Ground intensity detector

A strength detection and ground technology, applied in the direction of applying stable tension/pressure to test the strength of materials, roads, road repairs, etc., can solve the problems that cannot truly reflect the bearing capacity and the ground strength cannot be accurately reflected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

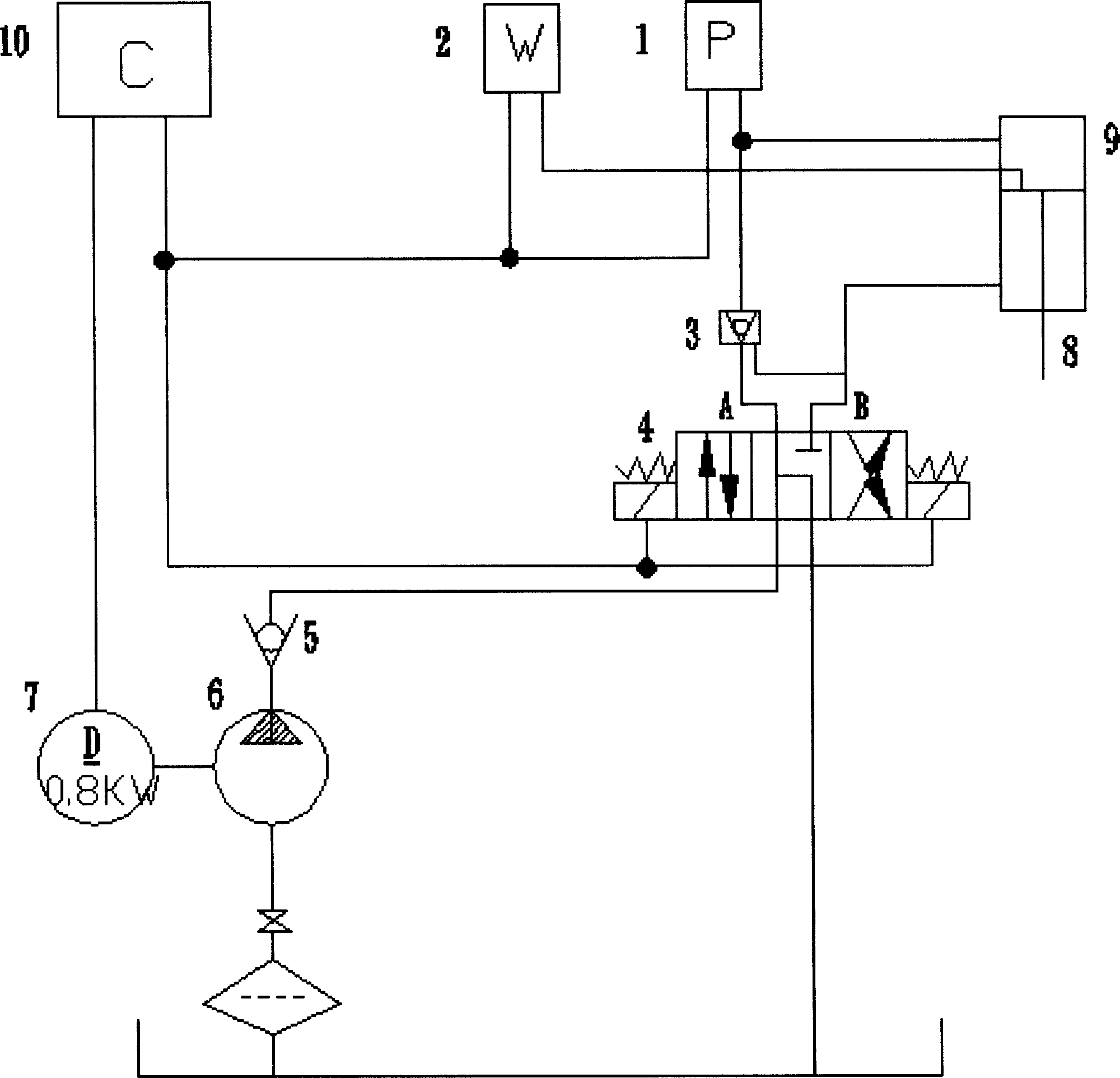

[0012] as the picture shows. When the user detects the ground strength, the controller 10 starts the motor 7 to drive the hydraulic pump 6 to output hydraulic oil to flow through the check valve 5, the electromagnetic reversing valve 4, and the hydraulic control check valve 3 into the hydraulic cylinder 9, so that the hydraulic cylinder piston rod 8 Stretch down. The displacement sensor 2 fixed on the piston rod 8 of the hydraulic cylinder moves down and measures the displacement of the piston rod 8 of the hydraulic cylinder. After the flat circular hinged contact at the front end of the piston rod 8 of the hydraulic cylinder touches the ground, under the action of the reverse force on the ground, the oil pressure in the rodless chamber of the hydraulic cylinder 9 rises and acts on the ground through the hinged contact. The reverse force is less than the force that the contact acts on the ground, and the contact pushes the ground to sink. When the oil pressure of the hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com