Multi-channel laser-triggered vacuum edge flashing switch

A technology of surface flashover and multi-channel, applied in the field of multi-channel laser-triggered surface flashover switch, can solve the problems of electrode ablation and easy pollution damage of insulating medium, achieve fast closing switch performance, realize long life and repetition frequency. Application, effect of improving efficiency and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

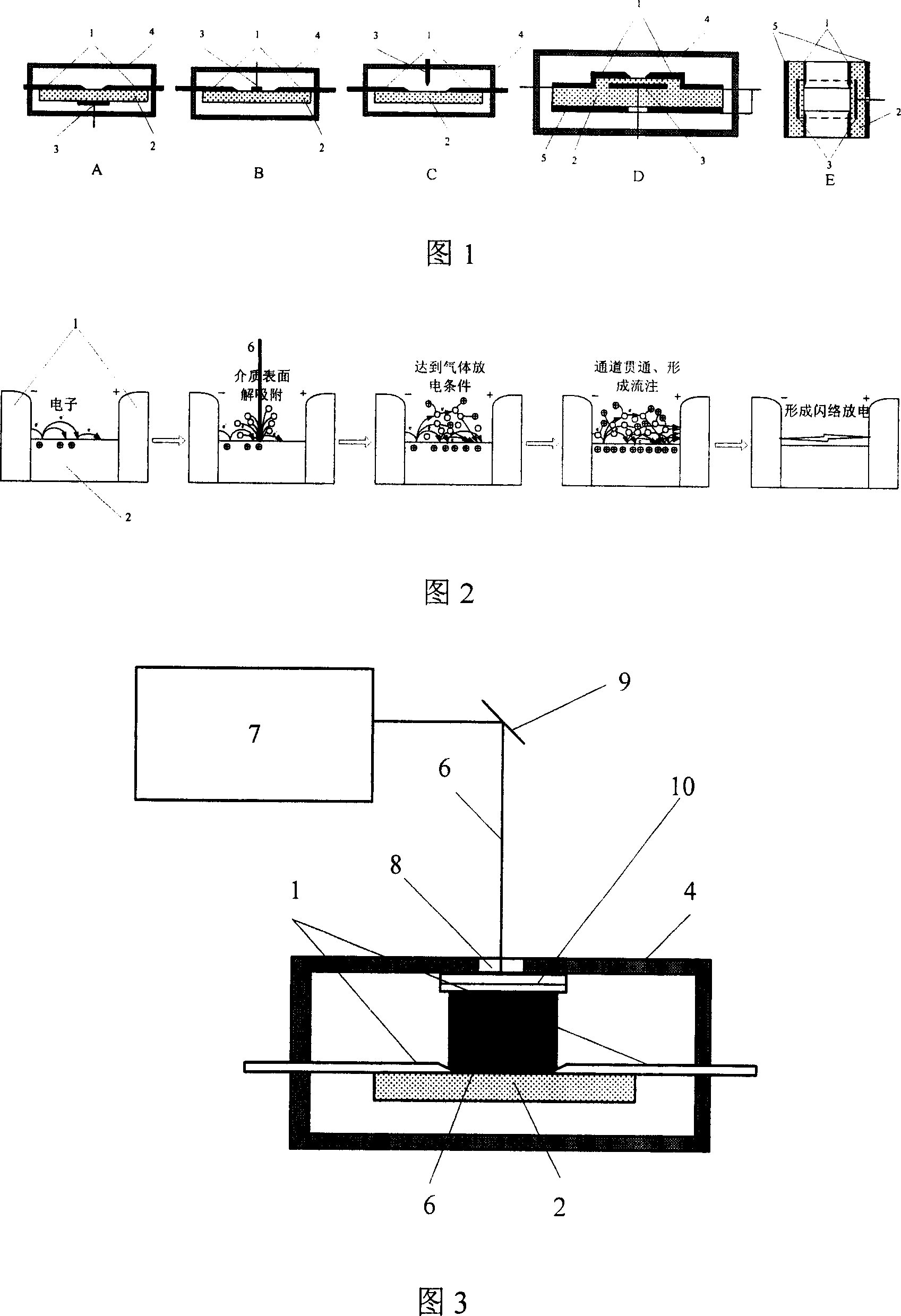

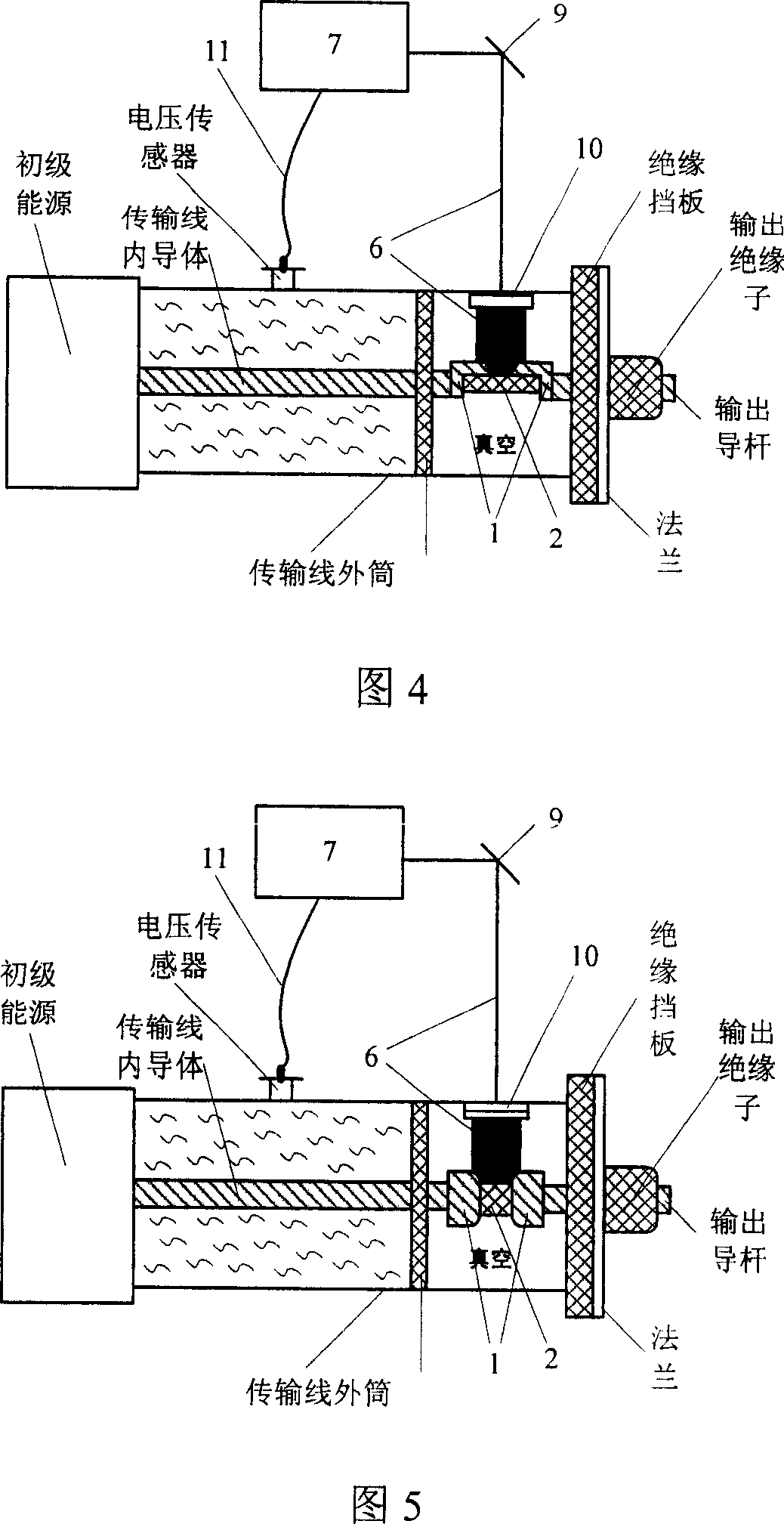

