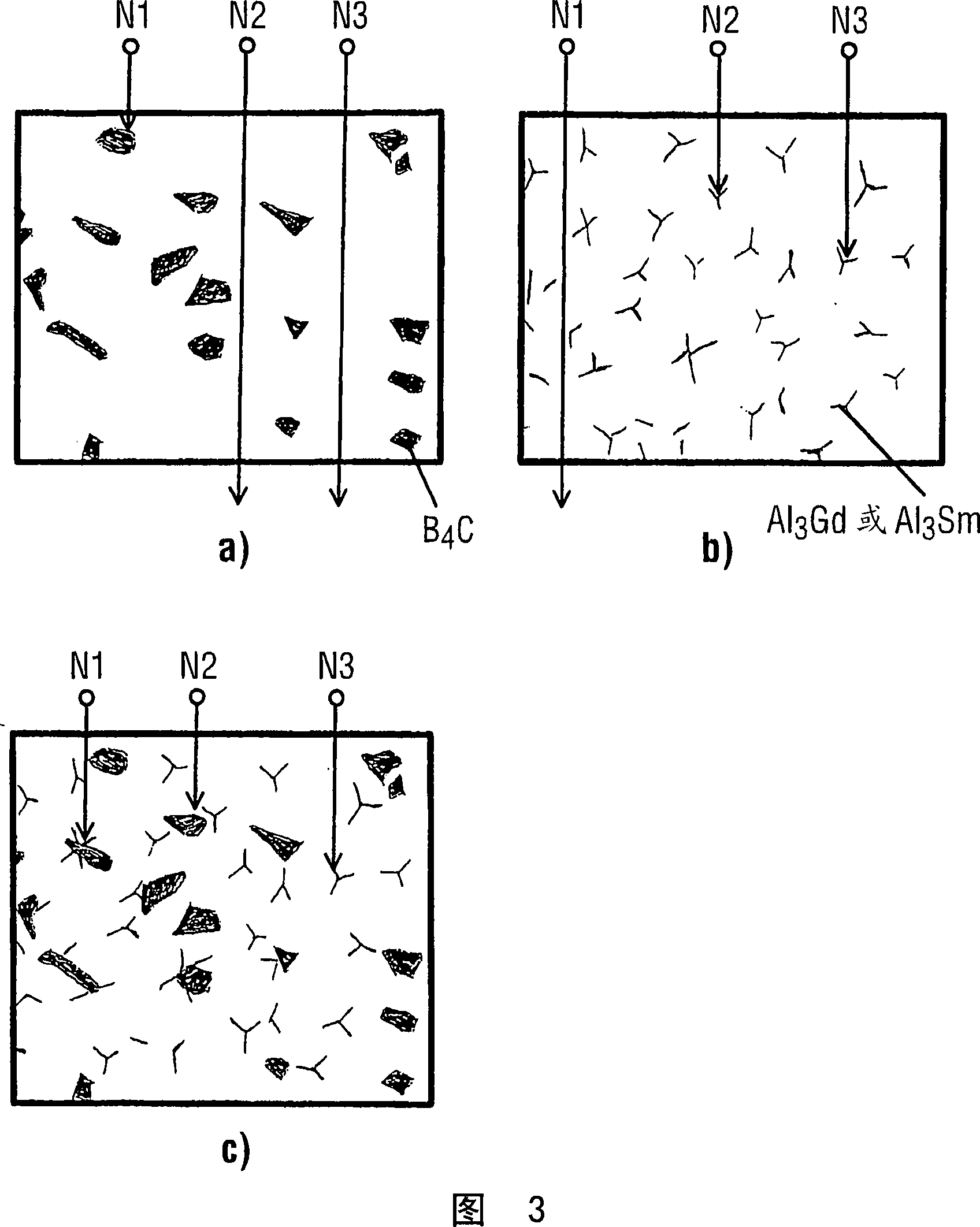

[0047] Al-1.0wt%B alloys were first prepared using a commercial Al-4%B master alloy. After melting, 3.0wt% B 4 C powder is added to the molten metal to form Al-B 4 C-B composites. The molten composite was kept at 800 °C for 2 h to partially dissolve the original large boron-containing particles (AlB 2 and B 4 C). Thereafter, 0.3wt% Ti was added to the molten composite, which was subsequently cast in the form of a cylindrical ingot. Figure 6 illustrates a sample taken from an ingot cast from a composite material thus treated, showing numerous in situ formed fine boron-containing species (TiB 2 or (AlTi)B 2 ), which is well distributed to fill the larger AlB 2 and B 4 C gaps between particles.

Embodiment 3

[0049] Preparation of Al-B 4 C-Gd composites. First, 2wt% Gd was added to molten aluminum for batch processing into Al-2%Gd alloy. followed by 8wt% B 4 C powder is added to this molten alloy to form Al-8B 4 C - 2% Gd composite, after which the composite was cast in the form of a cylindrical ingot. A sample of the cast ingot was taken, and Figure 7 shows a microscopic view of the sample, illustrating that during solidification of the ingot, fine Gd-Al intermetallics formed and tended to occupy the aluminum grain boundaries. In casting Al-B 4 Combining these intermetallic compounds in C composites greatly reduces the larger neutron-absorbing compounds (B 4 C) The gap between.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com