Intelligent diagnosis and determination support system for blast furnace

A decision support system and intelligent diagnosis technology, applied in blast furnaces, blast furnace details, general control systems, etc., can solve problems such as lack of data and analysis methods for process improvement, time-consuming and error-prone hand-written reports, one-sidedness of furnace conditions, etc., to achieve high The effect of reducing the burden due to fewer components and testing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

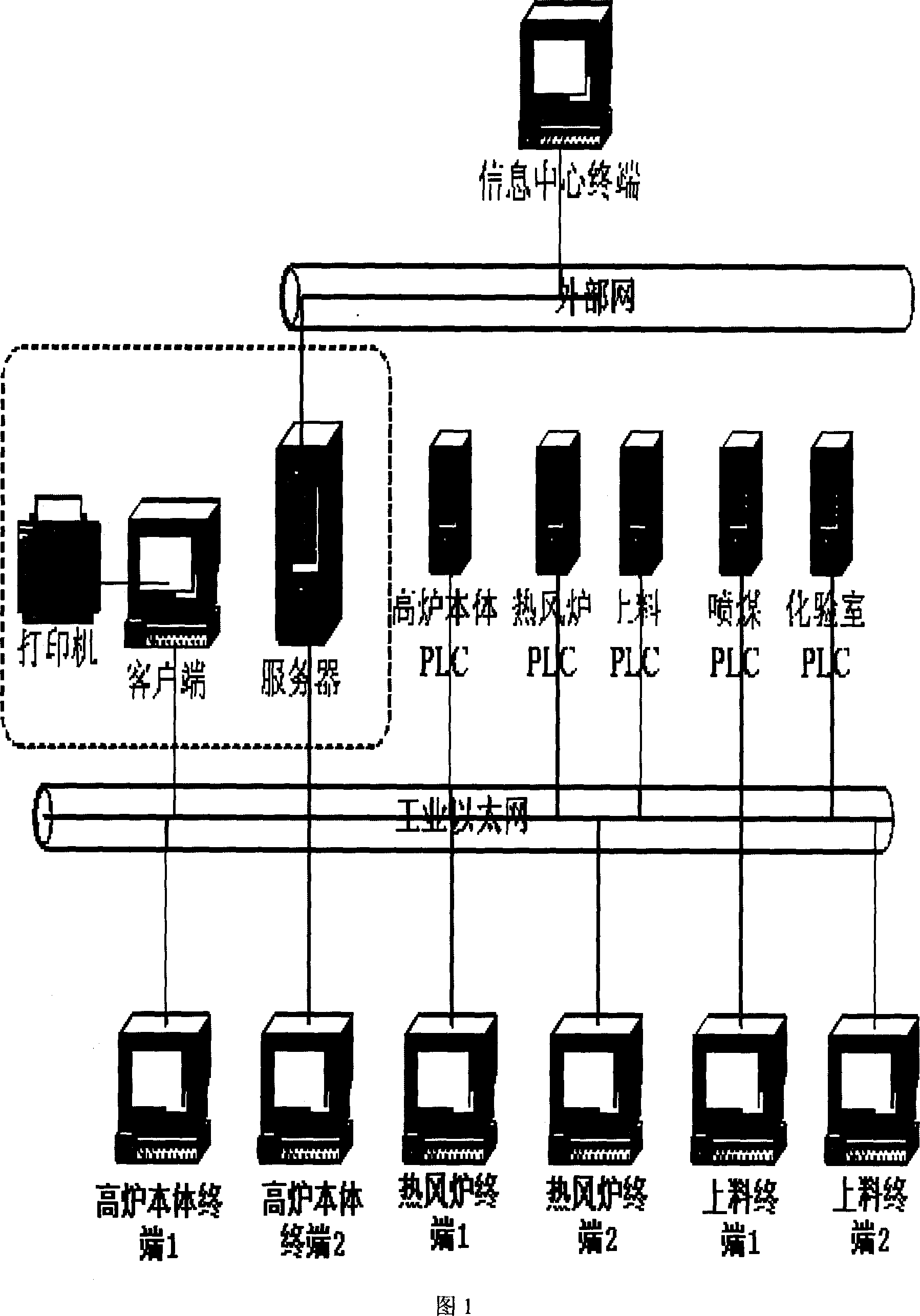

[0027] Referring to the part outside the dotted line in Figure 1, the ironworks originally located in the main control room had two industrial computers for monitoring the main body of the blast furnace, two industrial computers for monitoring feeding, and two industrial computers for monitoring the hot blast stove. The PLC for collecting data included the blast furnace Main body PLC, hot blast stove PLC, feeding PLC, coal injection PLC, laboratory PLC constitute the production LAN. The present invention adds two computers in the main control room: a server, a client, and a printer, as shown in the dotted line in Figure 1. Among them, the server can be connected with the information center and factory office through the company network. Clients can be increased to multiple, as long as they can connect to the server.

[0028]When the foreman conducts production management on the client, if he uses the blast furnace batching calculation Excel program to carry out batching, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com