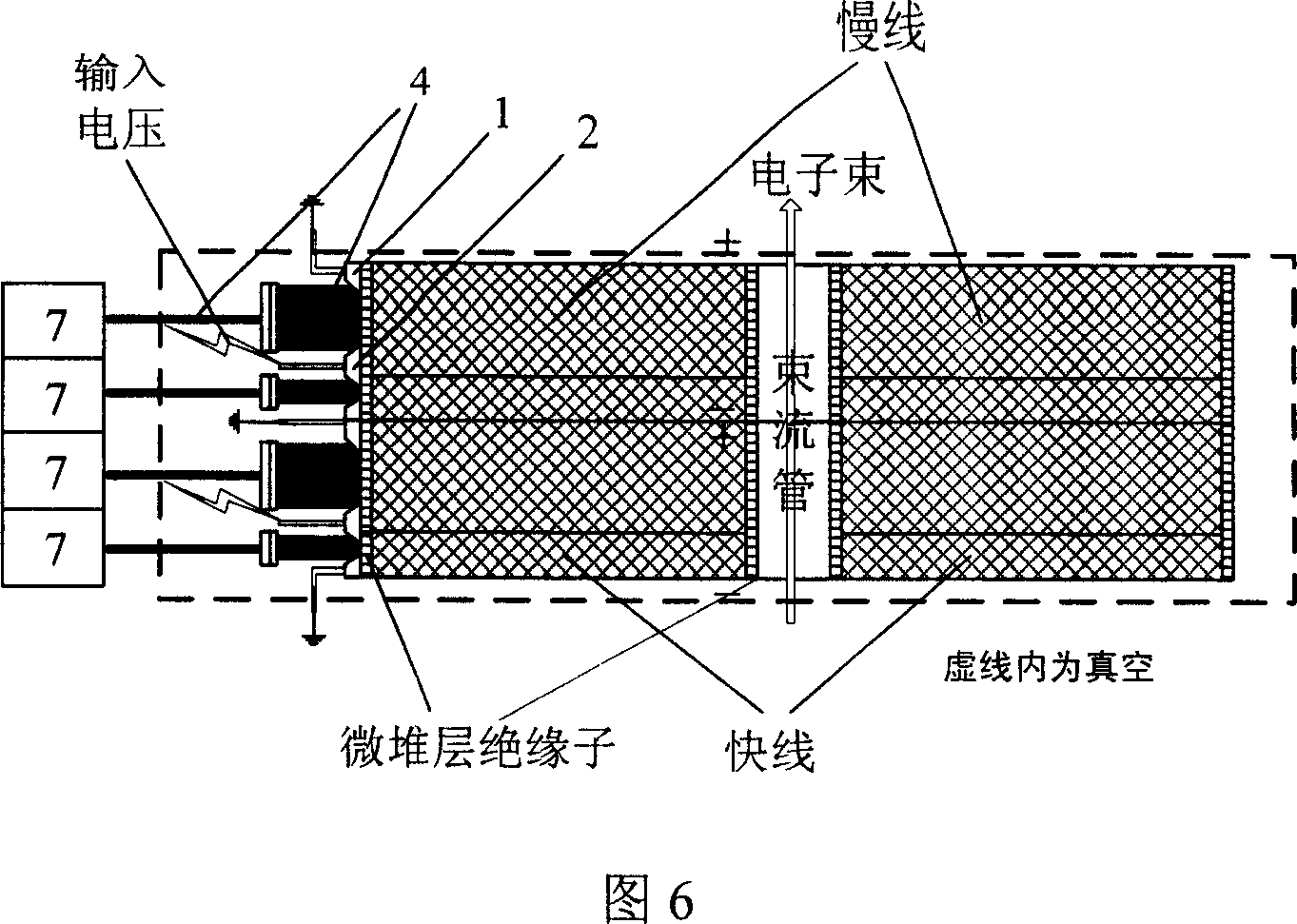

[0026] As shown in Figure 3, the multi-channel laser-triggered vacuum surface flashover switch of the present invention includes two parts: discharge work and trigger. The discharge work part is mainly composed of positive and negative electrodes 1, surface insulation medium 2, and insulation shell 4. Integrated together, there is no special insulating case4. The trigger part is composed of laser 7, laser transmission system 9, focusing system 10 and control system. The electrode 1 is tightly pressed on the surface of the insulating medium 2. On the basis of not destroying the mechanical and electrical properties of the insulating medium 2, it should be in close contact with the insulating medium 2 as much as possible. into the running line. The insulating casing 4 surrounds the electrode 1 and the insulating medium 2 of the switch in a vacuum environment. Electrode 1 stretches out from the both sides of insulating shell 4, and two ports will be sealed, and insulating shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com