Three-dimensional ceramic heater

a ceramic heater and three-dimensional technology, applied in the direction of heater elements, vacuum evaporation coatings, coatings, etc., can solve the problem of short working life and achieve the effect of reducing localized extra heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1 (

Not Claimed)

[0070]In Example 1, a pyrolytic boron nitride circular plate measuring 140 mm in diameter and 1 mm in thickness was made by reacting 4 slm (standard liter per minute) of ammonia with 2 slm of boron trichloride at a pressure of 10 Torr and a temperature of 1900 degrees centigrade. Next, a pyrolytic graphite layer of 50-micrometer thickness was formed on the circular plate by thermally cracking methane at a pressure of 5 Torr and a temperature of 1750 degrees centigrade; this layer was machine-cut into a heater pattern consisting of 8-mm-wide passages of heater element arranged to meander in the radial direction. As is seen in FIG. 9 (a), a pair of folded-back sections formed in the heater pattern are each divided—from a position E, at which the two folded-back sections face each other, through to a position 30 mm away from the position E—into two 4-mm-wide electric current lanes 18 and 19, the lane 18 being the inner lane at the folded-back section and the lane 19 being t...

example 2

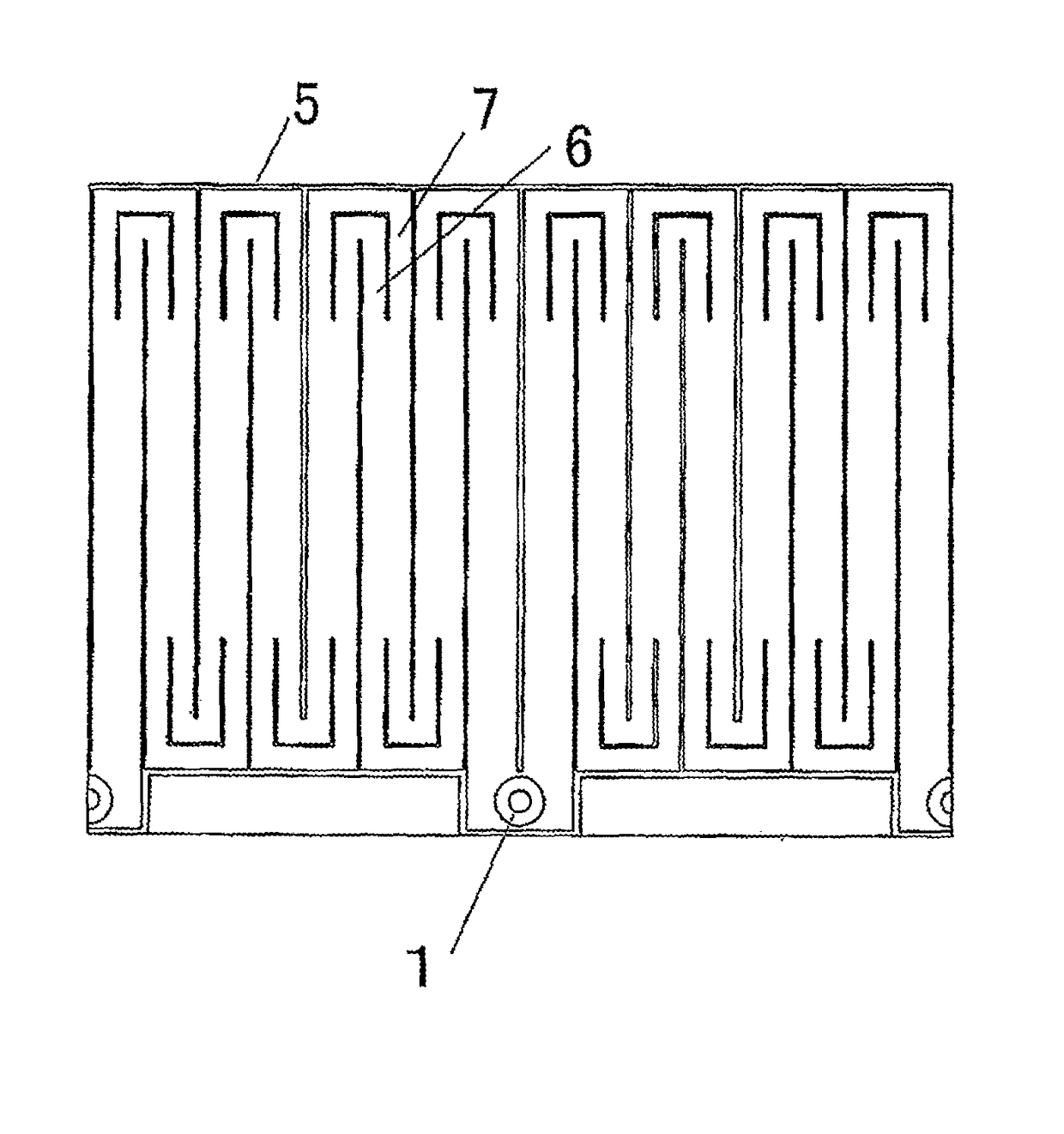

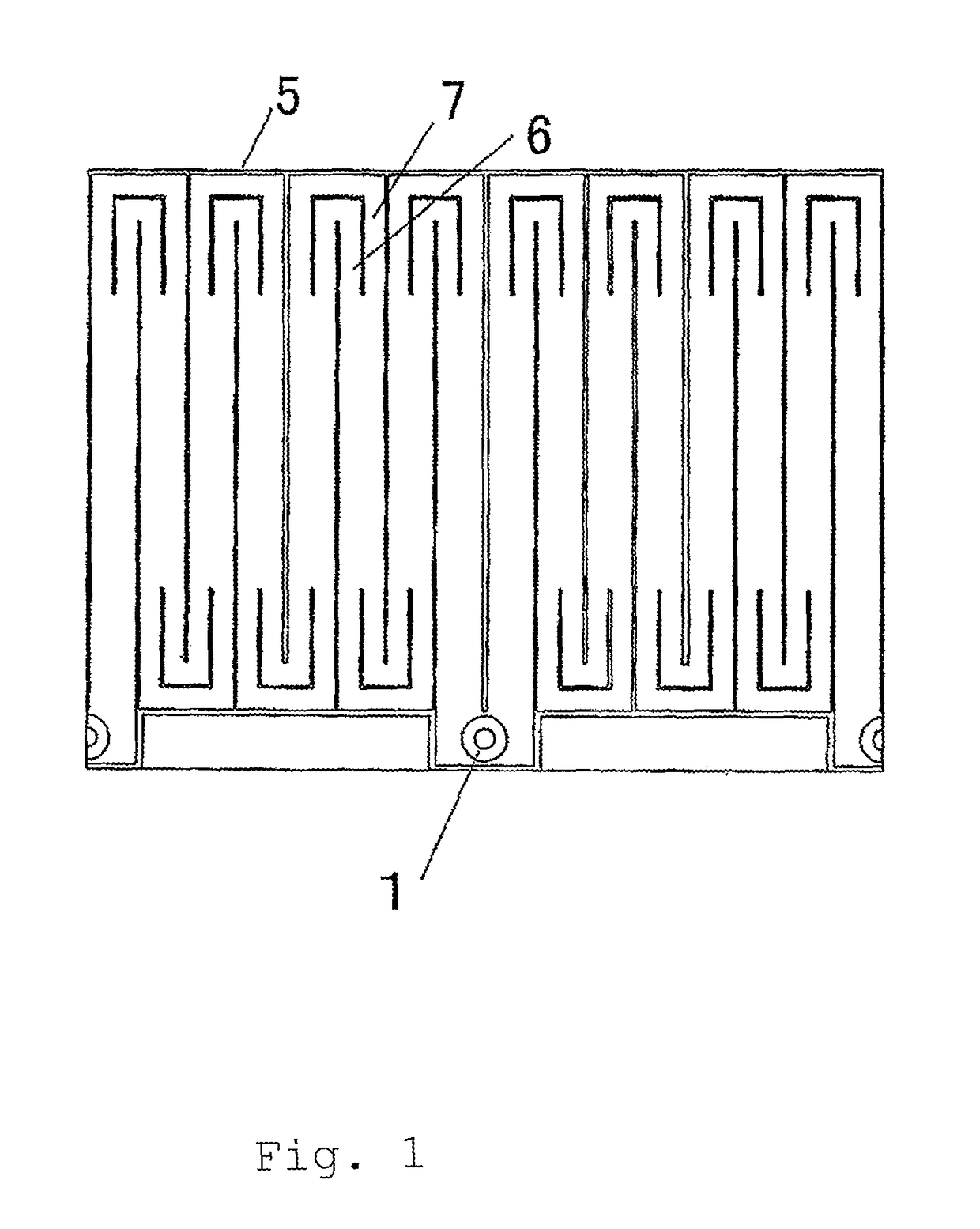

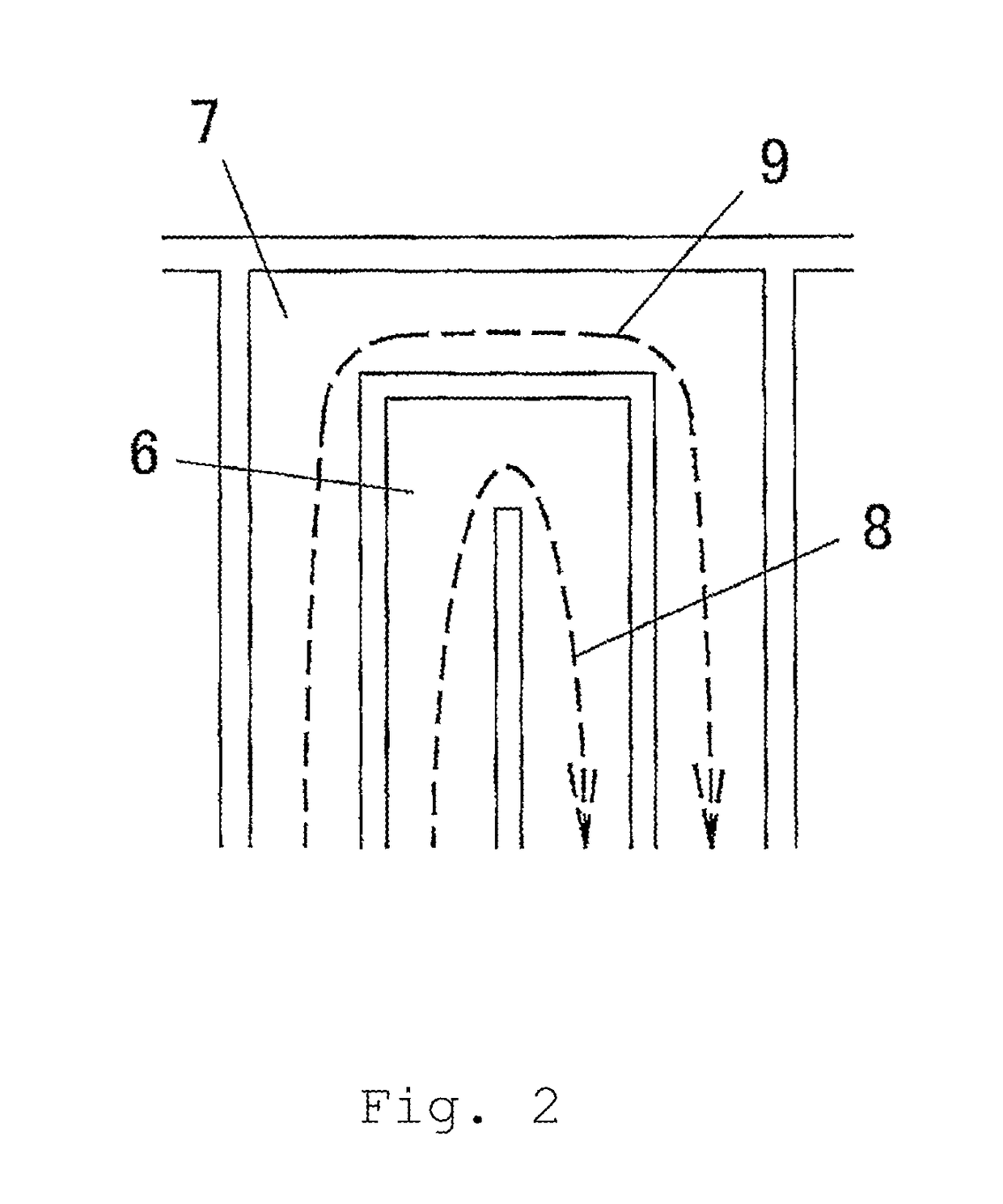

[0075]In Example 2, a pyrolytic boron nitride circular cylinder measuring 85 mm in outer diameter, 200 mm in height and 1.3 mm in thickness was made by reacting 4 slm of ammonia with 2 slm of boron trichloride at a pressure of 10 Torr and a temperature of 1900 degrees centigrade. Next, a pyrolytic graphite layer of 40-micrometer thickness was formed on the circular cylinder by thermally cracking methane at a pressure of 5 Torr and a temperature of 1750 degrees centigrade; this layer was machine-cut into a heater pattern as shown in FIG. 4. In this heater pattern the passage between the two electric power supply terminals 1, including the passage section between a folded-back section 14 and the closest electric power supply terminal and the passage section between the folded-back section 15 and the closest electric power supply terminal, was divided into an electric current lane 16 and an electric current lane 17, which extended continuously in parallel with the direction of the curr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com