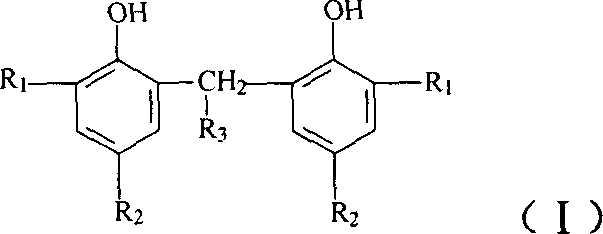

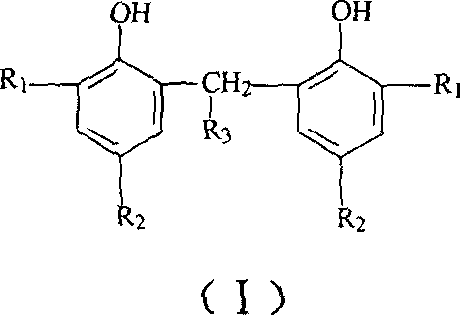

Cleaning production method for preparing bisphenol compound antioxidant product

A clean production and antioxidant technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve environmental hazards and other problems, and achieve the effect of simplifying the production operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

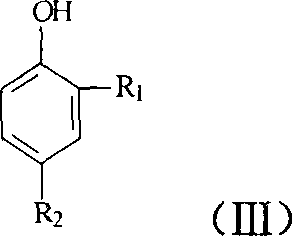

Method used

Image

Examples

Embodiment 1

[0039] In a 1000mL four-necked flask with a thermometer, a stirrer, a reflux condenser, and a dropping funnel, add 300 grams of 2,4-di-t-amylphenol, 380 grams of water, and the anionic surfactant dodecylbenzenesulfonic acid Sodium 2.5 grams, 98% sulfuric acid 18.5 grams. Paraldehyde 31.5 grams. Stir while heating. When the temperature of the reaction mixture rises to 92-93° C., the temperature is kept for 6 hours. After the reaction is finished, filter and collect the obtained filtrate as the reaction mother liquor for use. The filter cake was purified by recrystallization from absolute ethanol to obtain 276.2 g of white crystalline product of 2,2'-ethylene bis(4,6-ditentylphenol), with a melting point of 117.8-118.5°C.

Embodiment 2

[0041] Add the reaction mother liquor obtained in Example 1 into the four-necked flask in Example 1, add 300 grams of 2,4-di-t-amylphenol, and 31.5 grams of paraldehyde. Stir while heating. When the temperature of the reaction mixture rises to 92-93° C., the temperature is kept for 6 hours. After the reaction is finished, filter and collect the obtained filtrate as the reaction mother liquor for use. The filter cake was purified by recrystallization from absolute ethanol to obtain 282.6 g of white crystalline product of 2,2'-ethylene bis(4,6-ditentylphenol), with a melting point of 118.0-118.7°C.

Embodiment 3

[0043]The reaction mother liquor obtained by recycling the fifth time in Example 1 was added to the four-necked flask in Example 1, and 300 grams of 2,4-di-t-amylphenol and 31.5 grams of paraldehyde were added. Stir while heating. When the temperature of the reaction mixture rises to 92-93° C., the temperature is kept for 6 hours. After the reaction is finished, filter and collect the obtained filtrate as the reaction mother liquor for use. The filter cake was purified by recrystallization from absolute ethanol to obtain 279.6 g of white crystalline product of 2,2'-ethylene bis(4,6-di-t-amylphenol), with a melting point of 117.8-118.3°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com